Technical Documentation G.Mondini S.p.A. Tray Sealer TRAVE-350

2

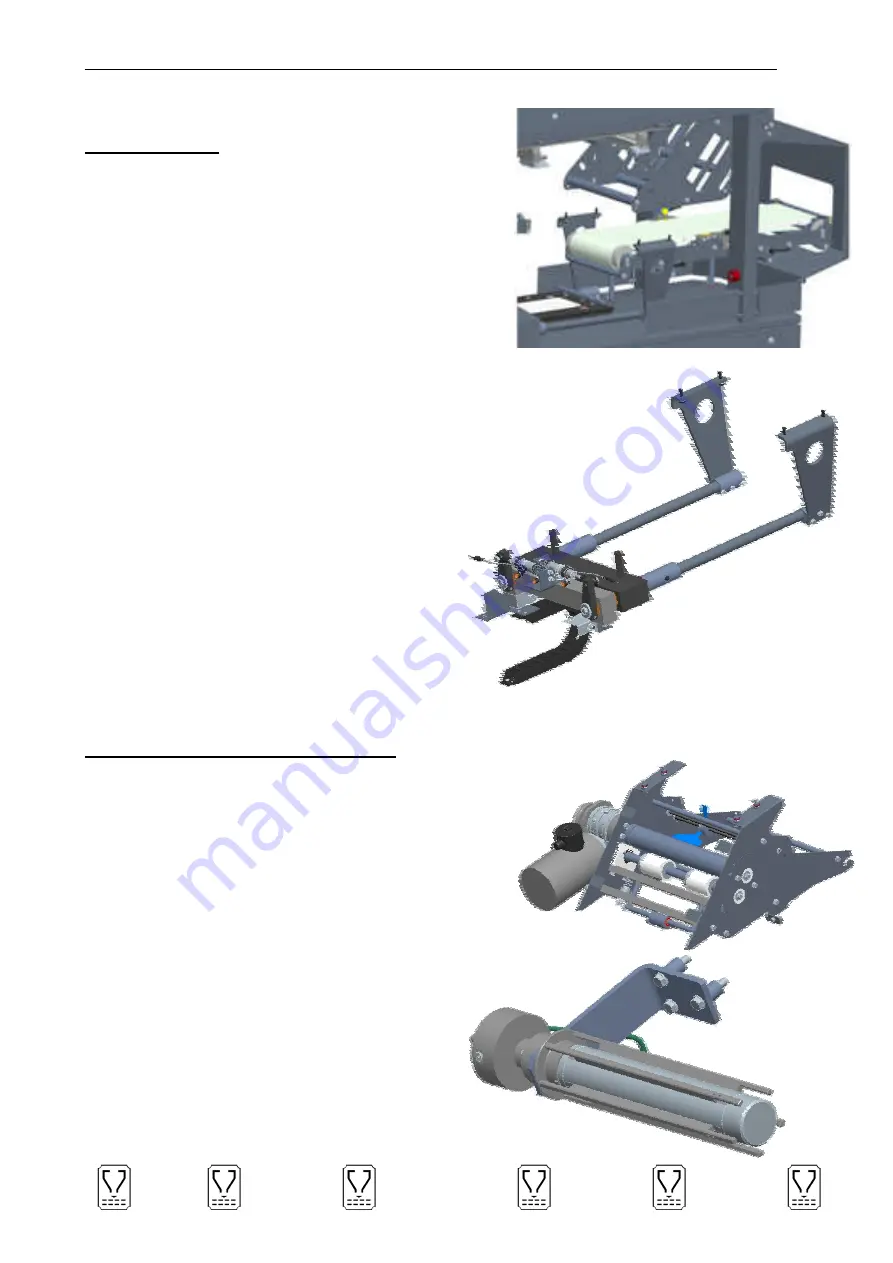

Tray handling.

To

avoid

tray

shaking

and

excessive

deceleration and acceleration of the product

inside the tray, the handling is extremely

smooth and accurate.

Trays are moved from the smart belt to the

sealing station through moving arms, which are

gripping the group from the side. These arms

are controlled by a servomotor system, whose

main characteristics are smoothness, high speed,

consistency, accuracy and extremely low

maintenance and by a long-stroke pneumatic

piston for the rotation to allow a very good

smoothness and a wide range of settings.

Film unwinding and waste rewind.

Film saving and reliable continuous run are at

the base of the development of the system

incorporated in this tray sealer. The reel is

positioned on a cantilever shaft which is

connected to a servomotor. Film is kept in

tension through several shafts, which are

supported both sides to avoid any misalignment.

A dancing bar keeps a constant tension on the

film during the unwinding.

The film is pulled through the tool via two

counter rotary rollers, controlled by an electrical

motor, which allows smooth pulling to reach the

maximum waste savings. A clutch controls the

tension on the continuous running film waste

rewind.