RATINGS

The operating and restraining coils are con

tinuous rated.

The tap setting used on the seal

in unit

is determined by the current drawn by

the contact circuit.

The 0. 2-ampere tap is for use with circuits

that operate on currents ranging from 0.2 up to

2 . 0 amperes at the minimum control voltage.

If

this tap is used with circuits requiring more than

2 amperes there is a possibility that the 7-ohm

resistance will reduce the current to so low a

value that the proper current may not be obtained.

The 2 .0-ampere tap should be used with circuits

that take 2.0 amperes or more at minimum con

trol voltage, provided the current does not exceed

30 amperes at the maximum control voltage.

If

the current exceeds 3 0 a mperes an auxiliary relay

should be used, the connections being such that

the current does not pass through the contacts

or the target and seal-in coil of the protective

relay.

The current-closing rating of the contacts is

30 amperes for voltages not exceeding 250 volts.

The current carrying ratings are affected by the

selection of the tap on the seal-in coil as indicated

in the following table:

Target and Seal-in C oil

Amperes, A-C or D-C

Function

2-Amp Tap

(0. 1 3 ohm)

0. 2-Amp Tap

(7 ohms)

Momentary Duty

30

5

Carry Continuously

0

0

BURDENS

Burdens for the Type

IJS

relays are listed

below. The burden

for

each circuit varies , depending

upon the phase displac ement

of

the two voltages,

from a minimum at 0 degree displacement to a

maximum near 180 degrees displacement.

I

CYCLES

i

CIRC UIT

I

5-6

I

I

5-6

1 1 5

60

7-8

I

I

7-8

I

I

5-6

1 1 5

50

5-6

7-8

I

7-8

Synchronism-Check Relays Type LJS GEH- 1791

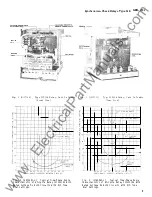

CONSTRUCTION

The relay components are mounted in a cradle

assembly which is latched into a drawout case when

the relay is in operation but they can be easily

removed when desired.

To do this, the relay is

first disconnected by removing the connection plug

which completes the electrical connections between

the case blocks and the cradle block. To test the

relay in its case this connection block can be

replaced by a test plug. The cover, which is attached

to the front of the relay case, contains an inter

lock arm which prevents the cover from being

replaced until the connection plugs have been in

serted.

The relay case is suitable for either semi

flush or surface mounting on all panels up tc, 2

inches thick and appropriate hardware is available.

However, panel thickness must be indicated on the

relay order to insure that proper hardware will

be included. For outline and drilling dimensions,

see Fig. 14.

RECEIVING, HANDLING AND

STORAGE

These relays, when not included as part of a

control panel, will be shipped in cartons designed

to protect them against damage. Immediately upon

receipt of a relay, examine it for any damage

sustained in transit.

If

injury or damage resulting

from rough handling is evident, file a damage claim

at once with the transportation company and promptly

notify the nearest General Electric Apparatus Sales

Office.

Reasonable care should be exercised in un

packing the relay.

If

the relays are not to be

installed immediately, they should be stored in their

original cartons in a place that is free from

moisture, dust, and metallic chips. Foreign matter

collected on the outside of the case may find its

way inside when the cover is removed and cause

trouble in the operation of the relay.

ACCEPTANCE TESiZi

Immediately upon receipt of the relay, an

inspection and acceptanc e test should be made to

insure that no damage has been sustained in shipment

and that the relay calibrations have not been dis-

PHASE

VOLTS

WATTS

P . F.

DIFF.

AMPS

oo

3 . 00

1 1 . 6

0.258

1 80°

3.76

1 2 . 0

0.3 13

oo

3 . 3 0

1 0.9

0.300

1 80°

4.07

1 1 .3

0.360

oo

4.35

14.2

0.306

180°

5.25

14.6

0.359

oo

4.75

1 3 . 3

0.357

180°

5.60

13.9

0.403

7

www

. ElectricalPartManuals

. com