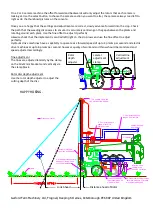

Robocrop InRow Weeder – Setup Guide

Setting up the Robocrop InRow Weeder consists of..

mechanical alignment of the weeding units

mechanical alignment of the cameras

configuration file settings

The inter relationship between all of these settings is critical

; if one is wrong the weeder will not work

accurately. The accuracy of taking measurements and setting the weeder will be reflected in the accuracy of

work.

It is the operator’s responsibility to measure the crop and adjust the implement and computer settings to match

the crop.

1)

The implement must be set up physically to suit the crop you are working on.

i)

Set the disc steer wheel track width to suit the crop track width

ii)

Set the weeder row units to suit the row widths to be worked (Always take these measurements from

the crop in the field to be worked).

iii)

Ensure the rotor disc size fitted suits the crop to be worked and the setting shown on the setup

screen. The disc size should be equal to or smaller than the plant spacing to be worked. The physical

measurement across the wide part of the disc is approximately half the disc design size i.e 126mm

disc width = 25cm disc size.

Disc size designation is a special code

e.g. 16-4W6

1

st

part (16) is the crop spacing design size

2

nd

part (4) is the design offset between crop centre line and rotational axis of the disc

3

rd

part (W) specifies a Weeding disc, alternative =T, a Thinning disc

4

th

part (6) is the plant zone to be left by the disc

The numerical reference is in centimetres.

10005

8619

8614

8619

8614

8619

8614

8619

8614

8677

8677

8677

8719

8093

8091

130

8093

8091

130

8570r2

8673

8672

8673

8672

8673

8672

8673

8672

8673

8672

8673

8672

8673

8672

8673

8672

10007

9735 SL 50W

7749

7744

180

7749

7744

180

7749

7744

180

16-4W6

8543

Leg

18-4W6

8543

Leg

21-4W6

Leg

8495

25-4W7

Leg

8495

29-4W7

Leg

8495

33-4W7

Leg

8495

29-6W10

8684

Leg

33-6W10

8684

Leg

38-6W10

8684

Leg

45-6W10

8684

Leg

16-4W6

18-4W6

21-4W6

25-4W7

29-4W7

33-4W7

29-6W10

33-6W10

38-6W10

45-6W10

2)

Switch on the hydraulic supply and console and allow the system to test and park the rotors.

Содержание Robocrop Inrow Weeder

Страница 1: ...Operator Instructions...