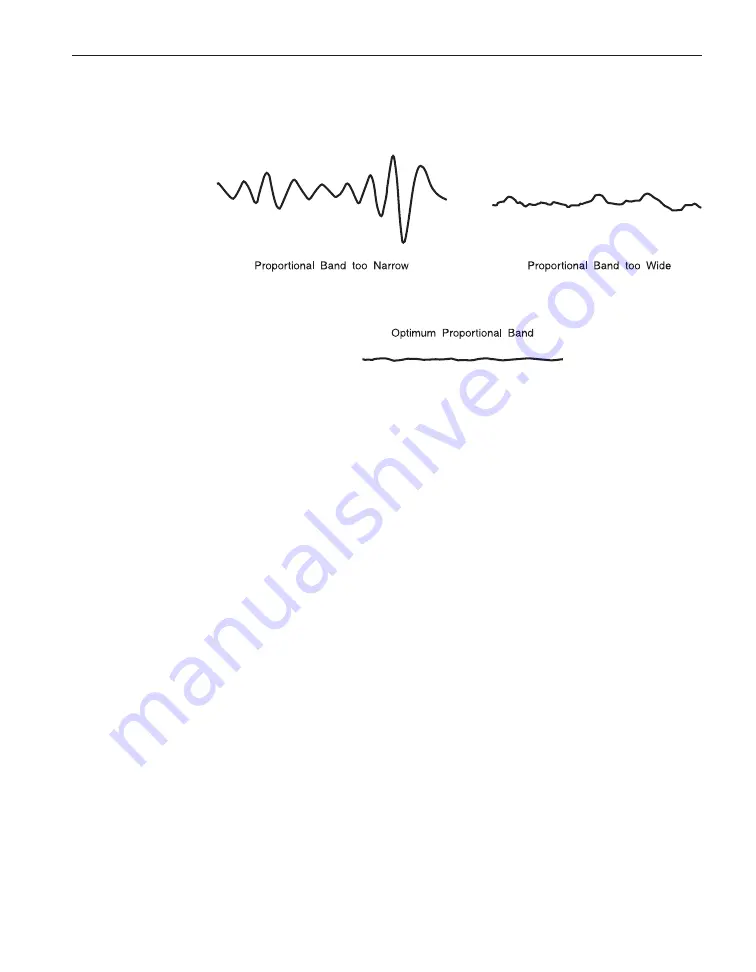

The temperature stability of the bath depends on the width of the proportional

band (see Figure 6).

If the band is too wide, the bath temperature deviates excessively from the

set-point due to varying external conditions. This is because the power output

changes very little with temperature and the controller cannot respond very

well to changing conditions or noise in the system.

If the proportional band is too narrow, the bath temperature may swing back

and forth because the controller overreacts to temperature variations.

For best control stability the proportional band must be set for the optimum

width. The optimum proportional band width depends on several factors in-

cluding fluid volume, fluid characteristics (viscosity, specific heat, thermal con-

ductivity), operating temperature, and stirring. Thus, the proportional band

width may require adjustment for best bath stability when any of these condi-

tions change. Of these, the most significant factors affecting the optimum pro-

portional band width are the fluid viscosity and thermal noise due to difference

in temperature between the fluid and ambient. The proportional band should be

wider when the fluid viscosity is higher because of the increased response time

and also when noise is greater.

The proportional band width is easily adjusted from the bath front panel. The

width may be set to discrete values in degrees C or F depending on the selected

units. The optimum proportional band width setting may be determined by

monitoring the stability with a high resolution thermometer or with the control-

ler percent output power display. Narrow the proportional band width to the

point at which the bath temperature begins to oscillate and then increase the

band width from this point to 3 or 4 times wider. Table 4 lists typical propor-

tional band settings for optimum performance with a variety of fluids at se-

lected temperatures.

47

9 Controller Operation

Proportional Band

Figure 6

Bath Temperature Fluctuation At Various Proportional Band Settings