3

CONTENTS

CONTENTS

CONTENTS

CONTENTS

CONTENTS

1 INTRODUCTION

1 INTRODUCTION

1 INTRODUCTION

1 INTRODUCTION

1 INTRODUCTION

2 OPERA

2 OPERA

2 OPERA

2 OPERA

2 OPERATOR CONTROLS

TOR CONTROLS

TOR CONTROLS

TOR CONTROLS

TOR CONTROLS

3 TECHNICAL INFORMA

3 TECHNICAL INFORMA

3 TECHNICAL INFORMA

3 TECHNICAL INFORMA

3 TECHNICAL INFORMATION

TION

TION

TION

TION

5 COMMISSIONING

5 COMMISSIONING

5 COMMISSIONING

5 COMMISSIONING

5 COMMISSIONING

7 F

7 F

7 F

7 F

7 FAUL

AUL

AUL

AUL

AULT FINDING

T FINDING

T FINDING

T FINDING

T FINDING

CONTENTS

CONTENTS

CONTENTS

CONTENTS

CONTENTS

Impor

Impor

Impor

Impor

Important Information

tant Information

tant Information

tant Information

tant Information -----------------------------------------

-----------------------------------------

-----------------------------------------

-----------------------------------------

----------------------------------------- 4

Section 1 Intr

Section 1 Intr

Section 1 Intr

Section 1 Intr

Section 1 Introduction

oduction

oduction

oduction

oduction

1-1 Introduction ---------------------------------------------- 5

1-2 System Layout ------------------------------------------- 8

1-3 Parts Supplied------------------------------------------- 11

1-4 The Electrastream System ------------------------------- 12

1-5 Tri Core Heater Operation -------------------------------- 13

Section 2 Operator Contr

Section 2 Operator Contr

Section 2 Operator Contr

Section 2 Operator Contr

Section 2 Operator Controls

ols

ols

ols

ols

2-1 System Control ------------------------------------------ 14

2-2 Electrastream Control Unit ------------------------------- 16

2-3 Shut Off Valves ------------------------------------------ 20

2-4 Temperature & Pressure Relief Discharge ---------------- 22

2-5 Thermostatic Mixing Valve ------------------------------ 22

2-6 Servicing ------------------------------------------------ 22

Section 3 T

Section 3 T

Section 3 T

Section 3 T

Section 3 Technical Information

echnical Information

echnical Information

echnical Information

echnical Information

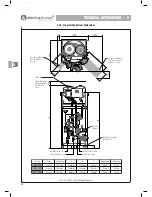

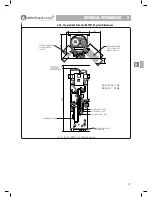

3-1 Specifications ------------------------------------------- 23

3-2 Dimensions --------------------------------------------- 25

3-3 Wiring --------------------------------------------------- 29

Section 4 Installation

Section 4 Installation

Section 4 Installation

Section 4 Installation

Section 4 Installation

4-1 Building Control ----------------------------------------- 31

4-2 Electrical ------------------------------------------------ 31

4-3 Hot Water System --------------------------------------- 33

4-4 Heating System ----------------------------------------- 37

4-5 Expansion Discharge ------------------------------------ 40

4-6 System Pressure ---------------------------------------- 43

4-7 Electrastream Connections - ---------------------------- 44

Section 5 Commissioning

Section 5 Commissioning

Section 5 Commissioning

Section 5 Commissioning

Section 5 Commissioning

5-1 Commissioning ----------------------------------------- 47

Section 6 Servicing

Section 6 Servicing

Section 6 Servicing

Section 6 Servicing

Section 6 Servicing

6-1 Routine Service ----------------------------------------- 50

Section 7 Fault Finding

Section 7 Fault Finding

Section 7 Fault Finding

Section 7 Fault Finding

Section 7 Fault Finding

7-1 Fault Finding -------------------------------------------- 52

Health & Safety

Health & Safety

Health & Safety

Health & Safety

Health & Safety ------------------------------

------------------------------

------------------------------

------------------------------

------------------------------ Inside Front Cover

6 SERVICING

6 SERVICING

6 SERVICING

6 SERVICING

6 SERVICING

4 INST

4 INST

4 INST

4 INST

4 INSTALLA

ALLA

ALLA

ALLA

ALLATION

TION

TION

TION

TION

IMPORTANT

BEFORE STARTING THE INSTALLATION OF THE ELECTRASTREAM CHECK ALL COMPONENTS HAVE

BEEN DELIVERED AND ARE IN SATISFACTORY CONDITION - Refer to 1-3 .

HEAL

HEAL

HEAL

HEAL

HEALTH & SAFETY

TH & SAFETY

TH & SAFETY

TH & SAFETY

TH & SAFETY

33

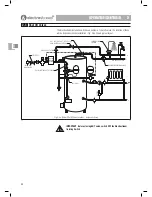

4-3

Hot Water System

4-3.1 Unvented Hot Water Cylinder

The cylinder may be installed at any convenient above ground location within the

property. As Electrastream is a sealed system, the cylinder is equally effective on any

floor.

The cylinder must always be installed vertically.

Avoid positioning the cylinder where it may be subjected to frost.

The floor must give adequate support to the filled cylinder.

Cylinders must have frost protection when they are installed where low temperatures

could be a potential problem - see 1-4.8.

Cylinders with legs are supplied with self-tapping screws for floor fixing.

For servicing and cylinder replacement, clearance is required all round the cylinder -

recommended 100mm minimum.

The cylinder must be fitted with a drain valve, this should be as low as possible and able

to drain at least 80% of the cylinder’s volume.

The cylinder may be installed below ground i.e. in a basement, providing that the

expansion relief discharge pipe is plumbed to a metal receptacle with a suitable pump

and switch arrangement, current Building Regulations give details of this. An alternative

is to use a Hepworth HepvO Self Sealing Waste Valve, this must be installed to the

manufacturers specification and building regulations.

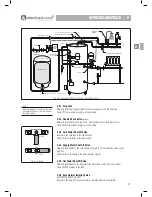

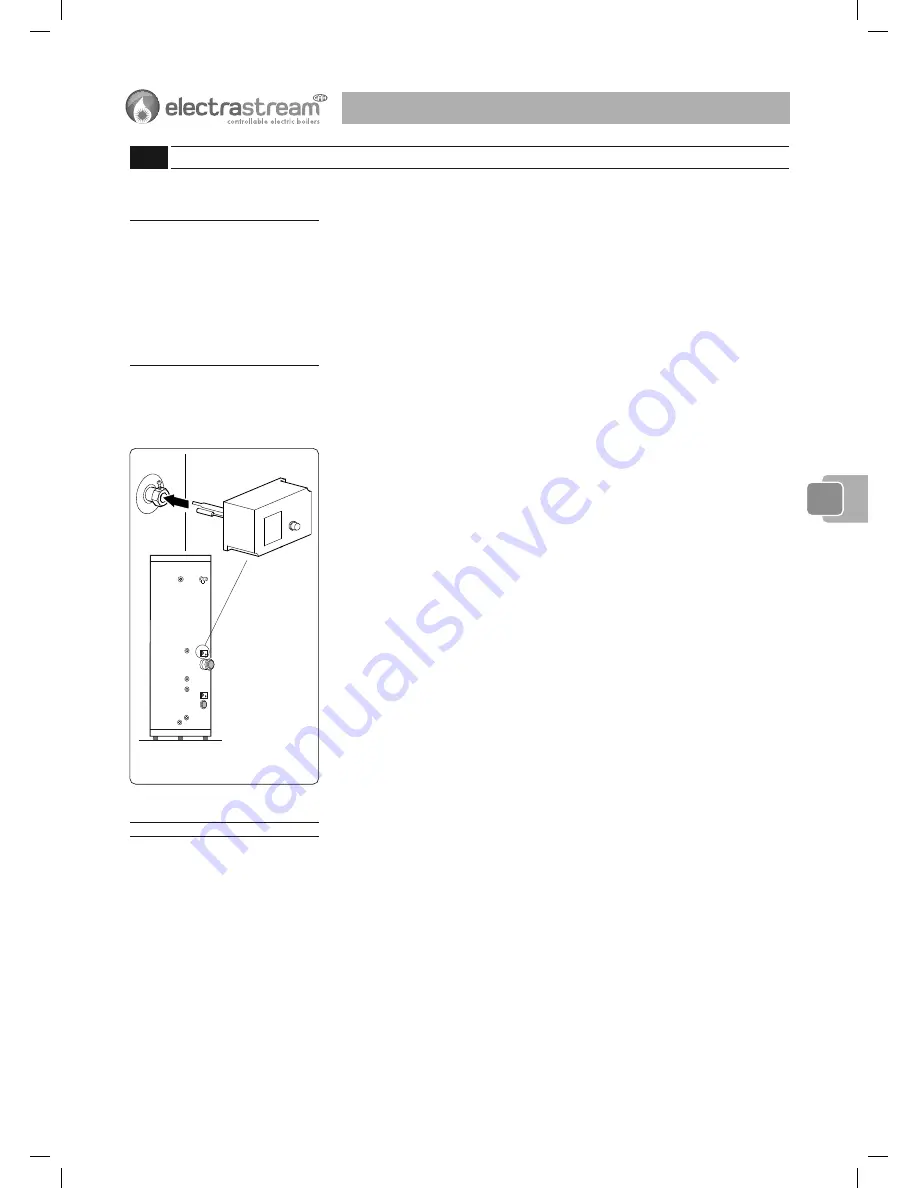

4-3.2 Cylinder Temperature Sensor & Over Temperature Cut-Out Box

The cylinder temperature sensor and over temperature cut-out box is an integral part of

the Electrastream control system. The Electrastream must not be switched on if the box

is not fitted.

The unit consists of a temperature sensor and over temperature cut-out device, both are

wired back to the Electrastream control unit - see wiring diagrams figs. 3-3a and 3-3b.

The box must be fitted to the cylinder with its phial and sensor inserted into the socket

provided (located above the tri-core heater). A screw is provided to clamp it securely in

place.

The box is supplied pre-wired. If the cables need to be extended use suitable rated

cables and ensure they are correctly jointed, sleeved and covered.

4-3.3 Combination Valve

Refer to figs. 4-3b and 4-3c.

The Combination Valve is supplied separate, it has to be fitted to the pipework supplying

the cylinder.

For standard configurations see figs. 1-2a and 1-2b.

The valve has an integral 3.5 Bar Pressure Reducing Valve and a 6 Bar Expansion Relief

Valve. It also has an in-line strainer, this should be checked as part of routine inspection.

No shut off or isolation valves should be fitted between the combination valve and the

cylinder.

INST

INST

INST

INST

INSTALLA

ALLA

ALLA

ALLA

ALLATION 4

TION 4

TION 4

TION 4

TION 4

Fig. 4-3a Cylinder Temperature & Over

Temperature Cut-Out Box

Note

For wiring see figs. 3-3a and 3-3b.

Note

The Electrastream system must not be

installed in any enclosed space where the

air temperature could exceed the

maximum electrical design ambient of

30°C.

Adequate ventilation should be provided

for airing cupboards and enclosed

compartments.

Humidity may also present a problem

within airing cupboards.

TWIN COIL CYLINDER

44444

Содержание Electrastream

Страница 55: ...55 ...