8

NOTE!

See chapter 8.3 for required

quantity of water and water

pressure.

In the case of poor water quality

(sand, etc.), we recommend

that a fi ne water fi lter is fi tted in

the water inlet.

4.1.3 Fuelling

WARNING!

Always shut off the engine

and let it cool for at least two

minutes before fuelling.

Avoid spilling fuel.

If you do spill fuel when fuelling,

do not start the engine before

the spilled fuel has evaporated.

If the washer is on a trailer, any

fuel spills must be wiped up

before the machine is started.

Never expose the machine

to an open fl ame. Smoking is

prohibited during fuelling. Also

read the operating manual for

the fuel engine.

Note:

Never operate the

ma chine in a closed room; the

exhaust fumes are dan ger ous.

Follow the safety instructions

in chapter 1!

4.2

Start the washer

4.2.1 Switching on the

washer when it is

connected to a water

supply

1. Start the engine. (See the

operating manual for the fuel

engine.)

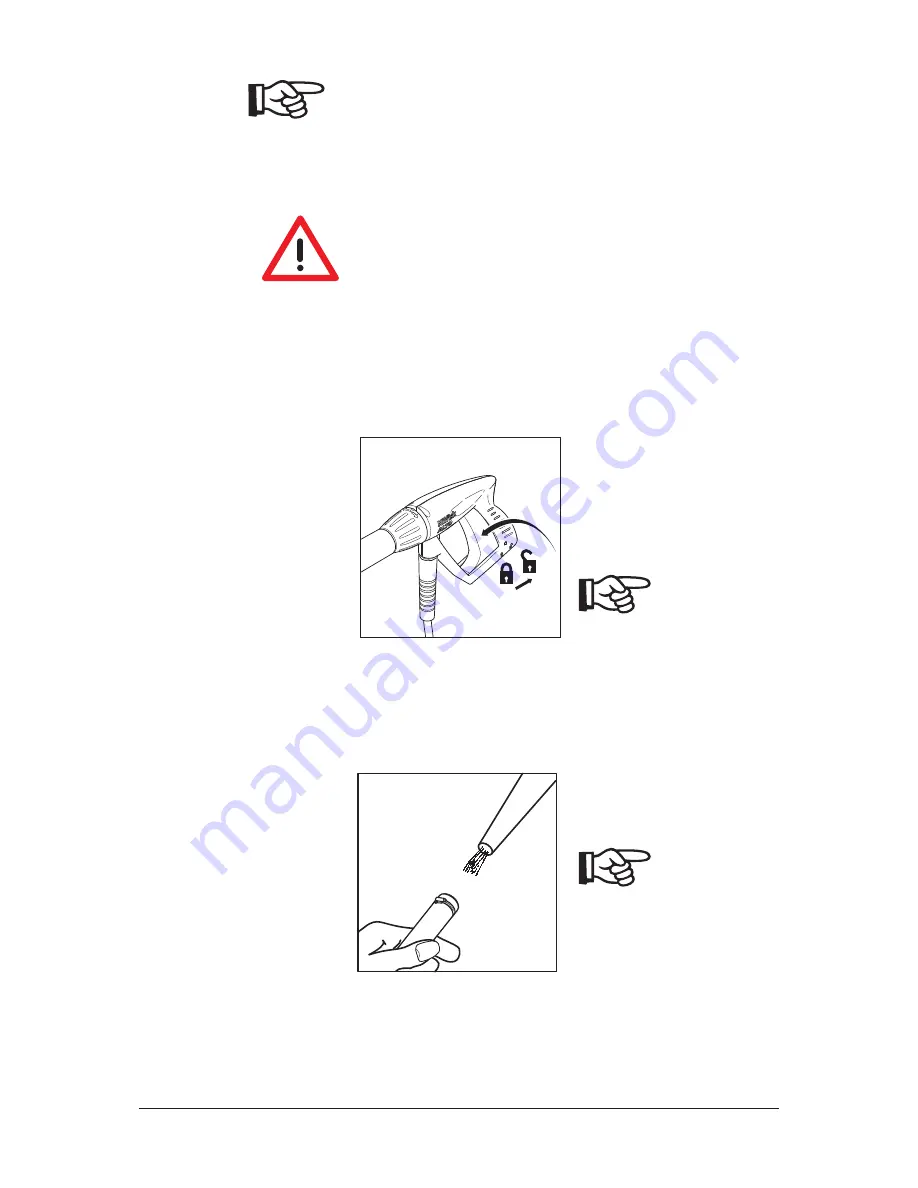

2. Unlock the spray gun and

operate it.

3. Lock the safety catch even

during short pauses.

NOTE!

Operate the

spray gun several

times at short intervals to vent

the system.

4.2.2 Switching on the

washer when it is

connected to open

tanks (suction mode)

1. Before connecting the suction

hose to the washer, fi ll the

hose with water.

2. Start the washer.

3. Unlock the spray gun and

activate it.

4. When using this machine in

suction mode, fi rst ensure

that the system has been

bled of air by letting the

machine run without spray

lance mounted until all air

has escaped.

During work breaks of more

than three minutes, switch off

the washer.

NOTE!

For automatic

suction from a tank,

watercourse or similar sup ply,

the inlet hose must be fi lled

with water before you start.

The suction height depends on

the water temperature. Max.

suction height (see section 8.3

Technical Data) is reached with

cold water (up to 8°C). With

70°C/60°C warm water, the

ma chine must be under or at

the water level.

(continued -->)