m

A new saw chain stretches, requiring adjustment after as few as 5 cuts. This is

normal with a new chain, and the interval between future adjustments will lengthen

quickly.

m

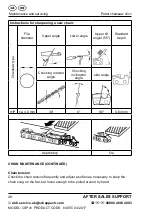

If the saw chain is

TOO LOOSE

or

TOO TAUT

, the drive wheel, chain bar, chain and

crank shaft bearing will suffer premature wear. Fig. 4/pos. X2 shows the correct tension

(when cold) and Fig. 4/pos. X3 shows the tension (when warm). Fig. 4/pos. X1 shows a

chain that is too loose.

3. CHAIN BRAKE MECHANICAL TEST

Your chainsaw is equipped with a chain brake that reduces the possibility of injury due

to kickback. The brake is activated if pressure is applied against the brake lever when,

as in the event of kickback, the operator's hand strikes the lever. When the brake is

actuated, chain movement stops abruptly.

m

WARNING

The purpose of the chain brake is to reduce the possibility of injury due to kickback;

however, it cannot provide the intended measure of protection if the saw is operated

carelessly. Always test the chain brake before using your saw and periodically while on

the job. (See below for details of how to perform a test of the mechanical brake).

4. TO TEST CHAIN BRAKE

•

The chain brake is

DISENGAGED

(chain can move) when the

BRAKE LEVER (5) IS

PULLED BACK (Fig. 11/pos. 2) AND LOCKED

shown in Fig. 11.

•

The chain brake is

ENGAGED

(the chain is locked) when the brake lever (5) is pulled

forward and the mechanism (shown in Fig. 10) can be seen. It should not be possible

to move the chain (Fig. 30).

m

WARNING

The brake lever should snap into both positions. If strong resistance is felt, or the lever

does not move into either position, do not use your saw. Take it immediately to a

professional Service Centre for repair.

5. FUEL AND OIL – RECOMMENDED FUELS

Use only a mixture of unleaded petrol and special 2-stroke engine oil. Mix the fuel

mixture as indicated in the fuel mixing table.

36

AFTER SALES SUPPORT

00800 4003 4003

MODEL: CSP41 PRODUCT CODE: 64055 04/2017

Set up

Petrol chainsaw 41cc