11

2 TECHNICAL DESCRIPTION OF THE BOILER

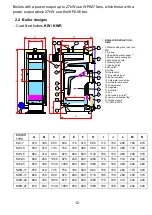

2.1 Water wall of KW, KWR, KWRU boilers

The heat exchanger in heating boilers is made

of furnace sheet metal with

a thickness of 5÷ 8mm. Depending on the power output of the boiler

(5mm

for 37kW, 6mm for 60kW, 7mm - 75kW, 8mm - 100kW). From the outside the

water wall uses sheet metal that is 4mm thick (5mm for boilers above 75kW).

KW boilers are equipped with a removable cast iron grate, whose elements

can be replaced when they become deformed.

KWR boilers are equipped with a fixed water-cooled grate, which enables

them to transfer heat from the fuel burned more efficiently. Exhaust gases flow

from the firebox to the exhaust channels, pass alongside the vertical water heat

exchanger tubes and dissipate heat through the steel walls and into the water.

In boilers with bottom combustion (labeled "d'') a cast iron plate is installed,

which stops the flow of exhaust gases from the combustion chamber to the flue.

Exhaust gases then flow behind the firebox water heat exchanger (extended

exhaust) and the fuel on the grate burns gradually, allowing stable control over

the boiler's power output.

KWRUZ boilers are equipped with a fixed water-cooled grate, which enables

them to take heat from the fuel burning on the hearth more efficiently. Exhaust

gases flow from the firebox to the exhaust channels behind the chamber, pass

the vertical water heat exchanger and dissipate heat through the steel walls and

into the water. With these boilers it is possible to achieve combustion from the

bottom by ignition from the top through the fuel loading hatch. The air from the

fan passes over the cold fuel and only the upper part of it burns. The boiler's

power output is reduced by the area of the chamber walls occupied by the cold

fuel. Fuel burns gradually allowing for stable control over the power output of

the boiler. The boiler achieves maximum power output when fuel burns directly

on the grate. Before lighting, move the lever to lift the rear flap of the vertical

heat exchanger. When the chimney is warmed up (~ 1 minute), release the

lever.

The construction of the boiler allows for efficient heat exchange through

exhaust gas recirculation in the horizontal heat exchanger channels in KW and

KWR boilers, and vertical heat exchanger channels in KWRU boilers. The

reverse-convection channels can be cleaned through the front hatch of the

boiler or the top cleaning hatch in KWRU boilers. In the case of KWRUZ boilers,

cleaning of heat exchangers is done after the top cover of the boiler is removed.

Boilers can be equipped with:

- a thermostatic draught regulator for controlling the flow of air to the fuel,

depending on the temperature in the boiler

- a fan and LUXUS controller for monitoring the boiler's operation (fan operation

based on temperature) and circulation pumps installed in the heating system.

The LUKSUS controller is not equipped with a domestic hot water sensor and

domestic hot water (DHW) pump hose as standard.

The fan can be mounted on the side of the boiler or in the air intake flap on the

door of the ash pan.

Содержание KW-10

Страница 2: ...2 www galmet com pl ...

Страница 3: ...3 ...

Страница 4: ...4 ...

Страница 5: ...5 ...

Страница 23: ...23 ...