3-1

Installation Environment

Install the drive in an indoor location that meets the following

requirements:

— The ambient temperature is between -10

°

C and +50

°

C

(+14

°

F to +122

°

F). (Remove the ventilation cover when

the temperature e40

°

C [+104

°

F].)

— The relative humidity is between 20% and 90%. Avoid

any location subject to condensation, freezing, or where

the drive would come in contact with water.

— Do not install in any location subject to direct sunlight,

dust, corrosive gas, inflammable gas, or oil mist.

— The drive should be installed at an elevation below

1000 meters (3281 feet). Installation above 1000

meters (3300 feet) will need to be derated 1% per 333

feet.

Example:

5 Hp, 460 VAC, output current 9 amps. Application

altitude 3900 feet.

% derate = x 1% = 1.8%

(9 amps) x

= 8.84 amps derated

output current.

Motor derate may also be required, contact motor

manufacturer.

— Vibration should be less than 0.6G.

Installation Mounting Clearance

CAUTION:

Because the ambient temperature greatly

affects drive life and reliability, do not install the drive in any

location that exceeds the allowable temperatures.

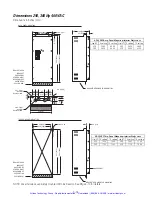

— Install at a sufficient distance from other equipment,

walls, or wiring ducts as shown in Figure 3-1 (these

clearances are required to allow the heat generated by

the drive to escape).

— Install the drive perpendicular to the ground and with

the lettering right side up. (If the drive is installed

upside-down or horizontally, heat build-up will occur.)

Section 3: Installation Guidelines

3900 - 3300

333

( )

100 - 1.8

100

( )

CAUTION:

The mounting wall for the drive must be constructed of

heat resistant material because during operation, the

temperature of the Inverter's cooling fins rises to approxi-

mately 90 degrees C (194

°

F).

NOTE:

When installing

two or more drives

in close

proximity, allow sufficient space as shown in Figure 3-1 and

install them in a horizontal row. If they must be installed in

a vertical column, at least 19.7 inches (50cm) internal

space must be provided between each one or a ventilation

baffle should be provided to prevent the ambient tempera-

ture from rising.

— Mounting screws or bolts should be of appropriate size

for weight of drive.

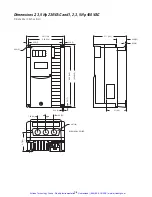

— See the appropriate view in Figure 3-2 for the location

of mounting holes.

— After removing the knockouts in the wiring lead in

plate, install the rubber bushings supplied to prevent

cable damage and to minimize dust entry.

Figure 3-1. DRIVE MOUNTING CLEARANCE

2.0” (5 CM)

or more

4.8” (12CM) or more

4.8” (12CM) or more

2.0” (5 CM)

or more

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Содержание Fuji Electric AF-300ES

Страница 32: ...3 16 Notes Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...

Страница 55: ...5 9 Notes Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...

Страница 58: ...5 12 Notes Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...

Страница 96: ...7 4 Notes Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...

Страница 122: ...10 6 Notes Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...

Страница 134: ...12 6 Notes Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...