COMPACT 50M-230 · TOTEM 50M-230 INSTRUCTION MANUAL

2

Otherwise the high temperature of the sun makes possible that an overpressure is created by the expansion due to the diesel and/or petrol dilation that

there is in the tubes, which could cause a retainer and mechanic element breaking of the pump and/or the meter.

3.5. RECOMMENDATION: To avoid possible retainer breaking, it is advisable to install a check valve between the 90º elbow placed in supply kit outlet

and the delivery hose. So, the retainer breakings because of the thermal expansion or an accidental delivery hose footfall are avoided.

ATTENTION: Make sure that the check valve is placed in the correct direction. The arrow must indicate the flow direction.

3.6. Whenever there is a fuel leak, please clean it immediately to avoid a possible ignition or explosion or personal injuries.

3.7. If the supply kit remains without operating in a place exposed to freezing temperatures or ice, it is necessary to empty the hoses and the pump body.

In the same way, it is advisable to make this operation if the supply kit is without operating during a long time (even though the temperature is normal).

3.8. ATTENTION

The kit must not be turned on before finishing the installation. It is strictly forbidden to put fingers or other parts of the body inside the holes.

Before starting the dismantling or assembly of the supply kit, switch it off to avoid accidental ignitions or electrical discharges.

4. INSTALLATION

The systems must be designed to work with a minimum suction height.

The equivalent maximum suction height is 4.5 m for diesel. (This equivalence is the vertical distance from the bottom of the suction tube to the inlet tube of

the supply kit plus the wastages by friction in the vertical and horizontal route of the tube, the elbows etc). It is necessary to install a retention valve of 1” –

1 1/4” suitable for diesel. The top drop levels will affect the flow, cause the pump-accelerated fatigue, and the possibility of “cavitation” will drastically

increase.

All the supply kits can be installed on aerial or buried tanks.

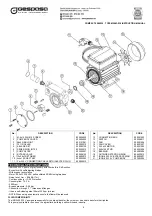

TOTEM FIXATION DRAWING

4.1. General

Before assembling the supply kit, please check there are the following elements in the installation:

- Flexible hose to join the suction group with the suction pipe

- Cable according to the current regulation with 2x2.5 mm² + T mechanical protection

- Enough space: A service station must be placed in a wide space to allow the vehicle movement.

You have to take into account the space exigencies, both for the assembly and its maintenance.

TOTEM KIT FIXATION:

The TOTEM must be fixed by 4 point with M8 screws with its own washers. Please see the drawing.

COMPACT/MSGM KIT FIXATION:

The COMPACT must be fixed in a pedestal or wall support with M6 screws. The hole placing

depends on each model.

4.2. Buried tank

The tank must be at a depth of 60 cm from the ground level to hold the suction elevation at the

minimum.

4.3. Base

Install a concrete base with enough space for the suction tube and the electrical cables.

4.4. Suction tube

Use a tube on the suction line, in accordance with the regulation, with suitable elbows and couplings,

forming articulated joints over the tank or below the supply kit to prevent the tank settlement from

freezing.

ATENCIÓN:

Remove the suction hole plug of the hydraulic group before connecting the flexible tube.

The horizontal suction line must be 45 cm below, and, if it is possible, it must have a continuous drop to the tank of 1-2 %.

In the suction tube of the supply kit you must assemble an angle valve if it is a buried tank, or an anti-siphon valve in the event of the aerial tanks.

4.5. Ventilation tank tube

Use the tube to allow the tank ventilation in accordance with the regulation. The joints must be articulated, and the tube must stick out a minimum of 0.5 m

over the ground level. On its top it must have the protection against the rain. In the event of tanks with a capacity lower than 10,000 litres, you can use a 1

1/2” tube.

The horizontal tube sections must have a light drop to the tank.

4.6. Electric installation

IT IS OBLIGATORY TO INSTALL A MOTOR PROTECTION DEVICE FOR THE EQUIPMENT WARRANTY ACCORDING TO THE

EN 60947 RULE, SUITABLE FOR THE SUPPLY KIT POWER AND CONSUMPTION.

Precaution:

A qualified electrician, who knows the right electrical codes and regulations at local level, must do the cables and the electrical installation.

The supply kit must be adequately earthen and use suitable tubes and cables.

Warning:

The above given information is to help the installer. It is on a general sense so that it can include a wide range of applications. This information

is the result of many working years, and it can be considered like exact and trustworthy. However, TOT COMERCIAL SA does not assume the

responsibility derived from its use.

5. CALIBRATION AND OPERATION INSTRUCTIONS

Please read the enclosed meter or controller operation manuals for its calibration and operation. To get the best results, the supply kit must be installed

according to that described in this INSTALLATION section. For its initial starting, please let the nozzle open during some seconds. Then the pump will be

primed.

6. MAINTENANCE

ATTENTION

Check the hose and the nozzle to see whether these are worn or damaged. The hoses or nozzles in bad state can be a potential

risk of insecurity and/or attempt against the environment.