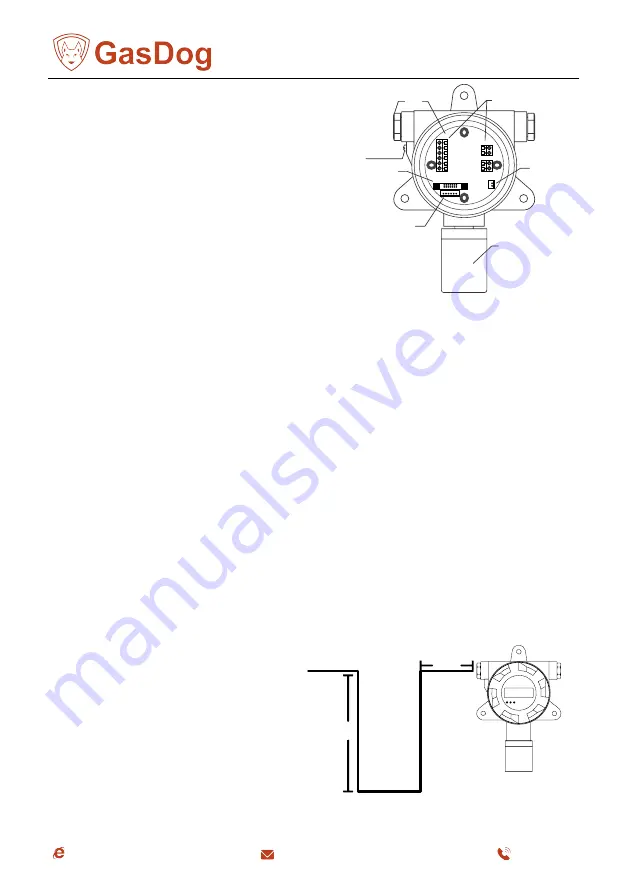

2 Structure diagram

1,Power supply and Signal line entrance and exit

2,Circuit board

3,Terminals

4,Sound and light alarm interface

5,Sensor head

6,Sensor head interface

7,Connect the claw socket to the mainboard

3 Installation method

Select the installation location

The installation position is very important to achieve the best detection effect.

When determining the location, it is necessary to comprehensively consider the following factors:

such as the density of the gas leak point, the specific gravity of the gas to be measured, the influence of

the surrounding buildings, the age of the production equipment, the wind direction and the weather

conditions all year round, etc. The location of doors and windows should also be considered indoors.

The following suggestions are for users' reference:

A. Appropriate distance should be maintained between the instrument and the possible leakage point of

the gas to be tested. If it is too close, the reaction speed will be very fast, but if the leakage is frequent, it will

cause too many alarms, or the long-term alarm state will make people paralyzed; if it is too far, the reaction

speed will be too slow, or even no response.

B. The instrument should be installed in the downwind direction of the leakage point.

C. When installing indoors, if the leakage source is outdoors, the instrument should be installed at

the air inlet.

D. The installation height should be determined according to the specific gravity of the measured gas and

air.

E. The number of instruments should be selected according to the possible leakage points of the gas to

be measured, the frequency of personnel appearance and the residence time, so as to achieve the best

detection effect.

F. If the equipment is outdated, it can be considered to increase the measured points.

G. The instrument should be prevented from being radiated by a high temperature heat source. Too

high or too low temperature will affect the use effect and lifetime of the sensors.

≥30CM

≤2CM

Cable

Figure H

IR AL AH

8.8.8.8

H. The instrument should be protected

from damp and rainwater inflow, which will

affect the internal circuit board.

The wiring recommendations are shown

in the diagram below.

Ground

connection port

5

6

1

2

3

4

7

4

www.gasdog.com

+86 773-280-9002