Page

20

of

28

Fuji Electric Europe GmbH

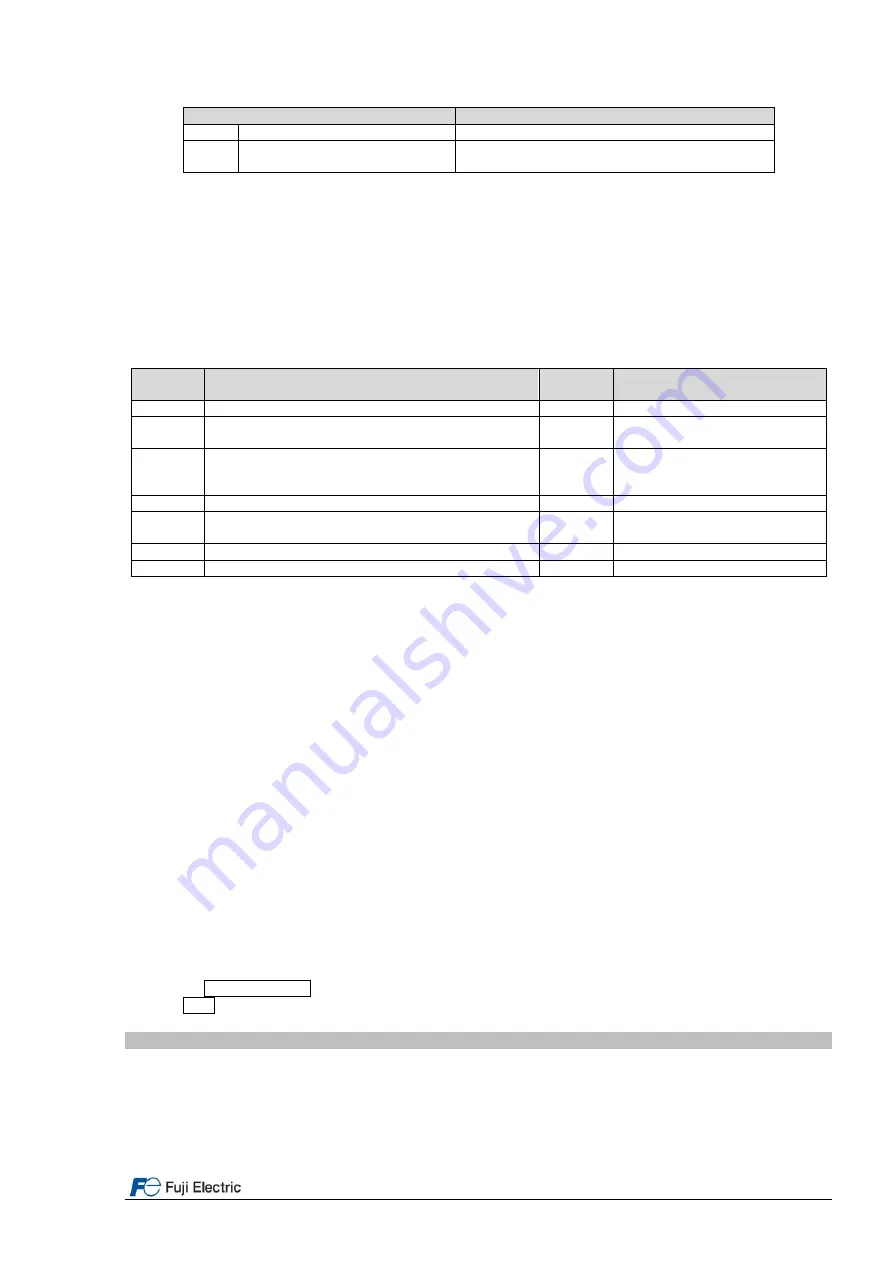

Table 9.1: Initialization types

Initialization type

Function

0

Disable initialization

Does not initialize. Data set by the user is kept.

3

Vector control for IM (open loop)

Initialize all function code data to settings suited

for open loop control for IM.

Default control mode in LM2C is Torque vector control (F42=2). V/f control is available as well when F42=3. In

V/f control slip compensation (P12) is not active, therefore the stopping level of the lift car might be dependent

on the car load.

8.2 Specific setting

Motor parameters, in other words motor name plate, have to be set manually. Table 9.2 shows the basic setting that

needs to be set. Parameters has to be set in the same order shown in the table below, otherwise a malfunction may

occur.

Table 9.2. Basic setting for induction motors (IM).

Function

Meaning

Factory

setting

Comments

P01

Motor poles.

4

Depends on the motor.

F03

Motor’s rated speed.

Normally F03 is motor speed at nominal lift speed.

1450 rpm

F04

Motor’s synchronous speed.

For 4-pole motors (50Hz) is 1500 r/min, for 6-poles

motors (50Hz) is 1000 r/min.

1500 rpm

Depends on the motor.

F05

Motor rated voltage.

V

Depends on the motor.

F11

Overload detection level.

A

Set manually same value than

P03.

P02

Motor rated power (kW).

kW

Depends on the motor.

P03

Motor rated current.

A

Depends on the motor.

8.3 Auto tuning procedure

After inverter initialization and motor parameters setting, an auto tuning has to be performed. Auto tuning will get

special data from the motor like no-load current (P06), stator resistance (P07), stator inductance (P08) and slip

frequency (P12).

In order to perform an auto tuning follows below step by step procedure:

1.

Please set the functions described in the table 9.1 and 9.2.

2. Set function P04 to 3 and press SET.

3. Give RUN command to the inverter from the lift controller (normally INSPECTION mode). Keep the RUN

command until inverter indicates that the procedure has been finished. At this point, the main contactors will be

closed and current will flow through the motor producing some acoustic noise. This procedure will take some

seconds. After this auto tuning procedure is finished.

If during the procedure inverter trips Er7 make sure that setting specified in table 9.1 and 9.2 is correctly set. Make

sure as well of the connection recommended on chapter 5. Connections. If too high no-load current is recognized, try

auto tuning mode 2 (P04=2).

After that, please give RUN command from the lift controller (for example in INSPECTION), and check that motor is

turning without any problem. Check that the output current has reasonable value. By a reasonable value it is

understood below rated current (empty car going down for example).

TP-A1-LM2: PRG > 3 > 2 [6/6]

TP-E1U: 4_17

9. Setting the speed profile

The setting of the speed profile includes:

Travelling speed

Acceleration and deceleration times (s)

S curves (%)

For the rated speed, each intermediate speed and creep speed the acceleration, deceleration times and S curves can

be set independently. Acceleration and deceleration times are referred to maximum speed (F03), in other words, the