Air Handler

21

Notes:

4)90 second off delay when "G"

is de-energized.

5)Jumper "R" and "o" together if working

with cooling only condensing unit.

HEAT STRIP-4

LS1-4

HS-2

CB2

CB2

HEAT STRIP-3

LS1-3

HS-2

HEAT STRIP-2

LS1-2

HS-1

HEAT STRIP-1

LS1-1

HS-1

CB1

CB1

HS-1

HS-2

LS2-4

LS2-3

LS2-2

LS2-1

45

50

47

44

41

51

48

45

42

52

49

46

43

20kW HEAT KIT

15kW HEAT KIT

SEE NOTE 2

19

RD

20

WH

21

RD

22

RD

23

RD

24RD

RD

10kW HEAT KIT

5KW HEAT KIT

CB2

CB2

HEAT STRIP-3

LS1-3

HS-2

HEAT STRIP-2

LS1-2

HS-1

HEAT STRIP-1

LS1-1

HS-1

CB1

CB1

HS-1

HS-2

LS2-3

LS2-2

LS2-1

45

47

44

41

48

45

42

49

46

43

SEE NOTE 2

RD

HEAT STRIP-2

LS1-2

HS-1

HEAT STRIP-1

LS1-1

HS-1

CB1

CB1

HS-1

LS2-2

LS2-1

44

41

45

42

46

43

SEE NOTE 2

HEAT STRIP-1

LS1-1

HS-1

CB1

CB1

HS-1

LS2-1

41

42

43

SEE NOTE 2

19

RD

20

WH

21

RD

22

RD

23

RD

24RD

19

RD

20

WH

21

RD

22

RD

24RD

19

RD

20

WH

21

RD

22

RD

24RD

XFMR

YE

WH

MAIN BOARD

SEE NOTE 1

SEE NOTE 4

X10

X3(C)

G_SCAN

13

RD

BK

BU

X7(N)

X13(L)

X2

BLOWER

MOTOR

X14

X6

E

WH

15

17

WH

16

91

RD

81

BN

BK BU

SEE NOTE 5

1RD

2WH

X1

X2

(AC-N) (AC-L)

X11

FU1

14RD

4RD

5RD

6RD

8WH

3RD

7RD

X8

FU2

1

XT2

SEE NOTE 3

X2

(AC-N)

3)Remove the blue lead from "X7"

terminal on the main board and

then connect the black lead to

"X7" terminal for 230 volts,

tape seal the unused blue lead.

9RD

10RD 11RD

12RD

1 3

4 5 6

2

1 3

4 5 6

2

BK BU

RD

BN

1)For Air Handler without installing

Electric Heater,connect the supply

power to"L1"and"L2"terminal block.

X1

XT3

G

POWER

XT1

L1

L2

RD

GROUND

BK

BK

BK

BK

L2

L1

RD

RD

RD

35

33

31

GROUND

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

34

36

32

3

1

4

3

2

1

6

5

4

3

2

1

L2

L1

X1

RD

RD

RD

RD

35

33

31

GROUND

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

38

34

36

32

37

4

3

2

1

4

3

2

1

6

5

4

3

2

1

L2

L1

X1

LEGEND

CB-CIRCUIT BREAKER

HS-HEAT SEQUENCER

LS1- TEMPERATURE LIMIT SWITCH

LS2- THERMAL FUSE

XFMR-TRANSFORMER

X1

,X

2-Q U IC

K

C O N N E C T IO N

P

LU G

C-FAN CAPACITOR

XT1/XT2/XT3 TERMINAL BLOCK

FACTORY WIRING:

FIELD WIRING:

3

6

5

4

2

1

C

GROUND

YEGN

M

YEGN

GROUND

RD

31

GROUND

BK

BK

BK

BK

32

3

1

6

5

4

3

2

1

L2

L1

X1

RD

33

31

BK

BK

BK

BK

34

32

4

3

2

1

6

5

4

3

2

1

X1

2)For Air Handler with Electric Heater,

connect the supply power to circuit

breaker.If you ordered the Heat kit

without circuit breaker,connect the

supply power to the stripped black

and red wires.

O

C

W2

W1

R

O_SCAN

X9

X4(R)

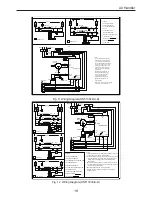

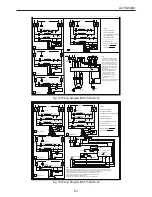

Fig. 15 Wiring Diagram(HNF13048/A-D)

1)For Air Handler without installing Electric Heater,connect the supply power to"L1"and"L2"terminal block

2)For Air Handler with Electric Heater,connect the supply power to circuit Breaker.If you ordered the Heat kit

without circuit breaker,connect the supply power to the stripped black and red wires.

3)Remove the blue lead from "X7" terminal on the main board and then connect

the black lead to "X7" terminal for 230 volts,tape seal the unused blue lead.

XFMR

RD

BK

YE

WH

1

BU

1RD

2WH

4RD

5RD

6RD

9RD 10RD 11RD

MAIN BOARD

7RD

8WH

SEE NOTE 3

Notes:

12RD

SEE NOTE 4

SEE NOTE 5

X10

X3(C)

X7

G_SCAN

HEAT STRIP-4

LS1-4

HS-2

CB2

CB2

HEAT STRIP-3

LS1-3

HS-2

HEAT STRIP-2

LS1-2

HS-1

HEAT STRIP-1

LS1-1

HS-1

CB1

CB1

HS-1

HS-2

LS2-4

LS2-3

LS2-2

LS2-1

50

47

44

41

51

48

45

42

52

49

46

43

20kW HEAT KIT

15kW HEAT KIT

SEE NOTE 2

19RD 20WH 21RD 22RD 23RD 24RD

45RD

10kW HEAT KIT

5KW HEAT KIT

HEAT STRIP-3

LS1-3

HS-2

HEAT STRIP-2

LS1-2

HS-1

HEAT STRIP-1

LS1-1

HS-1

HS-1

HS-2

LS2-3

LS2-2

LS2-1

47

44

41

48

45

42

49

46

43

SEE NOTE 2

19RD 20WH 21RD 22RD 23RD 24RD

45RD

HEAT STRIP-2

LS1-2

HS-1

HEAT STRIP-1

LS1-1

HS-1

HS-1

LS2-2

LS2-1

44

41

45

42

46

43

SEE NOTE 2

19RD 20WH 21RD 22RD

24RD

HEAT STRIP-1

LS1-1

HS-1

HS-1

LS2-1

41

42

43

SEE NOTE 2

19RD 20WH 21RD 22RD

24RD

X13

AC-L(X1)

AC-N(X2)

RD

BK

CN1

AC-N(X2)

SEE NOTE 1

LEGEND

CB-CIRCUIT BREAKER

HS-HEAT SEQUENCER

LS1- TEMPERATURE LIMIT SWITCH

LS2- THERMAL FUSE

XFMR-TRANSFORMER

X1-QUICK CONNECTION PLUG

C-FAN CAPACITOR

XT1/XT2/XT3 TERMINAL BLOCK

FACTORY WIRING:

FIELD WIRING:

X1

POWER

13YEGN

GROUND

L2

L1

M

3

YEGN

GROUND

RD

31

GROUND

BK

BK

BK

BK

32

3

1

6

5

4

3

2

1

L2

L1

X1

RD

RD

33

31

GROUND

BK

BK

BK

BK

BK

BK

BK

BK

34

32

4

3

2

1

6

5

4

3

2

1

L2

L1

X1

RD

RD

RD

35

33

31

GROUND

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

34

36

32

3

1

4

3

2

1

6

5

4

3

2

1

L2

L1

X1

RD

RD

RD

RD

35

33

31

GROUND

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

38

34

36

32

37

4

3

2

1

4

3

2

1

6

5

4

3

2

1

L2

L1

X1

5)Jumper "R" and "o" together if working with cooling only condensing unit

4)90 second off delay when "G" is de-energized.

O_SCAN

O

X9

X4(R)

XT3

XT2

6

5

4

2

1

C

W2

W1

G

R

CB2

CB1

CB2 CB1

CB1

CB1

CB1

CB1

Fig. 16 Wiring Diagram(HNF13060/A-D)