18

WWW.FORNEYIND.COM

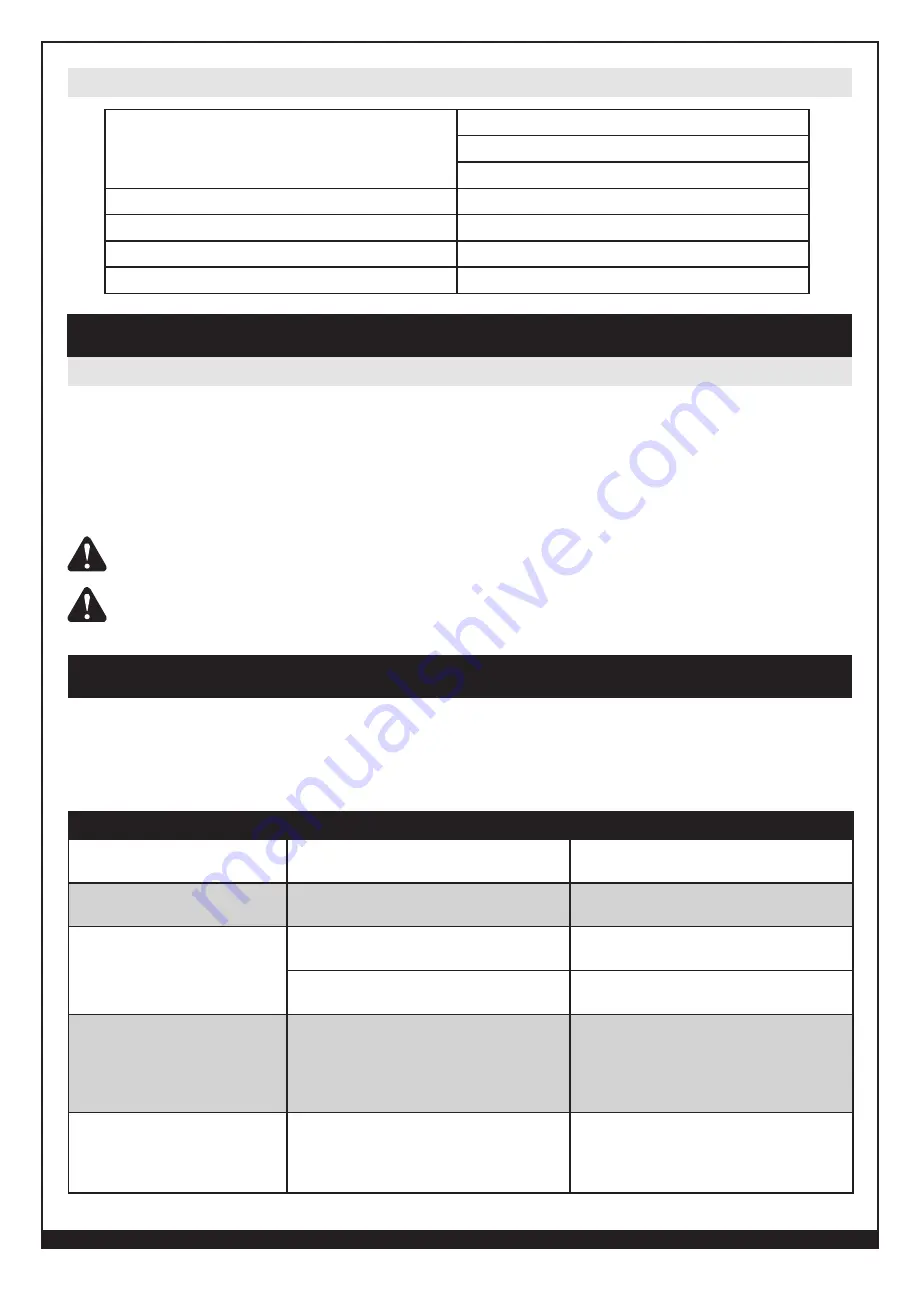

A Good Starting Point for Aluminum TIG

Amperage

< 1/8 “ = 140 MAX

1/8 “ – 3 /16” = 170 MAX

1 /4” + = 200 MAX

6a AC Freq

90 HZ

6b AC Balance

70 % EN

6c PULSE (HZ)

1

6d PULSE ( % ON)

50%

General Maintenance

This welder has been engineered to need minimal service providing that a few very simple steps are taken to properly

maintain it.

1. Replace INPUT POWER CABLE, ground cable, ground clamp, or torch/electrode cable when damaged or worn.

2. Avoid directing grinding particles towards the welder. These conductive particles can build up inside the machine and

cause severe damage.

3. Periodically clean dust, dirt, grease, etc. from your welder. Every six months or as necessary, remove the side panels

from the welder and use compressed air to blow out any dust and dirt that may have accumulated inside the welder.

WARNING: DISCONNECT FROM POWER SOURCE WHEN CARRYING OUT THIS OPERATION.

4. Check all cables periodically. They must be in good condition and not cracked.

WARNING: ELECTRIC SHOCK CAN KILL!

Be aware that the POWER SWITCH, when OFF, does not remove

power from all internal circuitry in the welder. To reduce the risk of electric shock, always unplug the welder from its AC

power source and wait several minutes for electrical energy to discharge before removing side panels.

The following is a troubleshooting table provided to help you determine a possible remedy when you are

having a problem with your welder.

This table does not provide all possible solutions, only those possibilities considered likely to be common

faults.

PROBLEM

POSSIBLE CAUSE

POSSIBLE SOLUTION

All LEDs OFF.

No input power.

Connect machine to proper input power

source.

No output power, Fan not

operating.

POWER SWITCH is OFF.

Ensure POWER SWITCH (rear) is in the ON

position.

FAULT CODE F01 DISPLAYED.

Exceeded duty cycle; thermal protector

engaged.

Verify that circuit breaker has not been tripped

in your main power panel. Reset if needed.

POWER SWITCH is OFF.

Ensure POWER SWITCH (rear) is in the ON

position.

FAULT CODE F02 DISPLAYED.

No voltage or incorrect voltage supplied to

welder.

Make sure the machine is plugged in. Check

the status of your INPUT VOLTAGE INDICATOR

LED. It should be illuminated. Check the voltage

of your outlet. If it is 10% more or less than

120V or 230V, call a qualified electrician.

FAULT CODE F05 DISPLAYED.

Torch triggered before machine is ready

Torch triggered or turned on before

machine is powered on will fault. Release

torch trigger and machine will reset within

five seconds

Maintenance & Servicing

Troubleshooting