4

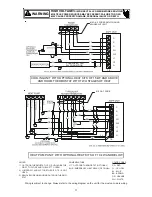

Return Ductwork

DO NOT TERMINATE THE RETURN DUCTWORK IN AN

AREA THAT CAN INTRODUCE TOXIC, OR OBJECTION-

ABLE FUMES/ODORS INTO THE DUCTWORK. The return

ductwork is to be introduced into the air handler bottom (upflow

configuration).

Return Air Filters

Each installation must include a return air filter. This filtering

may be performed at the air handler or externally such as a

return air filter grille. Air handlers mounted in the downflow

orientation, including “B” series, require external filtering. A

washable filter is available as an accessory. To ensure opti-

mum performance frequent filter cleaning is advised. Refer

to

Table 1

for the appropriate filter.

ASPF

Filter Number Qty Required

3137

4260

FIL 48-61

1

1830

FIL 36-42

1

Table 1

Electric Heat

Refer to this manual in combination with the instructions pro-

vided with the heat kit for the correct installation procedure.

The air handlers listed in this manual do not have factory

installed electric heat. Electric heat is available as an acces-

sory. If installing this option, the

ONLY

heat kits that can be

used are the HKR series.

NOTE:

The Amana® brand EHK, ECB, EDB, and EDK kits

are

NOT

approved for use with these air handlers.

The heating mode temperature rise is dependent upon the

system airflow, the supply voltage, and the heat kit size (kW)

selected. Use

Tables 2, 3, and 4

to determine the tempera-

ture rise (

º

F).

3

5

6

8

10

15

20

21

600

18

28

35

41

800

13

21

26

31

42

1000

11

17

21

25

34

50

1200

9

14

18

21

28

42

56

62

1400

8

12

15

18

24

36

48

53

1600

7

10

13

15

21

31

42

46

1800

6

9

12

14

19

28

37

41

2000

5

8

11

12

17

25

34

37

HEAT KIT NOMINAL kW

CFM

Table 2

230/1/60 Supply Voltage - Temperature Rise Table °F

3

5

6

8

10

15

20

21

600

17

27

34

39

800

13

20

25

30

40

1000

10

16

20

24

32

48

1200

8

13

17

20

27

40

53

59

1400

7

11

14

17

23

34

46

51

1600

6

10

13

15

20

30

40

44

1800

6

9

11

13

18

27

36

39

2000

5

8

10

12

16

24

32

35

CFM

HEAT KIT NOMINAL kW

Table 3

220/1/60 Supply Voltage - Temperature Rise Table °F

3

5

6

8

10

15

20

21

600

16

25

32

37

800

12

19

24

38

38

1000

10

15

19

22

30

46

1200

8

13

16

19

25

38

51

56

1400

7

11

14

16

22

33

43

48

1600

6

9

12

14

19

28

38

42

1800

5

8

11

12

17

25

34

37

2000

5

8

10

11

15

23

30

34

CFM

HEAT KIT NOMINAL kW

Table 4

208/1/60 Supply Voltage - Temperature Rise Table °F

NOTE:

For installations not indicated above the following

formula is to be used:

TR = (kW x 3412) x (Voltage Correction) x 1.08 / CFM

Where: TR

= Temperature Rise

kW

= Heater Kit Actual kW

3412

= Btu per kW

Voltage Correction

=.96 (230 Supply Volts)

=.92 (220 Supply Volts)

=.87 (208 Supply Volts)

1.08

= Constant

CFM

= Measured Airflow

NOTE:

The Temperature Rise Tables can also be used to

determine the air handler airflow delivery. When using these

tables for this purpose set the room thermostat to maximum

heat and allow the system to reach steady state conditions.

Insert two thermometers, one in the return air and one in the

supply air. The temperature rise is the supply air temperature

minus the room air temperature.

Use HKR specification sheets to determine the HKR avail-

able for a given air handler.

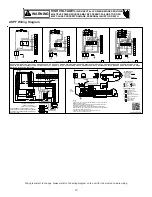

HKR Installation

Follow instructions listed in Installation and Operating Instruc-

tions shipped with the heat kit.

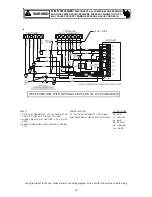

Electrical Supply Wire and MOP

FIRE HAZARD!

To avoid the risk of property damage, personal injury

or fire, use only copper conductors.

Содержание ASPF Series

Страница 14: ...14 THIS PAGE LEFT INTENTIONALLY BLANK...