20

21

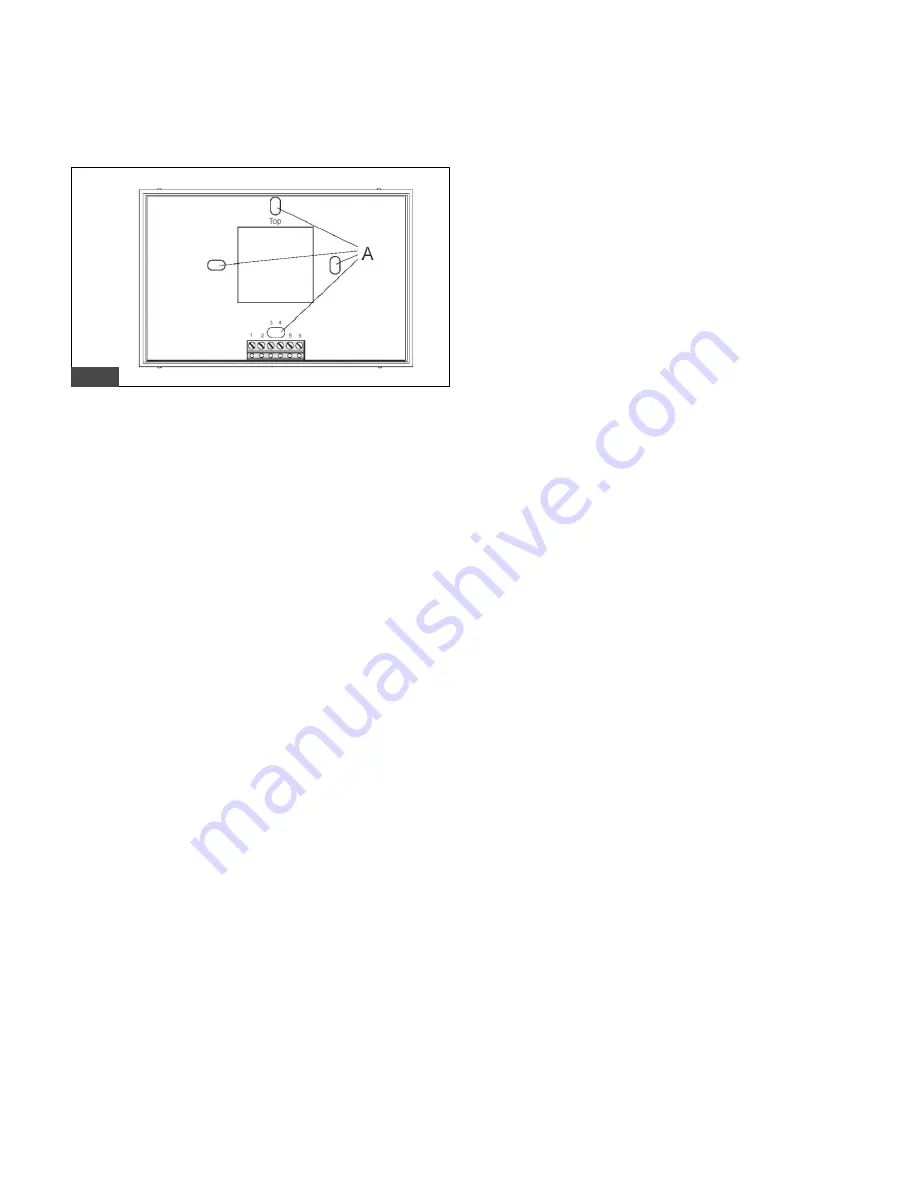

3.2.11.

“OPEN THERM”

remote control installation (option)

The heating unit can be connected to an

Open Therm

remote

control (delivered as optional equipment). Position the remote

control on an inside wall of the premises, far from heat sources or

draughts. Detach the rear part of the plastic casing (grey) from the

front one (white), by means of a screwdriver, and fix the rear part to

the wall using the holes A (pic.8).

pic. 8

WARNING

The remote control is not to be connected to the 230V power

main.

The remote control wires are not to be routed together with the

power main cables.

In order to connect the remote control, employ two-wire cables

with the following characteristics:

- max length:

40 m;

- max. impedance:

2 x 4 Ω/m

- in order to avoid interferences it is possible to implement interla-

ced wires or with a sheath.

An electronic board, code 0SCHEREM00 is provided with the

remote control kit, and it to be used to connect the remote control

to the boiler.

Refer to the instruction delivered with the electronic board, code

0SCHEREM00, for its installation.

The connection of the remote control to the heating units to be

implemented by connecting position 1 and 2 of the remote control

to the OT-BUS 06 terminal board of the 0SCHEREM00 board (see

electric layout charts). The OT-BUS 06 terminal board is protected

against false polarity, that is the connections can be switched.

Now close the remote control.

WARNING

When connecting the remote control, selector 11 is to be set

to the COMFORT � position, and the programmable timer,

when available, has to have both channels, 1 and 2, program-

med as permanently ON (see 1.2.3 paragraph).

3.2.12. External probe installation

The heating unit can be connected to an external probe for ou-

tdoor temperature measurement (standard for BV and RV models,

as option for B and R models), and “sliding temperature” function

operation (see 1.2.2.3 paragraph)

Refer to the heating unit layout charts when choosing the type

of external probe.

The external probe wires are NOT to be routed together with

the power main cables.

Position the external probe on an outside wall facing North – North

/ East.

Do not install the probe in the windows areas, near ventilation

openings or heat sources.

In order to assure correct heating unit operation, employ only

manufacturer supplied probes.

3.3. Filling up the heating system

When all system connections are performed, the CH circuit can be

filled.

The procedure is to be carefully performed, following the steps

below indicated:

- open all radiator air purging valves and the automatic relief valves

on the heating unit;

- remove the front panel (for model R), or its lower part (for models

B), of the heating unit by pulling it toward the outside;

- turn the loading tap counter-clockwise in order to allow water

into the system;

- close the radiator air purging valves as soon as water comes out;

- check the gauge to show a pressure of 1-1,3 bars;

- close the loading tap and open all radiator air purging valves

again;

- switch on the heating unit and allow the system to reach working

temperature, then switch it off and repeat the air bleeding proce-

dure;

- allow the system to cool down and check the water pressure to

be 1-1,3 bars.

3.4. Starting up the heating unit

3.4.1. Preliminary checks

Prior to starting up the heating unit perform the following checks:

- the flue gas discharge pipe and the air intake pipe are installed

correctly: while the heating unit is working, no leakage of

combustion products from any of the seals is to be detected;

- the power supply voltage is 230 V - 50 Hz;

- the system is correctly filled with water (water pressure gauge

reading 1-1,3 bar);

- any cut-off valves in the CH and DHW systems are open;

- the fuel supply tap is open;

- the master switch is ON;

- the safety valve is not blocked;

- no water leaks are detected;

3.4.2. Switching on and off

For instructions on how to switch the heating unit on and off, refer

to the “Instructions for the user”.

3.4.3. Burner adjustment

After starting up the heating unit it is necessary to adjust the bur-

ner (see paragraph 4.4), checking that:

- fuel oil pressure;

- CO

2

concentration;

- Bacharach index;

- flue gas temperature;

are in compliance with the values indicated in the technical data

chart (see4.4 paragraph).