Page 22

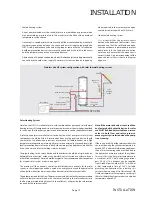

Connections can come loose in transit, and all should be checked before installation.

Ensure that the immersion heater achieves a temperature of at least 60°C in the store

and that the wiring is in accordance with the diagram.

Check the pressure on the air side of the expansion vessel = 3 bar. This must be done

when the water in the cylinder is free to expand in atmospheric pressure or the cylinder

and relevant pipe work is empty.

Check that the drain cock is closed, and open all the cold and hot water taps and other

terminal fi ttings. Allow the system to fi ll with water, and to run until there is no air left

in the system. Close the taps and inspect the system closely for leaks.

Manually open the Relief Valves one by one and check that water is discharged and

run freely through the tundish and out at the discharge point. The pipework should

accept full bore discharge without overfl owing at the tundish, and the valve should

seat satisfactorily.

In line with good plumbing practice, use with excessive fl ux should be avoided.

When soldering above the cylinder, ensure fl ux/solder does not contaminate the

cylinder below, since this can cause corrosion, Flushing should be done performed

as per BS EN 806:4 2010 section 6.2

Allow the cylinder to heat to normal working temperature, then thoroughly fl ush the

domestic hot and cold water pipework through each tap.

NOTE:

If this appliance is to be installed in other than a single domestic dwelling ie. in

an apartment block or student fl ats etc., the hot and cold water system will need to be

disinfected in accordance with BS EB 806:4 2010 section 6.3 and the Water Regulations.

Because the Stainless Lite appliance is stainless steel, the use of chlorine as the

disinfection agent can cause damage unless the appliance is adequately fl ushed

and refi lled with the mains water immediately on completion of the disinfection

procedure. Damage caused through a failure to do this adequately will not be covered

by the warranty.

For the above reasons we recommend the use of a non chlorine dased disinfectant

such as Fernox LP Sterox as manufactured by Cookson Electronics when carrying out

disinfection of systems incorporating these appliances.

Remove the fi lter from the combination inlet group clean and replace. Refi ll the

system and open all hot taps until there is no air in the pipe work.

ENSURE CYLINDER

IS DRAINED PRIOR TO CHECKING OR

REMOVING FILTER FROM THE COMBINATION

INLET GROUP

.

Allow the cylinder to heat to normal working

temperature with whatever heat source is to be

used, and check again for leaks. The Pressure

Relief Valve should not operate during the

heating cycle.

The boiler/heating systems should be fi lled and

commissioned in accordance with good practice

following the guidance in BS 7593:2006/the

boiler manufacturers instructions. This includes

adequately fl ushing the system to remove any

debris that may have been introduced during

installation/maintenance.

NOTE

At the time of commissioning, complete all

relevant sections of the Benchmark Checklist

located on the inside back pages of this

document.

This must be completed during commissioning

and left with the product to meet the Warranty

conditions off ered by Gledhill.

IMPORTANT - DRAIN DOWN PROCEDURE

1 Switch

off both the heat pump and the immersion heater

2 Open the nearest hot tap and run all hot water until cold

3 Close the incoming cold main at the stop tap

4

Hold open the pressure and temperature relief valve until water stops

discharging into the tundish

5 Open all the taps in the property

6 Open the drain cock and immediately hold open the pressure and

temperature relief valve again until the cylinder is empty

INSTALLATION

COMMISSIONING

Содержание Stainless Lite HP Indirect 180-400 litres

Страница 30: ...Page 30 NOTES ...

Страница 31: ...Page 31 NOTES ...