20/32

03.06.20, Subject to alterations

Gas burner with gas train

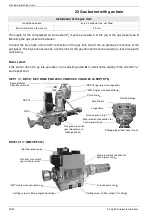

22 Gas burner with gas train

The nipple for the compressed air connection P

L

must be screwed in at the top of the gas jacket (see 9.

Mounting the gas jacket at the boiler).

Connect the blue hose at the "AIR" connection of the gas train and at the air pressure connection at the

gas jacket. The blue hose serves as a control line for the gas train and must be routed in a loose loop with-

out kinking.

Burner start:

If the burner does not go into operation, turn adjusting screw

N

or small flame slightly in the direction "

+

"

and repeat start.

KEV 1 ½", KEV2", KEV DN65 (VGD20.40, VGD20.50, VGD40.65 all SKP15/75)

.

KEV412 1 ½"(MB-VEF 412)

Installation of the gas train

Installation position

only in horizontal line, not tilted.

Minimum distance to masonry

20 mm

SKP 15

VGD

Pulse line p

G

SKP 75 (gas pressure regulator)

Cover plate for

"AIR" air pressure connection p

L

Adjustment screws

Detailed image

Large flame

Small flame

Furnace pressure p

F

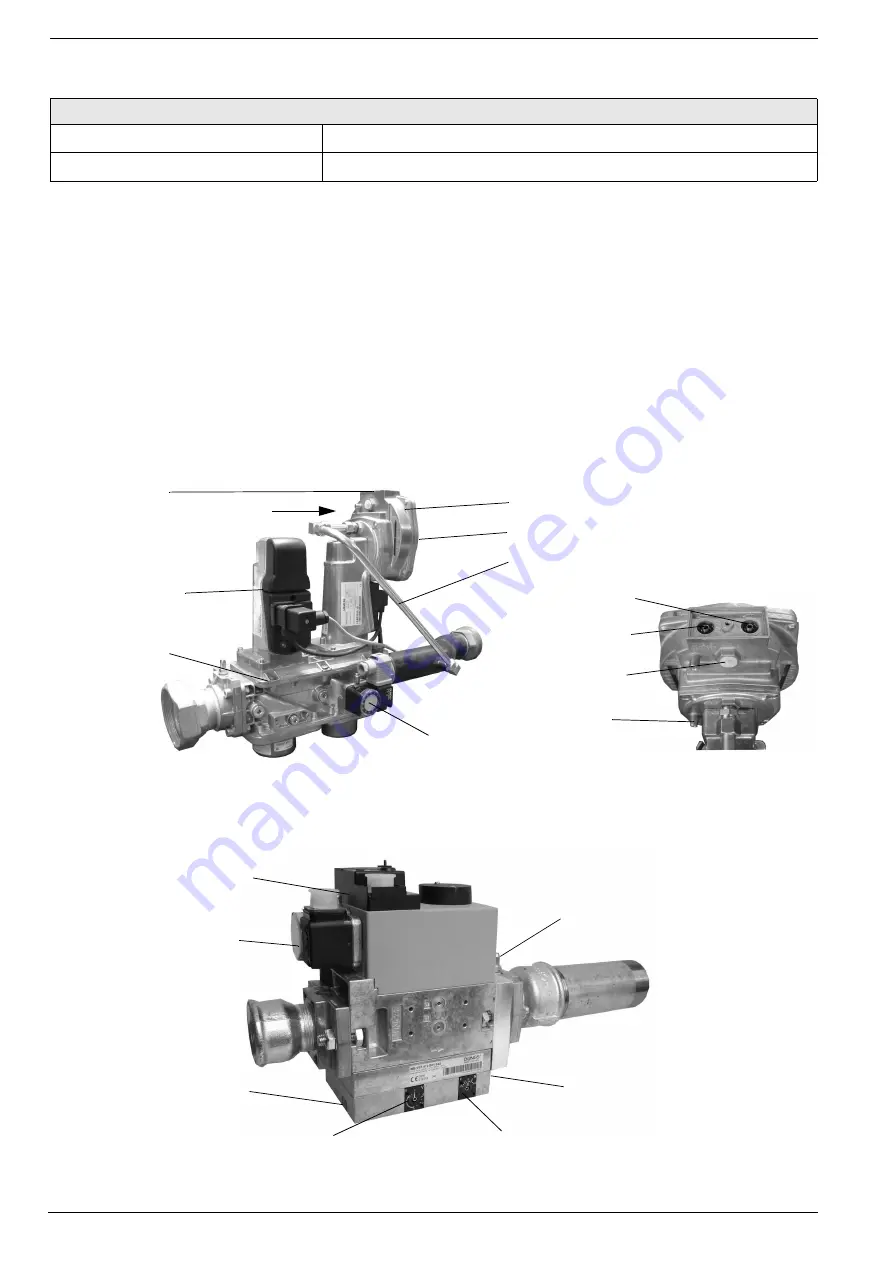

Photograph without cover sheet

Gas pressure switch

(gas inlet pressure

leakage check)

Measurement connection for

nozzle pressure p

G

"AIR" air pressure connection p

L

Furnace pressure p

F

Gas pressure switch

(gas inlet pressure)

Measurement connection for

nozzle pressure p

G

Inlet flow pressure p

e

Setting screw N (Min. output 1st setting)

Setting screw V (Max. output 2nd setting)