070.750-IOM2 (JAN 21)

Page 7

HPS 273 ROTARY SCREW COMPRESSOR

INSTALLATION - OPERATION - MAINTENANCE

Balance piston

The high pressure compressors are equipped with balance

piston assemblies to reduce load on the axial bearings. Oil

pressure is regulated by a modulating pressure regulating

valve and provides the force, and as a result, must remain

as specified by CoolWare for specific operating conditions.

Shaft seal

The compressor shaft seal is a single-face balanced type

with a spring-loaded, silicon carbide stationary hardened

surface riding against a rotating seat. Carbon and graph-

ite are added to both surfaces to provide self-lubrication.

During operation it is vented to low pressure to provide

extended life.

Motor mount

The HPS 273 series compressor is a foot mounted, open

drive model that can pair with an electric, engine, or

turbine drive.

Design limits

Use CoolWare to determine the limits for a specific ap

-

plication.

Notes for design limits:

1. CR = Compression Ratio. Absolute discharge pressure

divided by absolute suction pressure.

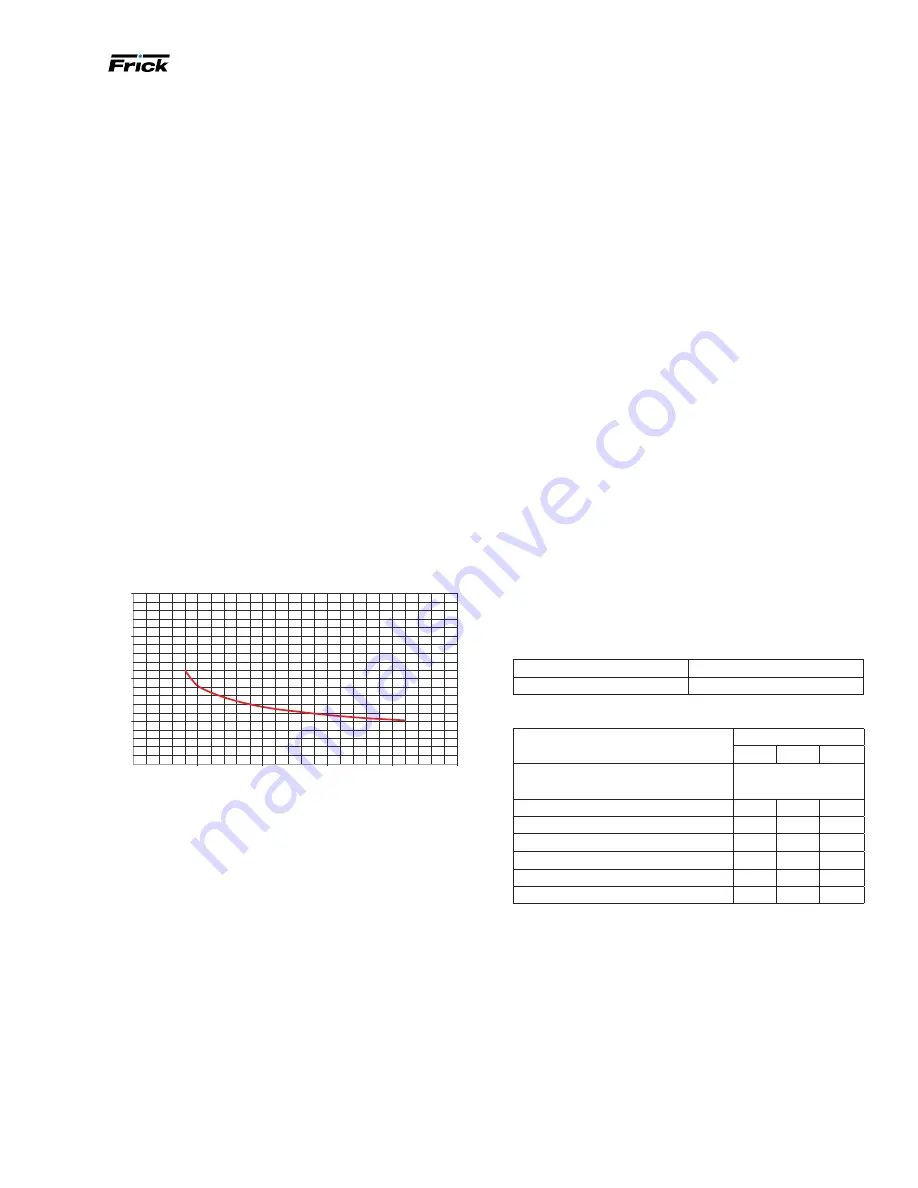

Figure 4: HPS 273 viscosity requirement as function

of speed

2. Maximum discharge temperature depends on oil type

used - normally 150°C (300°F). Refer to

160.802-SPC,

Compressor Oil Specifications

for more detail.

3.

If oil flow is more than 1.5% of swept volume and the

turndown is more than 3, regulate the main oil flow.

Turndown is the actual maximum speed/minimum

speed. CoolWare calculates the oil flow in

Lpm. See

4. The UNISAB and Quantum panels have several lay-

ers of control functions to secure reliable operation.

Depending on many operating conditions, they unload

the slide valve and reduce or increase speed to keep

the compressor running in a safe way. Only as a last

resort do they initiate an alarm and ultimately stop the

compressor.

This is particularly true for the HPS 273 compressor

models on applications with high suction pressure, like

fuel gas boosting. The concern is that the high internal

thread pressure may lead to excessive rotor deflection

and unwanted contact with the rotor housing. For this

reason, proper calibration of the slide valve and slide

stop is essential.

Note:

For 1.3 to 1.96 and 1.7 to 3.0 Vi range machines, the

main oil injection occurs at lower Vi port locations

than compressors operating with the 2.2 to 5.0 Vi

range. This means the UNISAB and Quantum use

lower values for the safeties.

5. In CO

2

applications using miscible oil types POE and

PAG, it is extremely critical to keep water content to

the lowest possible - down to 10 ppm is the goal. The

installation must have large filter dryers with replace

-

able elements that you can effectively service and

vacuum dry before putting back into service.

6. If the temperature difference becomes greater than or

equal to 180°F (355 K) between suction and discharge,

unload the slide valve immediately.

7. The minimum discharge temperature must be a mini-

mum 30°F difference above the maximum dewpoint of

the discharge gases. This applies to part load

conditions and full load operation.

Vibration and sound data

The rotors balance grade is G 2.5 according to

ISO 1940

.

The male rotor drive end of the HPS 273 compressor is

keyless.

Effective vibration velocity must not exceed 8 mm/s RMS

(0.32 in./s) anywhere on the compressor. Alarm level is 12

mm/s RMS (0.47 in./s).

Table 3: Number of rotor lobes

Male rotor lobes

Female rotor lobes

6

8

Table 4: Critical frequencies

Driver speed, rpm

3000 3600 4200

Exiting member/event

Main exciting fre-

quencies (Hz)

Male rotor, rotational, first order

50

60

72

Male rotor, rotational, second order 100

120

144

Female rotor, rotational, first

37.5

45

54

Female rotor, rotational, second

75

90

108

Discharge gas pulsation, first

300

360

432

Discharge gas pulsation, second

600

720

864

Vibration level on the package can be higher, especially

on piping elements, and when the natural frequency of an

element falls together with one of the exciting frequen-

cies. If the vibration level gets too high, a skip frequency

function in the control system activates. After activating,

the motor runs through the critical speed very fast, not

causing any continuously high vibration.

Shaft speed, rpm

1000

20

15

10

5

0

0

2000

3000

4000

5000

Vis

cosity Min., cst