4.1

With the air system fully charged, make

one full brake application and note the air

pressure reading on the primary air

gauge.

4.2

Further reduce air pressure using moder-

ate brake applications, then run the en-

gine at governed rpm.

4.3

Note the time that the pressure reaches

the previously noted reading on the pri-

mary air gauge, then note the time that

the air pressure reaches cut-out pressure.

4.4

If it takes longer than 30 seconds to reach

cut-out pressure after the primary air

gauge passes the previously noted pres-

sure (noted after one full brake applica-

tion), eliminate any leaks or replace the air

compressor before operating the vehicle.

5.

Check air leakage in the system.

5.1

With the parking brake applied, the trans-

mission out of gear, and the air system

fully charged, release the service brakes

and shut down the engine.

5.2

Wait one minute and note the air pressure

drop in psi (kPa) per minute from the pri-

mary air reservoir.

If the pressure drop exceeds the limits

shown in

Table 11.1

, eliminate any leaks

before operating the vehicle.

6.

Check the air pressure reserve.

With the engine still off, make one full brake ap-

plication and observe the pressure drop on the

primary air gauge. If pressure drops more than

25 psi (172 kPa), eliminate any leaks before op-

erating the vehicle.

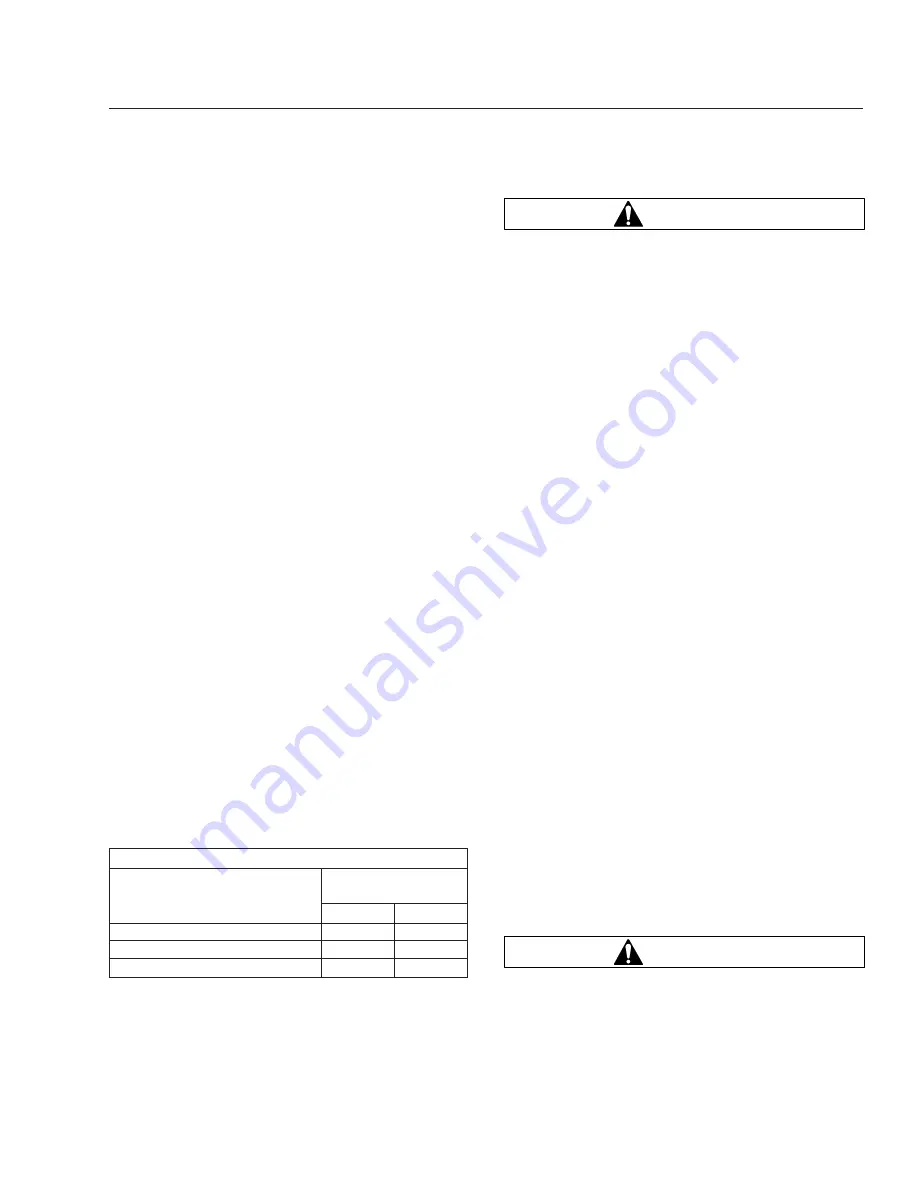

Maximum Allowable Air Leakage

Description

Pressure Drop:

psi (kPa) Per Minute

Released

Applied

Truck or Tractor Only

2 (14)

3 (21)

Truck or Tractor w/Single Trailer

3 (21)

4 (28)

Truck or Tractor w/Two Trailers

5 (34)

6 (41)

Table 11.1, Maximum Allowable Air Leakage

WARNING

When cleaning windshields and windows, always

stand on the ground or on a secure ladder or

platform. Use a long-handled window cleaner. Do

not use the cab steps, tires, fenders, fuel tanks,

engine, or under-hood components to access the

windshield or windows. Doing so could cause a

fall and result in an injury.

7.

Inspect the mirrors, window glass, and wind-

shield for cracks or other damage.

8.

Ensure that the horn, windshield wipers, and

windshield washers are operating properly.

These devices must be in good working order for

safe vehicle operation.

9.

Ensure the heater and defroster are operating

properly.

10. Check the operation of all interior lights.

10.1

Turn on the headlights and leave them on.

Ensure all equipped gauge bulbs illumi-

nate in the dash message center.

10.2

Ensure all equipped driver control

switches illuminate.

10.3

Ensure both turn signal indicator bulbs

illuminate in the dash message center

when the turn signal switch is activated.

11. Check the operation of all exterior lights. See

Fig. 11.8

.

11.1

Activate the high-beam headlights and

hazard warning lights.

11.2

Exit the cab and check that all exterior

lights and reflectors are clean and intact.

11.3

Check that the brake lights, taillights,

headlights, turn signals, marker lights,

identification lights, and clearance lights

are working properly.

12. Inspect the seat belts and tether belts.

WARNING

Inspect and maintain seat belts. When any part of

a seat belt system needs replacement, the entire

seat belt must be replaced, both retractor and

buckle side. Any time a vehicle is involved in an

accident, and the seat belt system was in use,

Pretrip and Post-Trip Inspections and Maintenance

11.8