4

ESD5300 Speed Control Unit

09-2020-H

PIB1041

Governors America Corp. © 2020 Copyright All Rights Reserved

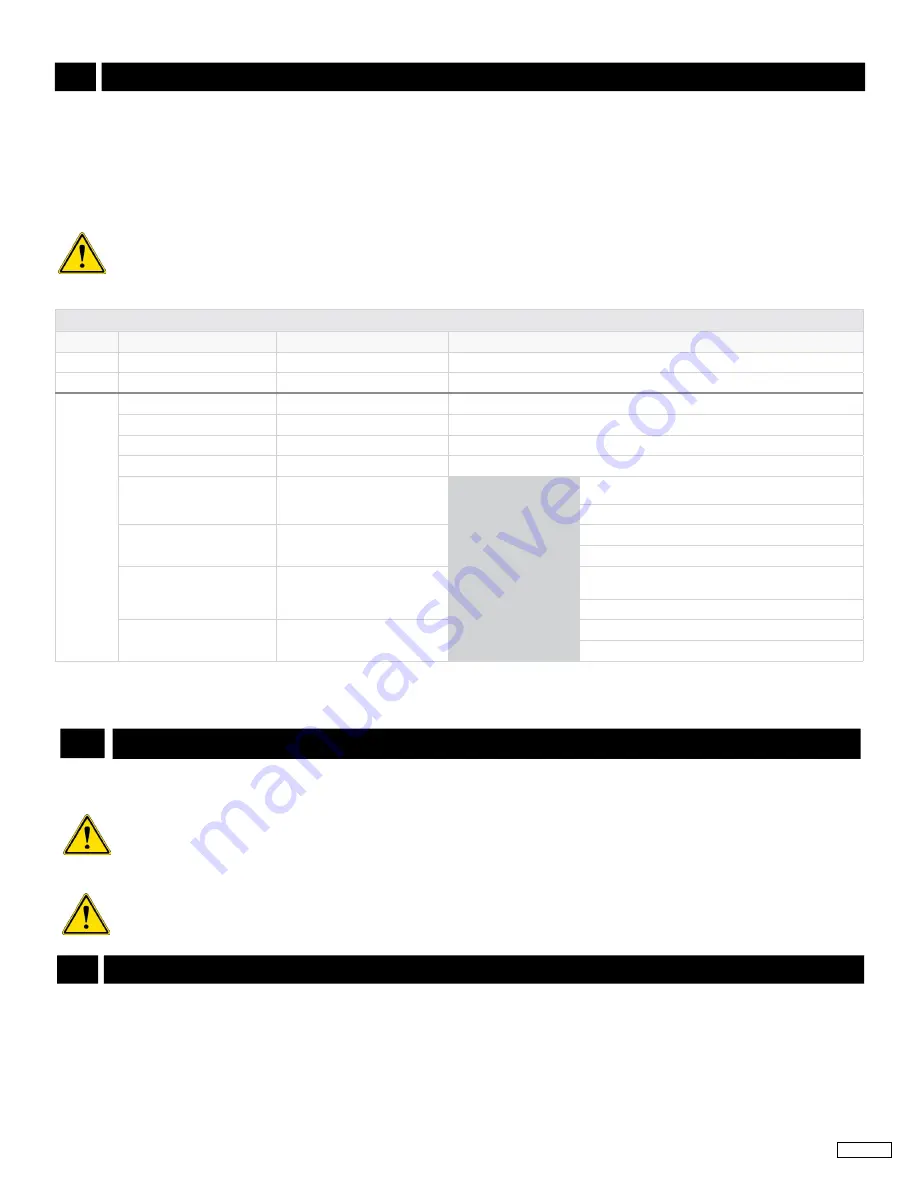

PRE-START SETUP

5

Before starting the engine, preset at minimum the following adjustments.

1. Set GAIN, STABIlITY, and external Frequency Trim (if used) are set to their mid point (50) positions.

2. Set STARTING FUel is set to 100 initially.

3. ensure Dip Switches SW2-5, SW2-6, and SW2-7 are set in their normal positions before starting the engine as shown in the DIP

SWITCHeS table below.

4. Set all other Dip SW2 switches (1 - 4) for optimum engine performance per the DIP SWITCHeS table. Take into account the factory

speed setting for the controller is 1400 Hz, or approximately set to idle speed. The crank termination is set very low initially.

*

When switch C2 is ON, the Soft Coupling feature is enabled.

**

SW2 Switches 5-8 must be set to match the actuator being used in the application. Contact GAC for questions.

DIP SWITcHeS

roW

SWITcH

fUncTIon

normaL PoSITIon

SW1

1

lead lag Circuit

OFF

2

Soft Coupling

OFF

SW2

1

DTC 8X

OFF

2*

DTC 4X

OFF

3

DTC 2X

OFF

4

DTC 1X

OFF

5**

(adjust with engine

stopped)

Speed loop Gain 4X

for actuator

Series

120, 225, 175, 275 = ON

335, 2001 = OFF

6**

Act loop Gain

(7 A MAX) (15 A Peak)

for actuator

Series

120, 225, 175, 275 = ON

335, 2001 = OFF

7**

Act loop Gain

(7 A MAX) (15 A Peak)

for actuator

Series

120, 225, 175, 275 = OFF

335, 2001 = ON

8**

Added DTC 11 ms

65 ms

for actuator

Series

120, 225, 175, 275 = OFF

335, 2001 = ON

6

START ThE ENgINE

If crank termination occurs too quickly preventing the engine from starting, turn the crank termination adjustment clockwise (CW). The

actuator should snap to full fuel until the engine starts and run at a low idle setting. Adjust the SPeeD setting CW for the desired oper-

ating speed. If the engine is still unstable, turn the GAIN and STABIlITY adjustments CCW until the engine is stable.

If the IDle speed adjustment is set too low, the engine may never exceed the crank termination point, possibly causing starter

damage.

If the system remains unstable or not operating properly, see SeCTION 10, System Troubleshooting.

Read this entire document before starting your engine.

7

gOVERNOR SPEED SETTINg

The governed speed set point is increased by clockwise rotation of the SPeeD adjustment pot. Remote speed adjustment can be ob-

tained with an optional 5K Frequency Trim Control. See Section 4, WIRING for more information.

Failure to set these dip switches may cause startup engine trouble. See Section 10, System Troubleshooting, SW2

SWITCH SeTTINGS FOR INSTABIlITY table for additional information.