10/32

03.06.20, Subject to alterations

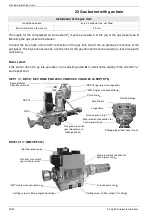

Gas pressure monitor

15 Gas pressure monitor

15.1 Gas pressure switch min.

The

gas pressure switch MIN

at the gas fitting ser-

ves to monitor the gas inlet pressure. If the minimum

gas inlet pressure is not reached (factory setting), the

burner is switched off. The burner automatically

starts again when the minimum pressure is excee-

ded. The gas pressure monitor as

density control

DK

generally serves to check the valves and must be

set to 50% of the static gas inlet pressure.

The monitoring of the gas inlet pressure and the

tightness control are either carried out only with the

gas pressure monitor DK

(the jumper GDW MIN

must not be removed)

or with the gas pressure

switch MIN and the gas pressure switch DK

(the

GDW MIN jumper has to be replaced with the

connection of the gas pressure switch MIN)

.

When using the gas cycle MB-VEF 412, the connec-

tion is made via the 7-pin connector and is only

evaluated as DK MIN. The plug bridge must not be

removed

Additional parameterization of the LMV is not re-

quired here.

15.2 Gas pressure monitor max.

Optionally a gas pressure switch max. can be incorporated.

The LMV and the wiring have been prepared such that only the jumper in the socket part (brown) at the

burner needs to be removed. In addition, the male connector and the gas pressure switch max. must be

wired in accordance with the circuit diagram. If the gas pressure switch max. has tripped, a fault is shown

in the display (AZL).

First, the gas pressure switch max. must be unlocked; to do this the lid of the gas pressure switch max.

must be unscrewed and the red button pressed.

Then, the fault in the display can be deleted (press the

i/reset

button for 3 sec.).