8-1

Chapter 8 PROTECTIVE FUNCTIONS

If any inverter protective function is activated to issue an alarm, the inverter displays the

corresponding alarm code on the LED monitor of the keypad and shuts down its output.

Accordingly, the motor coasts to a stop.

Table 8.1 lists alarm codes related to the PG interface card. For other alarm codes, refer to the

FRENIC-Multi Instruction Manual (INR-SI47-1094-E), Chapter 6 "TROUBLESHOOTING."

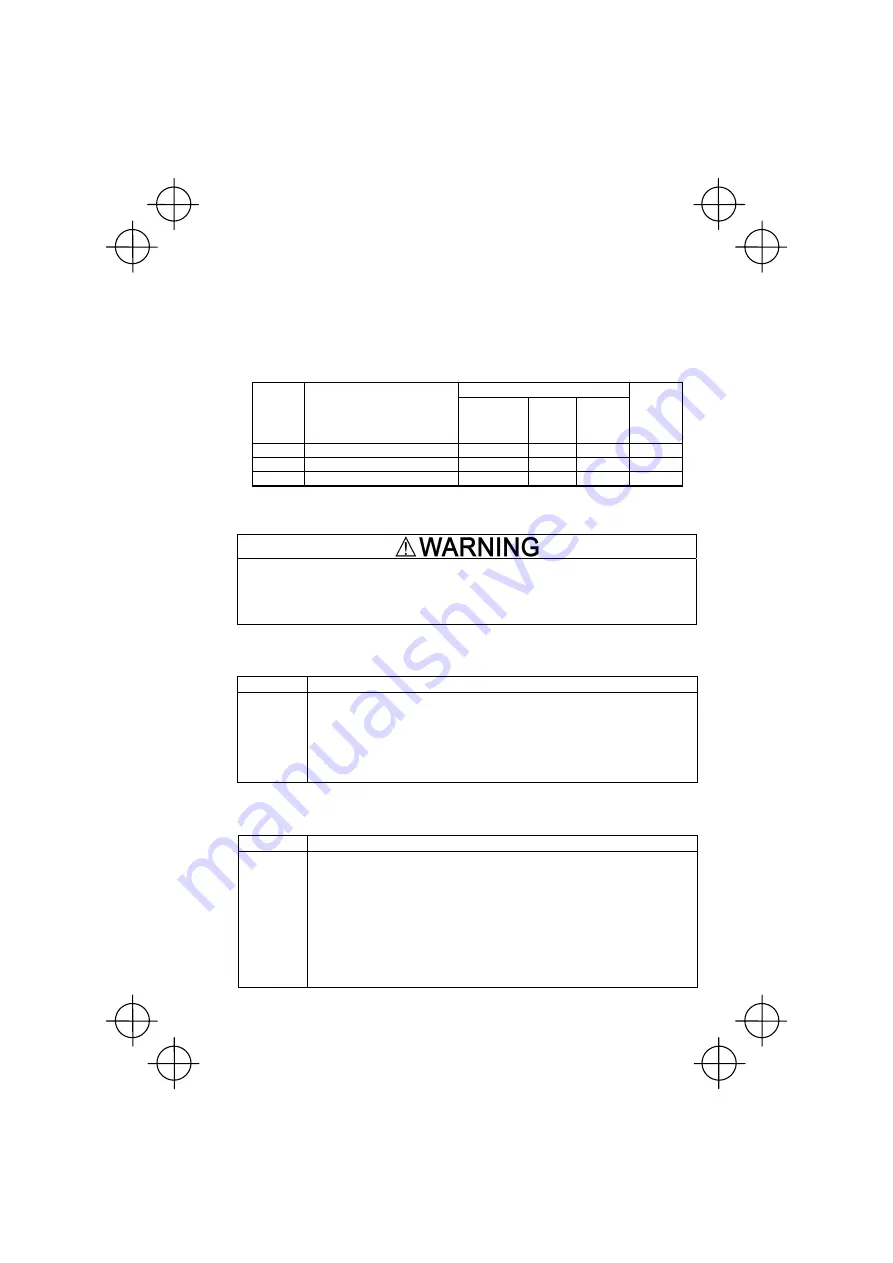

Table 8.1 Related Alarm Codes

Alarm for:

Alarm

code

Alarm name

Frequency

control

with pulse

rate input

Speed

control

Positioning

control

Refer to

Section:

os

Overspeed alarm

NA

Y

NA

8.1

ere

Excessive speed deviation alarm

NA

C

NA

8.2

ero

Positioning control alarm

NA

NA

Y and C

8.3

Y: Always active. The protective function for the alarm is always active when the control is enabled.

C: Conditionally active. The protective function for the alarm is active when the control is enabled

and the protective function is enabled with the function code. The factory default is "enabled."

NA: Not available when the control is enabled.

If any of the protective functions has been activated, first remove the cause. Then, after

checking that the all run commands are set to off, reset the alarm. Note that if the alarm is

reset when any run command is set to on, the inverter may supply the power to the motor

which may cause the motor to rotate.

Injury may occur.

8.1 Overspeed

Alarm

(

os

)

Table 8.2 Overspeed Alarm Specifications

Alarm code

Descriptions

os

•

The inverter issues this alarm when the detected speed exceeds the 1.2 times the

minimum value of either (1) or (2) below.

(1)

For the selected motor,

Maximum frequency (F03 or A01) + Torque limiter (Frequency increment limit for

braking, H76)

(2) Frequency limiter, High (F15)

•

This protective function works when the inverter is outputting with the speed control

with PG being enabled (F42 or A14 = 3 or 4 and

PG/Hz

is ON).

8.2 Excessive Speed Deviation Alarm (

ere

)

Table 8.3 Excessive Speed Deviation Alarm Specifications

Alarm code

Descriptions

ere

•

This protective function recognizes a PG error by software based on the relationship

between the speed command and the detected speed.

•

When the speed deviation between the speed command and the detected speed

has exceeded the excessive speed deviation level specified by o17 during the period

longer than the timer setting specified by o18, the protective function issues this

alarm.

•

This protective function provides two choices--"Stop running" (o19 = 1 or 2) and

"Continue to run" (o19 = 0) when it is activated. When the latter is selected, the

inverter continues to run with output to terminal [Y] without issuing an alarm.

•

This protective function works when the inverter is outputting with the speed control

with PG being enabled (F42 or A14 = 3 or 4 and

PG/Hz

is ON). It does not, however,

during DC braking or idling due to overload.

Содержание FRENIC-Multi Series

Страница 38: ...MEMO...