Instructions for SL500DCL/SL800DCL

www.gatexpertstore.com

8

Step 4 - Motor Pad Footing

·

The motor pad concrete footing requires an area of no less than 500mm long x 350mm wide

and a minimum depth of 200mm (Standard requirement).

·

Ensure surface is level and parallel to the driveway.

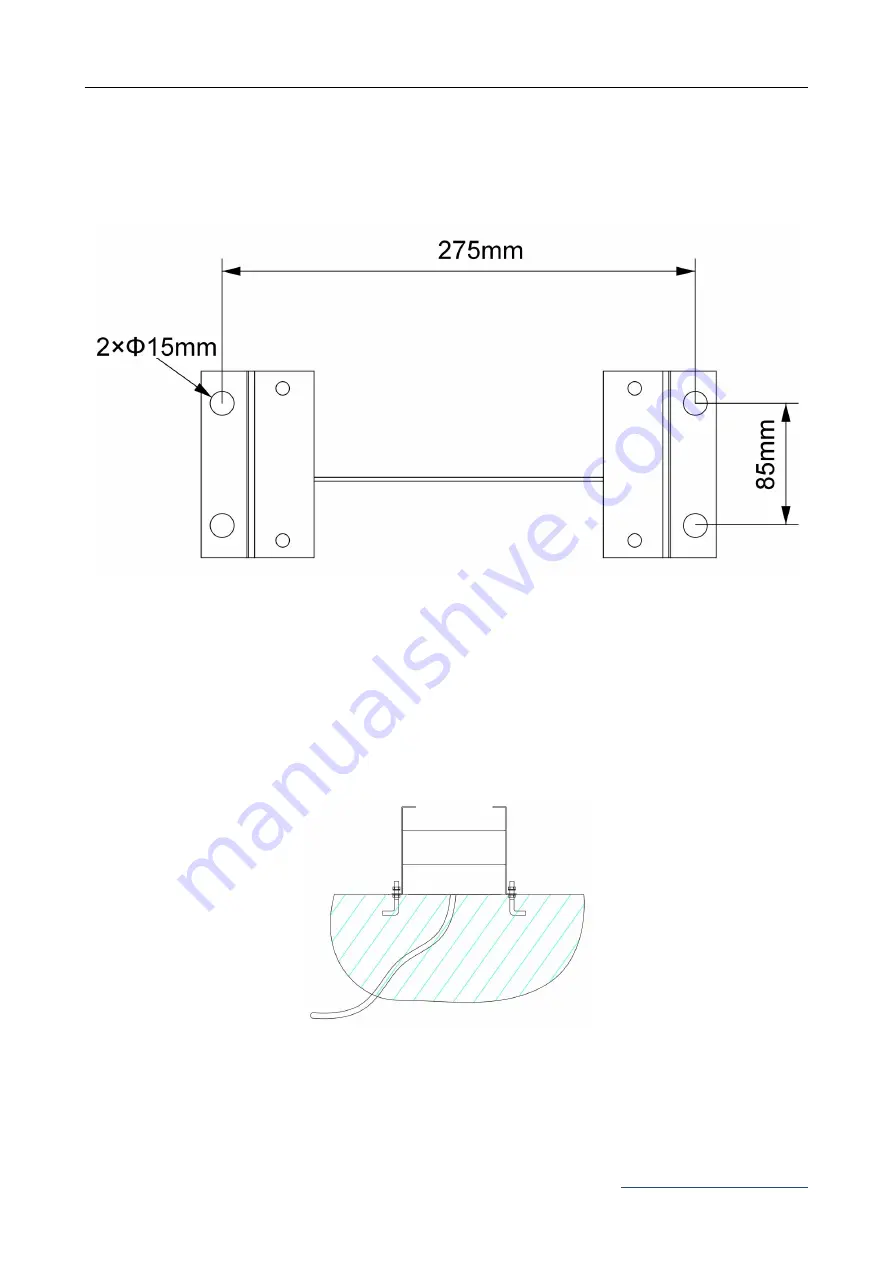

Mounting Plate Dimensions

Figure 9

Step 5 - Fitting Mounting Base and Motor

·

Fit anchor bolts(included in kit) or expansion bolts(should be prepared by users) according to

holes in mounting base (as per Figure 9).

·

Position the mounting base and fix it as per Figure 10.

·

Bolt motor to its base using the M8x40 bolts with spring and flat washers provided and tighten

as required.

Figure 10