OPERATING INSTRUCTIONS

29

Side channel blower

Version: 27222 - C

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

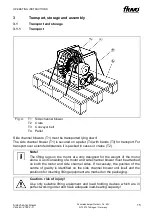

7.2.2

Lubrication and change of lubricant

Side channel blowers with standard design are only supported in the drive motor bearing.

The bearings in smaller motors are designed to last for life and have permanent grease

lubrication that cannot be relubricated. Faulty bearings must be replaced.

7.3

Repair

7.3.1

General information

Repair work must only be performed on the side channel blower after removal and in a

suitable workshop.

The following instructions will allow you to disassemble the side channel blower and

reassemble it properly with the necessary new parts.

Jobs can be performed with standard workshop tools. Special tools are not required. After

disassembly, clean all the individual parts of the side channel blower. Check the individual

parts for wear and damage. Parts that are not in flawless condition must be reworked or

replaced.

7.3.2

Preparations for disassembly

Before starting disassembly, the side channel blower must be secured so that it cannot be

turned on (turn the power off). Place a warning notice on the switch cabinet!

If the system is in operation, inform the shift manager.

When performing the jobs described below, take local regulations and specific

features into consideration.

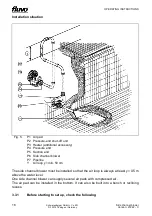

7.3.3

Disassembly / removal of the side channel blower

•

The side channel blower must have reached ambient temperature.

•

Disconnect the power supply.

•

Close the fittings (suction-end and pressure-end).

•

Unclamp the motor.

•

Disassemble any additional connections that are present.

•

Loosen the pressure and suction connections.

•

Loosen the side channel blower from the base plate.

•

Raise the side channel blower completely up.

Note!

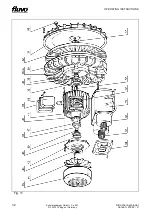

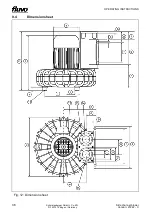

Note also the enclosed exploded drawing and spare parts list! (section 8).

In case of defects send the side channel blower in to the factory for repairs.