444 9160 / 444 9180 / 442 9020

25

E 219 GB - Issue 1

When the columns have been erected, check that the measurements correspond with the datasheet.

Align the columns with the aid of a spirited level.

They should tilt slightly outwards after dowelling.

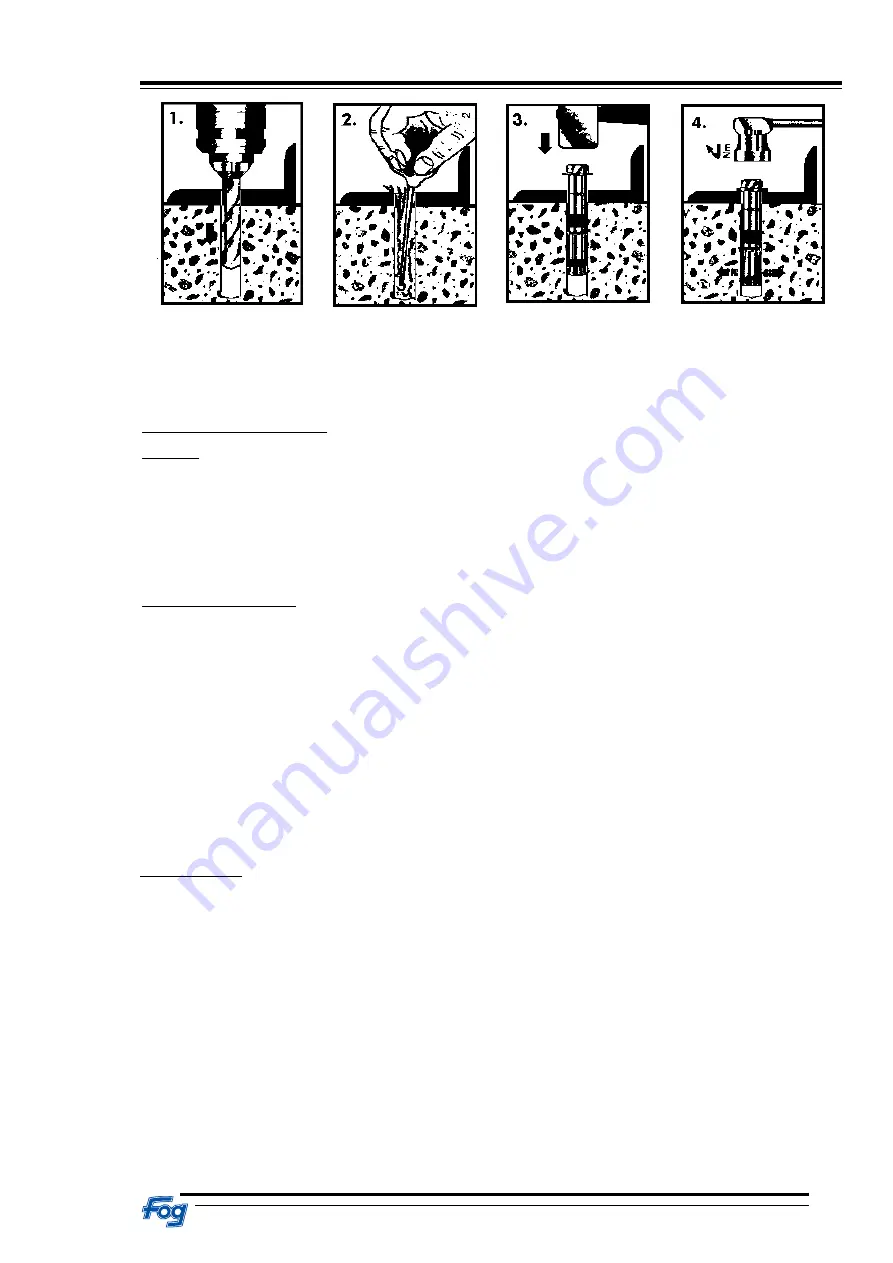

Using a masonry drill (nominal drill diameter = 24 mm, maximum diameter = 24,55 mm), place the drill bit over

the drill holes of the base plate and drill approx 200 mm deep into the concrete base.

Regulations for dowelling

General

The dowel may only be used as a standard unit as delivered for its fixing purpose. Individual parts must not be

replaced.

The assembly of the dowel to be anchored must be carried out in accordance with section 3.1 of the construction

drawings and the assembly instructions of the company. Before placing the dowels, the concrete quality of the

foundation where the dowel is to be anchored must be checked. It must not be below the concrete quality

assigned to the permitted load and not above B55.

Drill hole preparation

The position of the drill hole must be such that damage to the reinforcement is avoided.

The hole should be drilled with a hard metal hammer drill at right angles to the surface of the anchor base. The

hard metal hammer drill must comply with the stipulations in the information leaflet of the Institute for Building

Technology about “Nominal values for quality assurance for hammer drills with cutting plates from hard metal

(hard metal hammer drills) which ar used the drilling holes for dowelling connections (edition June 1977/

Amendment October 1979).

Compliance with the nominal drill values must be proven in the form of a test certificate 3.1 A to EN 10 204,

or in form of a test symbol (see information leaflet) of the Testing Guild of Builders’ drills e.V., Remscheid.

The nominal drill diameter and cutting diameter must correspond to the values in appendix 4. If he hole was

not successfully drilled, the new hole should be drilled at a distance of at least 2 x the depth of the wrong drill

hole.

The drill dust must be removed from the drill hole.

Lacing dowels

The dowel should be easily inserted by tapping with a hand hammer. The washer must touch the inserted part.

The torque values can be found in appendix 4.

If the torque value stipulated in appendix 4 cannot be achieved, then the dowel must not carry any weight.

If the threaded bolt or screw is loosened again after insertion, then the threaded bolt or screw must be screwed

in again into the thread cone by at least the measure of the thread diameter and the stipulated torque value

must be applied again.

Mounted dowels can be checked again at any time; the stipulated torque value for anchoring the dowel must

be achieved again each time.

Содержание 442 9020

Страница 13: ...444 9160 444 9180 442 9020 13 E 219 GB Issue 1 ...

Страница 14: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 14 ...

Страница 15: ...444 9160 444 9180 442 9020 15 E 219 GB Issue 1 ...

Страница 17: ...444 9160 444 9180 442 9020 17 E 219 GB Issue 1 Lifting arms for type 442 9020 ...

Страница 21: ...444 9160 444 9180 442 9020 21 E 219 GB Issue 1 ...

Страница 23: ...444 9160 444 9180 442 9020 23 E 219 GB Issue 1 ...

Страница 42: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 42 13 Electrical diagrams ...

Страница 43: ...444 9160 444 9180 442 9020 43 E 219 GB Issue 1 ...

Страница 44: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 44 ...

Страница 45: ...444 9160 444 9180 442 9020 45 E 219 GB Issue 1 14 Spare parts ...

Страница 46: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 46 ...

Страница 47: ...444 9160 444 9180 442 9020 47 E 219 GB Issue 1 ...

Страница 48: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 48 ...

Страница 49: ...444 9160 444 9180 442 9020 49 E 219 GB Issue 1 ...

Страница 50: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 50 ...

Страница 51: ...444 9160 444 9180 442 9020 51 E 219 GB Issue 1 ...

Страница 52: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 52 ...

Страница 53: ...444 9160 444 9180 442 9020 53 E 219 GB Issue 1 ...

Страница 54: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 54 ...

Страница 55: ...444 9160 444 9180 442 9020 55 E 219 GB Issue 1 ...

Страница 56: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 56 ...

Страница 57: ...444 9160 444 9180 442 9020 57 E 219 GB Issue 1 ...

Страница 58: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 58 ...

Страница 59: ...444 9160 444 9180 442 9020 59 E 219 GB Issue 1 ...

Страница 60: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 60 ...

Страница 61: ...444 9160 444 9180 442 9020 61 E 219 GB Issue 1 15 Service book for Vehicle lifts 4449160 4449180 4429020 ...

Страница 70: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 70 ...

Страница 71: ...444 9160 444 9180 442 9020 71 E 219 GB Issue 1 ...