5.

Remove the worn sanding belt and install a new

one onto the drums.

Tip: To extend belt life and avoid premature breakage, take note

of the direction arrows

printed on the inside of the sanding

belt to make sure you install the belt in the correct direction.

3.

Unscrew and remove the two lock knobs

then remove the top cover

.

4.

Loosen the two lock nuts

, then turn the tension

adjustment knob

clockwise until the sanding belt

is loose enough to be removed.

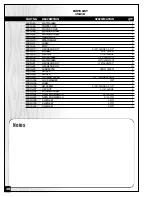

AUXILIARY TABLE UNDERSIDE VIEW

6.

Turn the tension adjustment knob counter-clockwise

until the sanding belt is tight around the drums,

then tighten the two

lock nuts

to lock the adjust-

ment knob.

AUXILIARY TABLE UNDERSIDE VIEW

Note: Belt tracking adjustments may be necessary after changing or replacing a sanding belt, to counterbalance for

unevennesses between sanding belts. If needed, refer back to section “Sanding Belt Tracking Adjustment”.

Helpful hint on sanding belt tension: Determining correct belt tension is somewhat subjective. It is learned

through experience and is somewhat dependant on personal preference. A properly tensioned belt will

last longer and be much less likely to break prematurely. If the belt is too loose, it will slip off during oper-

ation. A belt that is too tight will break prematurely. Make a sanding test and readjust if needed.

REPLACEMENT OF THE GRAPHITE COATING ON THE PLATEN

The graphite coating on the platen

will wear and over

time require replacement. Every 3 years (approx.) in small

shop settings and up to 10 years in home shop settings,

the graphite coating will begin to show visible signs of

wear and will need to be peeled off (using a solvent

based stripper) and removed. A replacement graphite

coated paper strip should be glued (with contact

cement) onto the platen in it’s place.

Note: Most retail outlets that sell stationary power tools and

abrasives products do stock graphite replacement strips for

most popular sizes of sanders.

15

Note: You first will have to remove the two knobs

and

the retaining plate

. Put them back in place

after the replacement coating has been glued for a bet-

ter adhesion.

Содержание 15-010 M1

Страница 21: ...Notes 21...