6

NOTES:

1) TERMINAL BLOCK MARKINGS ARE FOR GOODMAN/AMANA

AIR HANDLERS.

NOMENCLATURE

EHR -EMERGENCY HEAT RELAY (OPTIONAL)

COLOR CODES

BL-- BLUE

BR--BROWN

GR--GREEN

OR--ORANGE

RD--RED

WH-WHITE

Y--YELLOW

BL/PK--BLUE/PINK STRIPE

O

R

A

N

G

E

#18 GA. 5 WIRE

BL

O

W

BL

W

G

C

BLUE

W2

G

WHITE

GREEN

ROOM THERMOSTAT

HEAT PUMP

B

L

U

E

W

H

I

T

E

R

E

D

R

#18 GA. 7 WIRE

R

INDOOR UNIT

R

RED

W3

BROWN

BR

R

G

BR

BL

W2

C

O

Y

R

Y

O

C

G

R

E

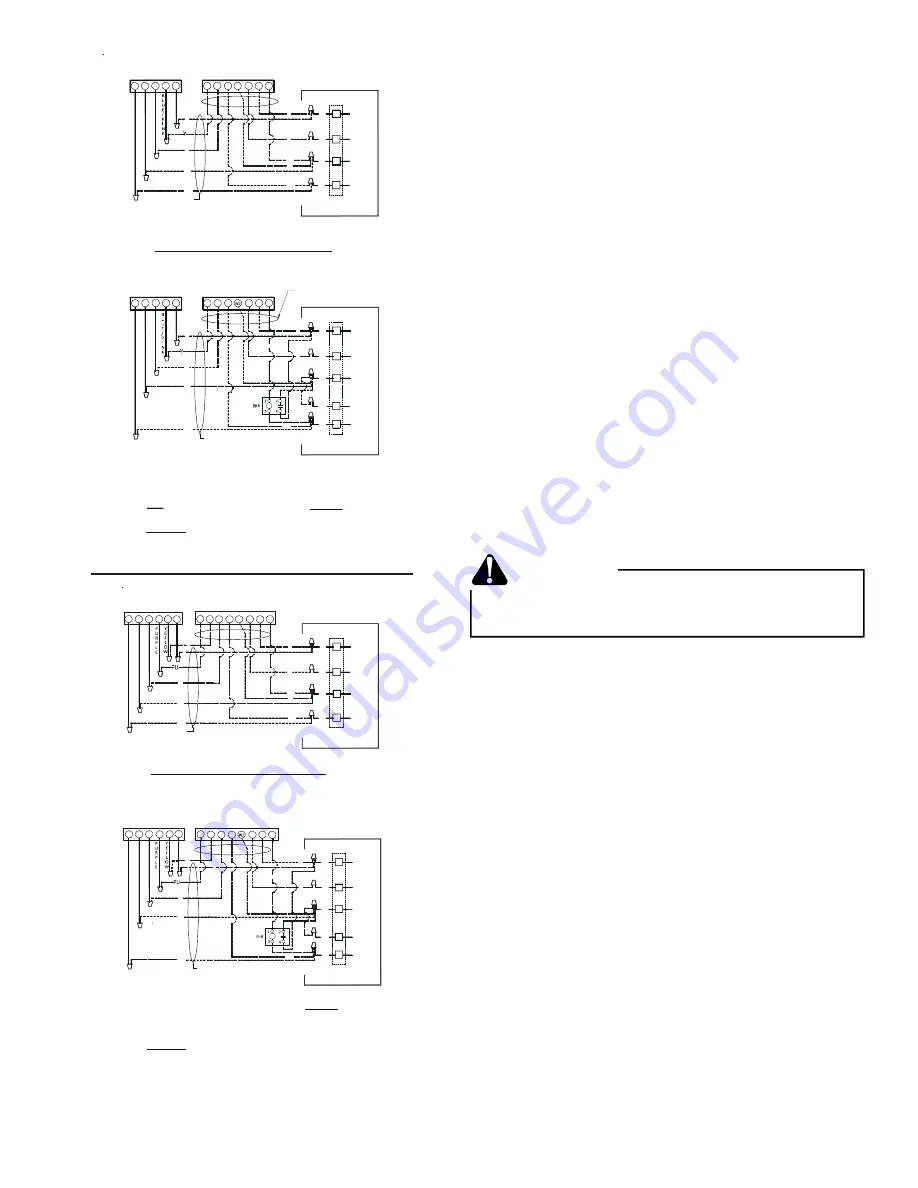

SYSTEM COMPOSITE DIAGRAM - ALL SIZES (EXCEPT 5T 16 SEER) HEAT PUMPS - ABOVE 10 KW

W2

TYPICAL H/P

ROOM THERMOSTAT

HEAT PUMP

R

G

C

W2

RED

GREEN

WHITE

BLUE

INDOOR UNIT

R

O

W

BL

#18 GA. 5 WIRE

R

G

BR

W

BL

R

E

D

O

R

A

N

G

E

W

H

I

T

E

B

L

U

E

BL

W

G

R

C

O

Y

R

Y

O

C

W2

G

R

E

SYSTEM COMPOSITE DIAGRAM - ALL SIZES (EXCEPT 5T 16 SEER) HEAT PUMPS - 10 KW & BELOW

NOTES:

1) TERMINAL BLOCK MARKINGS ARE FOR GOODMAN/AMANA

AIR HANDLERS.

NOMENCLATURE

EHR -EMERGENCY HEAT RELAY (OPTIONAL)

COLOR CODES

BL-- BLUE

BR--BROWN

GR--GREEN

OR--ORANGE

PU--PURPLE

RD--RED

WH-WHITE

Y--YELLOW

BL/PK--BLUE/PINK STRIPE

O

R

A

N

G

E

#18 GA. 5 WIRE

BL

O

W

ROOM THERMOSTAT

HEAT PUMP

B

L

U

E

W

H

I

T

E

W2

C

O

Y

Y

Y2

Y

BL

W

G

C

BLUE

W2

G

WHITE

GREEN

R

INDOOR UNIT

R

RED

W3

BROWN

BR

R

G

BR

BL

O

C

G

R

E

SYSTEM COMPOSITE DIAGRAM - 5T 16 SEER ONLY HEAT PUMPS - ABOVE 10 KW

W2

ROOM THERMOSTAT

HEAT PUMP

R

O

W

BL

#18 GA. 5 WIRE

O

R

A

N

G

E

W

H

I

T

E

B

L

U

E

C

O

Y

R

E

D

R

Y

R

G

C

W2

RED

GREEN

WHITE

BLUE

INDOOR UNIT

R

G

BR

W

BL

BL

W

G

R

O

C

W

G

R

E

SYSTEM COMPOSITE DIAGRAM - 5T 16 SEER ONLY HEAT PUMPS - 10 KW & BELOW

Y2

Y2

Y

R

E

D

R

R

Y2

Thermostat

with Low Voltage Wires to Heat Pump Unit

System Start Up

NOTE:

Units with crankcase heaters should have high

voltage power energized for 24 hours prior to start up.

Heat pumps are equipped with a time/temperature defrost

control with field selectable defrost intervals of 30, 60, or

90 minutes. This setting should be adjusted at this time if

needed. The defrost control also has SmartShift

™

technology, which delays compressor operation at defrost

initiation and termination. If disabling this function is

desired, move the jumper from

“

DLY

”

to

“

NORM

”

on the

defrost control

Adequate refrigerant charge for the matching HSVTC evapora-

tor coil and 15 feet of lineset is supplied with the condensing

unit. If using evaporator coils other than HSVTC coil, it may be

necessary to add or remove refrigerant to attain proper charge.

If line set exceeds 15 feet in length, refrigerant should be added

at .6 ounces per foot of liquid line.

NOTE:

Charge should always be checked using superheat when

using a piston and subcooling when using TXV equipped in-

door coil to verify proper charge.

Open the suction service valve first! If the liquid service valve is

opened first, oil from the compressor may be drawn into the

indoor coil TXV, restricting refrigerant flow and affecting opera-

tion of the system.

POSSIBLE REFRIGERANT LEAK

To avoid a possible refrigerant leak, open the service

valves until the top of the stem is 1/8

”

from the retainer.

CAUTION

When opening valves with retainers, open each valve only until

the top of the stem is 1/8

”

from the retainer. To avoid loss of

refrigerant, DO NOT apply pressure to the retainer. When open-

ing valves without a retainer remove service valve cap and in-

sert a hex wrench into the valve stem and back out the stem

by turning the hex wrench counterclockwise. Open the valve

until it contacts the rolled lip of the valve body.

NOTE:

These are not back-seating valves. It is not necessary

to force the stem tightly against the rolled lip.

After the refrigerant charge has bled into the system, open the

liquid service valve. The service valve cap is the secondary seal

for the valve and must be properly tightened to prevent leaks.

Make sure cap is clean and apply refrigerant oil to threads and

sealing surface on inside of cap. Tighten cap finger-tight and

then tighten additional 1/6 of a turn (1 wrench flat), or to the

following specification, to properly seat the sealing surfaces.

1. 3/8

”

valve to 5 - 10 in-lbs

2. 5/8

”

valve to 5 - 20 in-lbs

3. 3/4

”

valve to 5 - 20 in-lbs

4. 7/8

”

valve to 5 - 20 in-lbs

Do not introduce liquid refrigerant from the cylinder into the

crankcase of the compressor as this may damage the

compressor.