4517957 Rev. 2 (06/05)

Page 9

INSTALLATION continued

Commissioning:

The whole of the gas installation, including the meter,

should be inspected, purged and tested for leakage in

accordance with local codes.

1. Ensure that all controls are in the off position and

turn on the main gas supply and electrical mains.

2. Remove the screws securing the front fascia and

connect a U-gauge manometer to the pressure test

point on the main manifold. Operate the main

burners in accordance with the instructions given

in the User’s manual.

3. Check that the setting pressure is correct per

TABLE C on the previous page. If necessary, adjust

the pressure governor located at the rear of the

range, downstream of the shut-off valve, to give the

required setting.

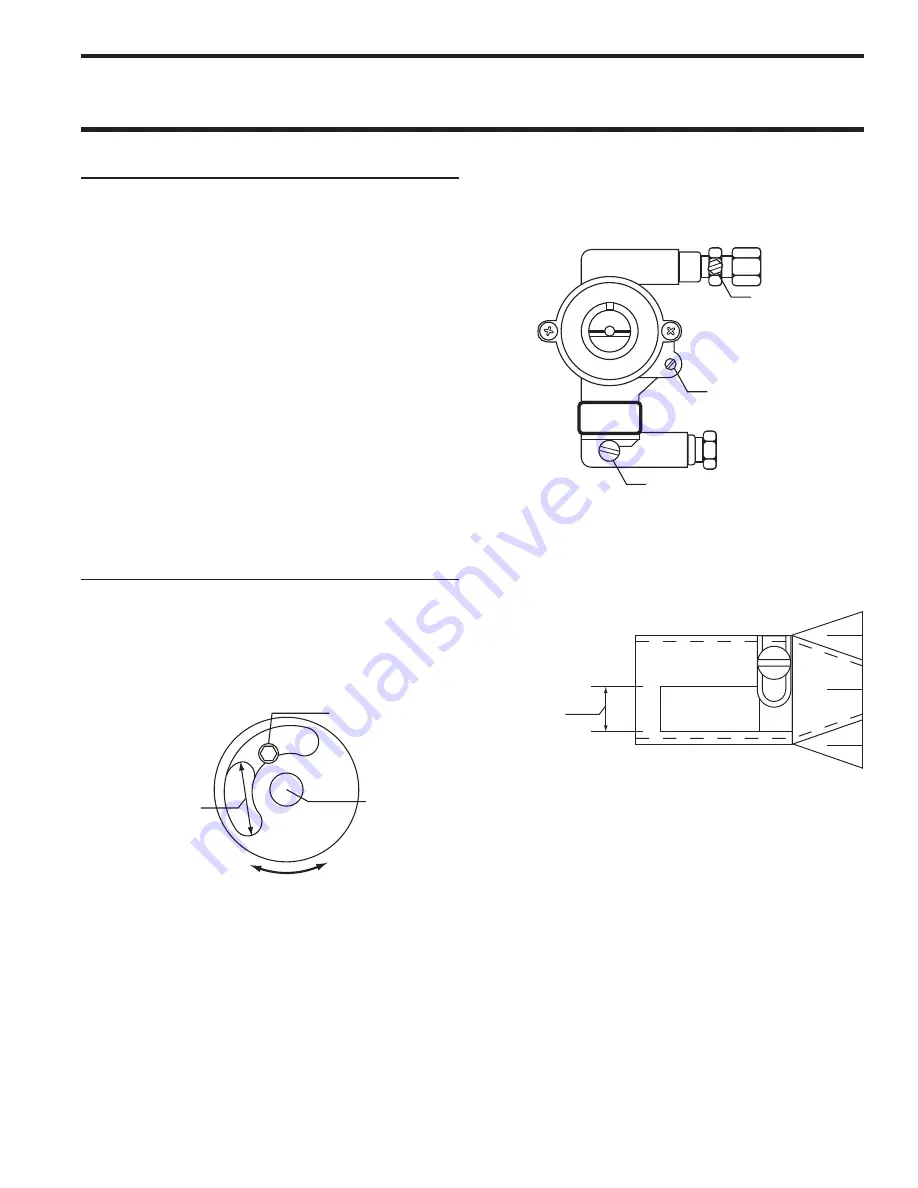

Burner Adjustments:

Griddle /Solid Hot Top Burner

Check that the aeration shutter is set to provide the

required opening per table E on the previous page. Adjust

if necessary.

FIXING SCREW

SHUTTER

OPENING

MEASUREMENT

INJECTOR

LOCATION

Hot Top Minimum Flame Setting

1. Set the gas tap to the MIN position.

2. Connect a U-gauge manometer to the pressure test

nipple located downstream of the gas tap.

3. With a flat screwdriver, turn the adjuster on the

body of the tap clockwise to reduce the pressure or

anti-clockwise to increase pressure. Set the pressure

to correspond with table D.

TEST POINT

LOW FLAME

ADJUSTER

PILOT

ADJUSTER

Oven Burner

1. Check that the aeration shutter is set to the required

opening per table E. Adjust if necessary.

SHUTTER

OPENING

MEASUREMENT

When all the settings have been checked, remove the U-

gauge manometer, replace the pressure test point screw

and the lower front panel.

Instruct the user or purchaser in the efficient and safe

operation of the appliance.

Tell the user of the location of the gas isolation cock

for use in an emergency. Leave this User Installation

and Servicing Instruction Manual with the user or

purchaser.

Содержание SRW286A

Страница 2: ...4517957 Rev 2 06 05 Page...

Страница 32: ......