Gilson Company, Inc.

Gilson Binder Ignition System: HM-378

Page 15

WARNING!

ALWAYS disconnect and lockout the electrical

supply to the furnace prior to maintenance or repair.

Diagnostic and repair procedures performed in or

around high-voltage circuits should be conducted

only by a qualified electrician.

Controller Self Test

The Controller will enter a self test mode if the <4> key is

pressed while power is applied to the furnace. This mode

will sequentially test each of the inputs and outputs to

the controller card. Upon entering the self-test mode, the

display will show

FAN and the exhaust fan will be turned

on. No other controller outputs will be turned on except the

fan. This situation will remain until the operator presses

<ENTER> or removes power from the furnace.

Upon pressing <ENTER> the display will show

LOCK

and the fan will be turned off. At this point the output

controlling the door lock will be turned on and the door

latch mechanism can be tested. This situation will remain

until the operator presses <ENTER> or removes power

from the furnace.

Upon pressing <ENTER> the display will show

ALAR and

the alarm output will be turned on. Since this function is

reserved for future use, no visual effect will be noticed.

This situation will remain until the operator presses <EN-

TER> or removes power from the furnace.

Upon pressing <ENTER> the display will alternately display

MAIN and the main chamber temperature. The Lower

red pilot light on the front panel of the switch box will also

be on. If the pilot light is not on, be sure the door is in the

closed position and latched. This activates a switch that

applies power to the main chamber elements only when

the door is closed. Leave the furnace in this condition for

several minutes and note the readings for the main cham-

ber temperature. They should be increasing indicating

the main chamber is getting warmer. If the readings are

decreasing, the thermocouple leads are connected to the

controller card with the wrong polarity. Do not leave the

furnace unattended in this situation, as there is no upper

limit on the main chamber temperature. If left unattended

the elements will burnout due to thermal runaway. The fur-

nace will remain in this situation until the operator presses

<ENTER> or removes power from the furnace.

Upon pressing <ENTER> the display will alternately show

AFT and the temperature in the Afterburner chamber.

Leave the furnace in this condition for several minutes

and note the readings for the Afterburner chamber

temperature. They should be increasing indicating the

Afterburner chamber is getting warmer. If the readings

are decreasing, the thermocouple leads are connected

to the controller card with the wrong polarity. Do not leave

the furnace unattended in this situation as there is no

upper limit on the after burner chamber temperature. If

left unattended the elements will burnout due to thermal

runaway. The furnace will remain in this situation until

the operator presses <ENTER> or removes power from

the furnace.

Upon pressing <ENTER> the display will alternately

display

IdLE and the temperature of the main chamber.

At this time the furnace is ready to run and is out of the

self test mode.

Problem #1: Controller Display does Not Turn On

Probable Causes:

1. Tripped circuit breaker or blown fuse; furnace unplugged.

2. Blown furnace switch box fuse.

3. Defective transformer.

4. Defective controller board.

5. Disconnected wire in switch box.

Check circuit breakers or fuses for the wall outlet. Then,

remove the furnace fuse and check it by placing the leads

of an ohmmeter on the ends of the fuse. If the ohmmeter

reading is 0 ohms, the fuse is okay. If the reading is infinity

or no needle movement, the fuse is bad. Replace a bad

fuse with a SS2-250mA, 250VAC fuse.

Next, check the controller board with a voltmeter. Make

sure the furnace is unplugged. Remove the four screws

holding the controller board faceplate to the switch box.

Lift faceplate out of box and let the board hang on the box

with the back of the board facing you. Plug the furnace

back in. Touch the voltmeter probes, in AV Volt mode, to

connectors with the orange and white wires. Make sure the

voltmeter is in the AC mode when placing the probes on

these connectors. If you find voltage (approximately 20V

AC) present, that means current is reaching the board from

the transformer, so the board is probably defective.

If there is no voltage, the transformer is probably defec-

tive. But before replacing the transformer,

disconnect

and lockout the power supply. Remove the switch box

and look for both a disconnected wire between the cord

set and transformer and between the transformer and

the controller board.

11.0 THE TEMPERATURE CONTROLLER - TROUBLESHOOTING

Содержание HM-378

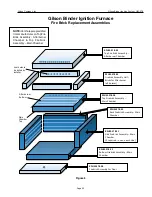

Страница 18: ...Gilson Company Inc Gilson Binder Ignition System HM 378 Page 18 Figure 1 Parts Accessories Diagram ...

Страница 19: ...Gilson Company Inc Gilson Binder Ignition System HM 378 Page 19 Control Panel Figure 2 ...

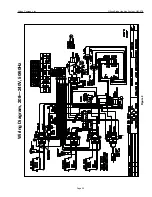

Страница 20: ...Gilson Company Inc Gilson Binder Ignition System HM 378 Page 20 Figure 3 Wiring Diagram 208 240V 50 60Hz ...