10

calls for heat. At the end of the timing period, the unit’s

defrost cycle will be initiated provided the sensor remains

closed. When the sensor opens (approximately 75° F), the

defrost cycle is terminated and the timing period is reset. If

the defrost cycle is not terminated due to the sensor

temperature, a ten minute override interrupts the unit’s

defrost period.

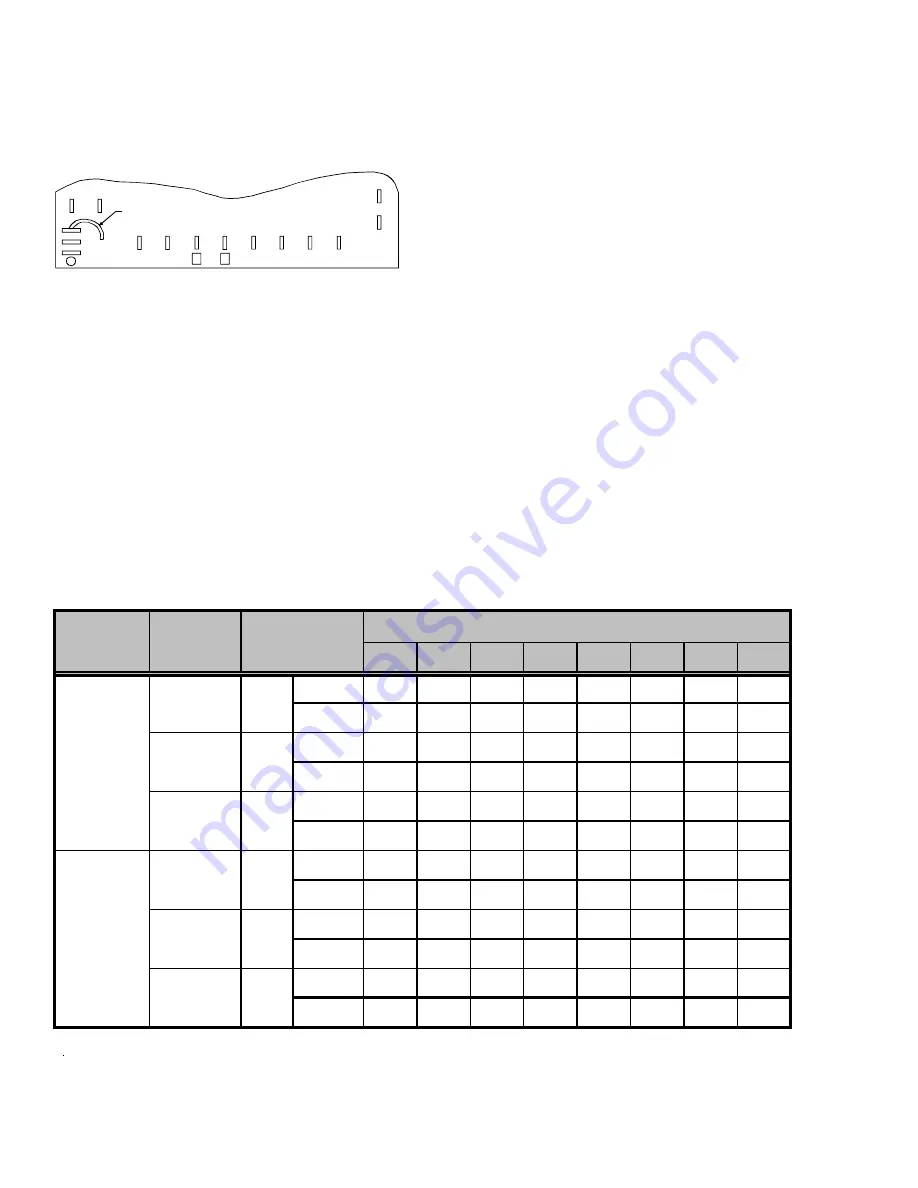

C

Y

W2

R

R DFT

TEST

DF1

DF2

JUMPER WIRE

90

60

30

A

FIGURE 7

SUGGESTED FIELD TESTING/TROUBLE SHOOTING

1.

Run unit in the heating mode (room thermostat calling for

heat).

2.

Check unit for proper charge.

Note: Bands of frost on the

condenser coil indicate low refrigerant charge.

3.

Shut off power to unit.

4.

Disconnect outdoor fan by removing the purple lead from

“DF2” on defrost control.

5.

Restart unit and allow frost to accumulate.

6.

After a few minutes of operation, the unit’s defrost

thermostat should close. To verify this, check for 24 volts

between “DFT” and “C” on board. If the temperature at the

thermostat is less than 28° F and the thermostat is open,

replace the unit’s defrost thermostat, as it is defective.

7.

When the unit’s defrost thermostat has closed, short the

test pins on the defrost board until the reversing valve shifts,

indicating defrost. This should take up to 21 seconds

depending on what timing period the control is set on. After

defrost initiation, the short must instantly be removed or the

unit’s defrost period will only last 2.3 seconds.

8.

After the unit’s defrost thermostat has terminated, check

the defrost thermostat for 24 volts between “DFT” and “C”.

The reading should indicate 0 volts (open sensor).

9.

Shut off power to unit.

10. Replace outdoor fan motor lead to terminal “DF2” on defrost

board and turn on power.

AIR FLOW MEASUREMENT AND ADJUSTMENT

After reviewing section on DUCTING, proceed with airflow

measurements and adjustments. Unit’s blower curves (in

Specification Sheets) are based on external static pressure

(ESP, in. of W.C.). The duct openings on the unit are

considered internal static pressure, so as long as ESP is

maintained, the unit will deliver the proper air up to the

maximum static pressure listed for the CFM required by the

application (i.e. home, building, etc.)

In general 400 CFM per ton of cooling capacity is a rule of

thumb. Some applications depending on the sensible and

latent capacity requirements may need only 350 CFM or up

to 425 CFM per ton. Check condition space load

requirements (from load calculations) and equipment

expanded ratings data to match CFM and capacity.

Notes:

• Data shown is dry coil. Wet coil pressure drop is approximately 0.1" H2O, for two-row indoor coil; 0.2” H2O, for three-row indoor coil; and 0.3” H2O, for four-row indoor coil.

• Data shown does not include filter pressure drop, approx. 0.08” H

2

O.

• ALL MODELS SHOULD RUN NO LESS THAN 350 CFM/TON.

• Reduce airflow by 2% for 208-volt operation.

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

CFM

1,180

1,125

1,075

1,020

955

875

655

-

WATTS

335

325

315

305

295

275

240

-

CFM

1,350

1,280

1,205

1,130

1,050

985

910

845

WATTS

435

420

405

385

375

350

330

310

CFM

1,450

1,370

1,290

1,205

1,130

1,040

960

885

WATTS

495

480

465

440

425

400

385

370

CFM

1,860

1,800

1,745

1,695

1,650

1,600

1,555

1,500

WATTS

410

425

440

455

470

480

495

500

CFM

1,990

1,945

1,885

1,835

1,785

1,740

1,695

1,645

WATTS

510

520

530

545

555

570

585

590

CFM

2,100

2,045

1,985

1,945

1,895

1,850

1,800

1,750

WATTS

595

610

620

630

645

660

670

680

230

230

230

230

230

230

Model

Speed

Volts

E.S.P (In. of H

2

O)

G

P

H

1

3

36H

2

1

*

G

P

C

1

3

36H

2

1

*

LOW

MED

HIGH

G

P

H

1

3

60H

2

1

*

G

P

C

1

3

60H

2

1

*

"T" 1 LOW

"T" 2 MED

"T" 3 HIGH

Содержание GPC 13 SEER H Series

Страница 18: ...18 THIS PAGE LEFT BLANK INTENTIONALLY...

Страница 19: ...19 THIS PAGE LEFT BLANK INTENTIONALLY...