Garford Weeding Implements

General Safety Instructions

Please read all of the safety instructions before commencing use of the implement.

Before carrying out mechanical repairs and adjustments

1.

Stop the tractor engine and apply the handbrake

2.

Turn off the hydraulic supply.

3.

If carrying out mechanical repairs or adjustments of the implement, shut down the Robocrop computer

system and switch off the power via the rocker switch on the side of the console.

4.

If the hydraulic system includes accumulators which store hydraulic pressure even when the tractor

supply is turned off, ensure the system is depressurised and allow oil to return to the tractor by

positioning the hydraulic lever in the float position. There are two pressure gauges on the hydraulic

system at the front of the implement, ensure they both read zero before carrying out repairs or

adjustments.

5.

If the implement has an electric power pack, switch the isolator to the off position.

6.

If possible lower the implement to the ground before working on it.

7.

Never work under a raised implement unless it is supported by suitable jack stands.

8.

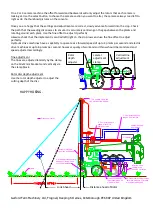

Be aware of potential trap and shear points on the unit parallel linkages, the freeshift and the disc steer

units with self levelling, and do not put yourself at risk.

While changing settings on the computer the operator should ensure other persons do not try to make repairs

or adjustments to the implement and keep other persons well clear of the implement.

Never conduct maintenance work on the side shift or disk steering mechanisms while they are supporting the

weight of the implement.

Regularly check the condition of electric cables, hydraulic hoses and fittings and tightness of nuts and bolts etc.

If the hydraulic supply manifold is fitted with a hydraulic accumulator. Discharge the accumulator before

disconnecting the implement from the tractor.

Freeshift

Disc steer

Parallel

linkages

Pressure

gauges

Parallel

linkages

with self

levelling

Содержание Robocrop Inrow Weeder

Страница 1: ...Operator Instructions...