COMPACT 50M-230 · TOTEM 50M-230 INSTRUCTION MANUAL

7

The meter is given with a horizontal inlet and outlet. Nevertheless, the user can change their position in a short time, the plugs of the desired direction

must be taken out and put them on the non-desired direction. The inner threads have joints that guarantee the sealing; you must only tighten them till its

locking, giving up pastes, liquids, and sealing products.

The MG-80 meters are for private use. The MG-80 Volumetric Mechanical Meters has two numeration types:

- Partial with three big numbers where you can read up to 999 litres. It can be reset through a lateral wheel after each transfer.

- 6-digit totalizer with capacity of 999.999 litres; after that and with its operation, it is automatically reset, starting the program again.

2. CALIBRATION

The meters are precalibrated in the factory. IT IS ADVISABLE TO MAKE A CALIBRATION ONCE IT IS INSTALLED. Each liquid type has its own density

and viscosity. To achieve a trustworthy measurement, it is advisable that the recalibration is done with a homologated test tube or dekalitre. It can be used

a container from which we have to know its capacity.

Calibration procedure

2.1. For an exact calibration, the meter, the hose, the nozzle and the pump must be full of liquid and free of air. This is achieved emptying from 10 to 20

litres of liquid and closing the nozzle, without stopping the pump until the operation is finished.

2.2. Fill the homologated dekalitre recipient until the exact measurement (10 or 20 litres).The bigger the recipient is, the better calibration accuracy you

have.

The calibration process must be done with the nozzle totally open. Never calibrate it with the nozzle half opened.

2.3. If the quantity does not correspond with the emptied liquid on the recipient, it needs to be calibrated.

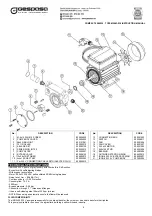

2.4. To make this operation, take out the plug (4) and turn the screw (6) clockwise. Then the flow percentage decreases. If you turn it anticlockwise, it

increases. A complete turn varies the measurement more or less in 0,4 litres, per each 10 litres.

2.5. If we want to guarantee a correct calibration, we have to repeat it three or four times. If the result is correct, a good adjustment will be achieved and

the meter will be ready to work. Do not exceed 3.5 bar pressure, and do not work less than 1 bar.

2.6. The MG-80 meter can work by gravity or with pump. Remember that the suitable minimum pressure is 1 bar with a minimum flow of 15 l/min, and with

an accuracy of ±1 %. If you decide to use it by gravity, it can give errors on the measurement due to the different liquid heights in the tank. We recommend

you to always install a pump.

3. PROBLEM GUIDE

BREAKDOWN POSSIBLE

CAUSE

SOLUTION

Litres are passing but the numeration does

not count.

- there are impurities on the measuring

chamber.

- clean the measuring chamber (10).

Loss of liquid

- Allen screws loose

- because of the overpressure the joint has

been moved.

- joint breaking

- tighten up Allen screws (15).

- replace joint (9 or 13).

- replace joint (9 or 13).

The total or partial numeration does not

point correctly.

- numeration breaking

- replace numeration (22).

You read more or less litres than those

supplied.

- calibration failure

- the minimum flow is not respected.

- calibrate the meter according to the section 2.

- the minimum supply flow has to be 20 l/min to guarantee

a trustworthy measurement.

Low flow rate

- impurities on the measuring chamber

- dirtiness on the red adaptor

- clean the measuring chamber (10).

- clean the inner sieve.

It counts too quick or too slow.

- bad calibration

- air inlet

- blocked gears

- the minimum flow is not respected.

- calibrate the meter according to the section 2.

- look for and repair the possible losses or air inlets on the

system.

- clean and replace the gears (23, 26, 27 or 33).

- the minimum supply flow has to be 20 l/min to guarantee

a trustworthy measurement.