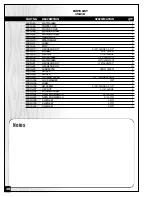

STEEL PLATEN ADJUSTMENT

The steel platen

should protrude 1/8” to 1/4”

(approx.) past the motor drive roller

and idle roller

in order to be in complete contact with the abra-

sive belt.

The steel platen is initially set at the factory but, due

to vibrations, over time, may need to be re-adjusted.

1.

Turn off and unplug the sander from the power

source.

2.

Remove the sanding belt. If needed, refer back to

section “Replacement of the sanding belt”.

3.

Use a straightedge or a combination square to

measure the clearance between the steel platen

and the drive roller

, and between the steel

platen and the idle roller

. If the width of the

gaps is more than 1/8” to 1/4” (approx.) or if the

width of both gaps is not more or less the same,

re-adjust the steel platen as follows:

4.

Loosen the two hex head bolts

using the sup-

plied 14 mm wrench or a 14 mm socket wrench,

then tap on one or both sides of the steel platen to

move it either forward or backward

until you

obtain a gap of 1/8” to 1/4” (approx.) between

the steel platen and each of the two rollers.

5.

Retighten the two hex head bolts then reinstall

the sanding belt.

LEFT SIDE VIEW

RIGHT SIDE VIEW

1/8” – 1/4”

LARGER VIEW

SPRING FATIGUE COMPENSATION ADJUSTMENT

Over time, repeated adjustment of the sanding belt

tension knob

will cause spring

fatigue. If you

don’t obtain proper tension by only adjusting the ten-

sion knob, loosen the nut

, then turn the adjustment

screw

clockwise. Retighten the nut.

Note: Turn the screw in 1 turn increments, recheck

and adjust again as needed.

LUBRICATION

Keep the tension mechanism hinge (located at the rear of the sander, beside the spring adjustment screw

) well

lubricated. Reapply lubricant on top of pin

(see picture above) as needed.

Note: Use any dry lubricant, available at any hardware store.

NOTE: The motor and all bearings are sealed and permanently lubricated – no further lubrication is required.

16

Содержание 15-010 M1

Страница 21: ...Notes 21...