18

DOK41 HOIAO WxDEN · FD 9912

www.gdts.one

English

Air-to-water heat pump 4 - 6 kW

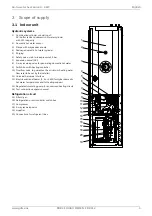

Step 4: Flanging

Flanging must be carried out as follows with a flanging tool

for R-410A refrigerant as shown in the figure.

Hold the copper pipe steady in a mould with the dimen-

sions shown in the bottom table.

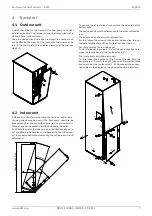

Step 5: Checks

Compare the flanging with the figure on the right.

If the flanging is visibly damaged, cut the relevant section

off and repeat the flanging.

6.7.3 Pipe connections

The pipe connections on the indoor unit and outdoor unit take

place in two steps.

Step 1: Initial fastening

Align the centre of the pipe and tighten the screw nuts by

hand.

Step 2: Fastening

Tighten the screw nuts with a spanner.

Torques

6.7.4 Leak test and evacuation

Air and moisture in the cooling system have unwanted effects

as outlined below.

1) The pressure in the system increases.

2) The operating current increases.

3) The cooling (or heating) output falls.

4) Moisture in the cooling circuit can freeze and block the

capillary tubes.

5) Water can cause corrosion on parts in the cooling

system.

This means that the connection pipes must be checked for

leaks and pumped empty to remove any moisture and non-

condensable gases from the system.

Step 1: Preparation

Ensure that every pipe (liquid and intake side) between the in-

door and outdoor unit is connected correctly. Ensure that both

maintenance valves on the liquid and intake of the indoor unit

are closed at this point.

Step 2: Leakage tightness test

Connect a dry nitrogen gas cylinder (with Schrader) on the

maintenance valve.

Apply 40 bar dry nitrogen to the system. Close the cylinder

valve once the test pressure is reached. The next step is to

search for leaks with leak detection spray.

HINWEIS

ºº

º

ºº

º

NOTE

In order to prevent liquid nitrogen from entering the cooling

system, the top side of the gas cylinder must be higher than

the bottom side when pressure is building in the system.

1) All pipe connections (internal and external) must be

checked for leaks with liquid soap. Bubbles indicate a leak.

The soap must then be wiped away with a clean cloth.

2) If no leaks are found on the system, drain off the nitrogen.

External diameter

"A"

mm

mm

10

1.5 ~ 1.7

15.88

1.6 ~ 1.8

External diameter

Torque

mm

Nm

10

34 - 42

12

65 - 81

Rail

Copper pipe

Clamp

Red arrow marking

Cone

Bracket

Handle

Rail

"A"

Slanting

The inside shines with no scratches

Smooth all round

The same length

all round

Damaged

surface

Cracked

Uneven

thickness

= Incorrect flanging =

Pipework of

the indoor system

Screw nut

Pipework

Torque spanners

Pipework of the indoor system

Open-end spanner (fixed)

Connection pipe

Screw nut

Содержание 041HOIAOW2

Страница 2: ......

Страница 37: ...www gdts one DOK41 HOIAO WxDEN FD 9912 35 Air to water heat pump 4 6 kW English...

Страница 38: ...36 DOK41 HOIAO WxDEN FD 9912 www gdts one English Air to water heat pump 4 6 kW...

Страница 39: ...www gdts one DOK41 HOIAO WxDEN FD 9912 37 Air to water heat pump 4 6 kW English...