8

ENGLISH

2.2. PRELIMINARY CHECKS

To ensure a correctly operating automated system, the structure

of the existing gate or gate to be built must satisfy the following

requirements:

The construction elements of the gate must comply with the

provisions of the EN12604 and EN 12605 standards.

Leaf dimensions must not exceed the values indicated in pa-

ragraph 1.1.

The travel limit mechanical stops, for both opening and closing,

must be installed.

The structure of the leaves must be sufficiently rigid and sturdy,

suitable for the automated system.

Leaf movement must be smooth and free of any jamming during

the entire travel.

Adequately sturdy hinges, in good condition

Check the possibility of fastening the operator, respecting the

installation dimensions – see paragraph 2.3.

Check if an efficient earth plate is present for electrical connec-

tion to the operator.

Do not use the operator to move safety exits or gates installed

on emergency routes (see escape routes).

If a pedestrians door is built into the leaf due to be motorised,

you must add a safety switch on the door, connected to

the stop input, in order to prevent the automated system

working while the door is open.

The condition of the gate structure directly influences the safety

and reliability of the automated system.

We advise you to carry out the metalwork jobs if any, before

installing the operator.

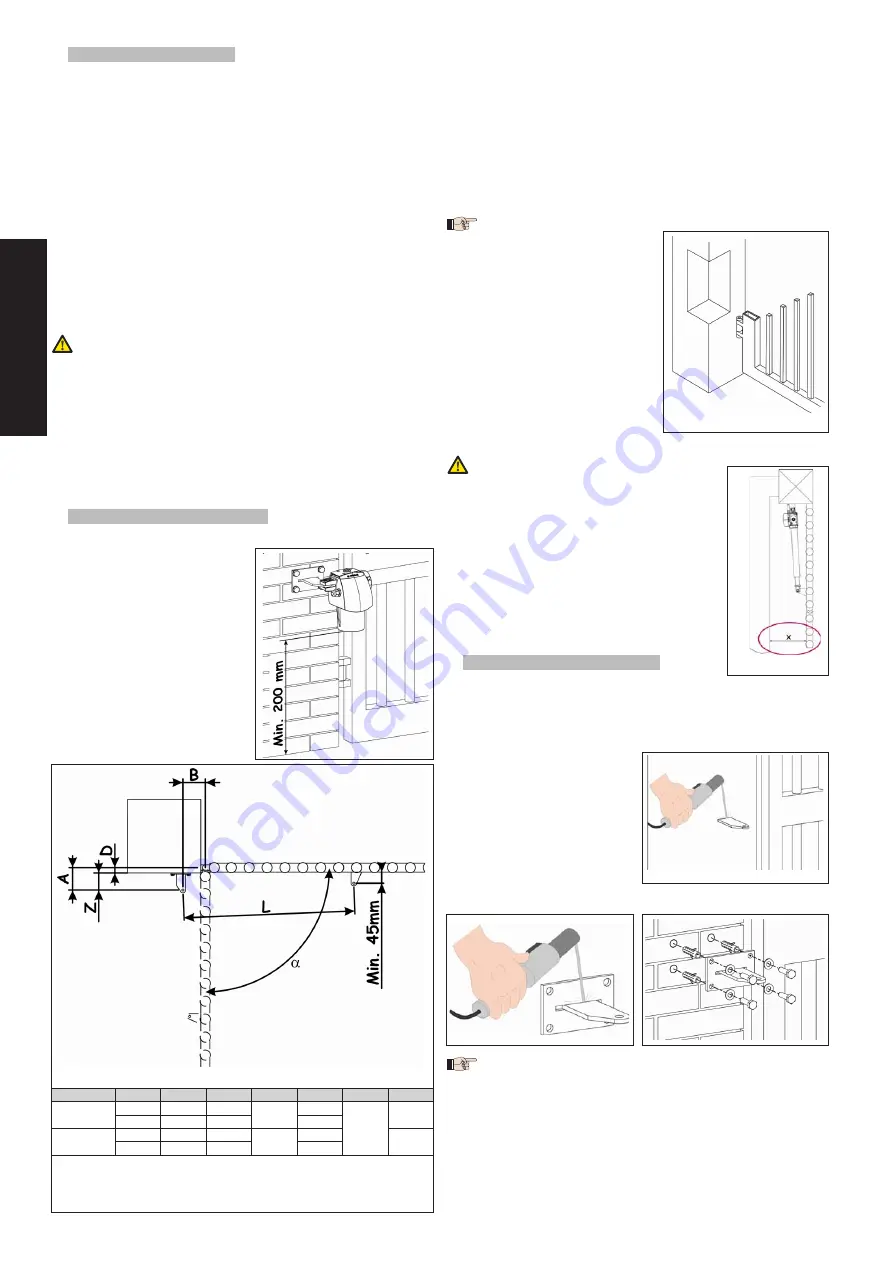

2.3. INSTALLATION DIMENSIONS

Determine the installation position of the operator by referring to

figure 4, where the minimum off-

ground height is specified.

To determine the operator instal-

lation dimensions, consult figure 5

and the relevant table.

Fig. 5

Version

a

A

B

C

a

D

b

Z

c

L

300

90°

145

145

300

100

45

930

110°

125

125

80

400

90°

195

195

400

150

1110

110°

165

165

120

a

Useful rod stroke

b

maximum dimension

c

minimum dimension

•

•

•

•

•

•

•

•

2.3.1. g

eneRal

Rules

foR

deteRmining

the

installation

dimensions

.

To obtain

90°

opening of the leaf:

A+B=C

.

To obtain leaf opening

greater than 90°: A+B<C

.

Lower dimensions

A

and

B

cause greater leaf peripheral

speed.

Limit the difference between dimension

A

and dimension

B

within 4 centimetres; higher differences cause considerable

leaf peripheral speed variations during closing and opening

movements.

Maintain a

Z

dimension ensuring that the operator does not

impact the pilaster, while the leaf is closed.

If the dimensions of the pilaster or the position of the hinge

do not allow the operator to

be installed, to respect the

determined dimension

A

, a

niche must be created on the

pilaster as shown in figure 6.

The dimensions of the niche

must allow smooth installation

of the motor, not limit motor

rotation and not obstruct mo-

tor release operations.

When the operator has been installed, check if dimension “X”

in Fig. 7 is at the minimum of 500 mm. If

dimension “X” is less than 500 mm, run an

impact test on the point indicated in Fig.7,

as described in standard UNI EN 2445,

and make sure that the measured values

conform to the specifications of standard

UNI EN 2453.

If the thrust values are not within the values

specified in standard UNI EN 2453, the

zone indicated in figure 7 MUST BE pro-

tected with a protective device confor-

ming to the UNI EN 2978 standard.

2.4. INSTALLING THE OPERATOR

Fit the rear bracket in the position you have

just determined. If necessary, the length of the rear bracket

can be modified in order to respect the installation dimensions

(Z dimension included).

For iron pilasters, weld the bracket directly on the pilaster (Fig.

8).

For masonry pilasters, an ap-

propriate plate (available

as a optional item) must be

used for scew fastening.

Weld the rear bracket to

the plate and screw it

on, inserting it in the slot

(Fig. 9).

Secure all the items on the

pilaster using adequate securing systems (Fig. 10).

Fig. 9

Fig. 10

During the operations to secure the rear bracket, use a level

to check if the bracket is perfectly horizontal.

1.

2.

3.

4.

5.

1.

a–

b–

i–

ii–

Fig. 4

Fig. 4

Fig. 6

Fig. 6

Fig. 7

Fig. 7

Fig. 8

Fig. 8

Содержание G-BAT

Страница 1: ...g bat ENV...

Страница 28: ...NOTE NOTES NOTE NOTAS ANMERKUNG OPMERKINGEN...

Страница 29: ...NOTE NOTES NOTE NOTAS ANMERKUNG OPMERKINGEN...

Страница 45: ...NOTE NOTES NOTE NOTAS ANMERKUNG OPMERKINGEN...

Страница 46: ...NOTE NOTES NOTE NOTAS ANMERKUNG OPMERKINGEN...