51-7

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

3. Attach the positioner to the pre-assembled mount-

ing bracket and fasten it with two hexagon head

screws (4) and two lock washers (3). Check that the

follower pin (15) is inserted in the slot of the take-off

arm (11) and the follower arm (12) is positioned at

a right angle to the outer edge of the positioner.

4. Tighten all screws and nuts.

NOTE: A slight unsymmetrical mounting increases

the linearity deviation but does not affect the per-

formance of the device. Depending on the actua-

tor size and stroke it may be necessary to flip the

take-off arm (Figure 6) by 180

°

and attach it to the

opposite side of the stem clamp bracket (8).

Follower Pin Adjustment

The positioner follower pin must be adjusted to match

the valve stroke in the following manner:

1. Adjust the follower pin ( 10 mm) as indi-

cated on the follower arm’s embossed scale.

2. Exhaust the actuator.

3. Loosen the follower pin and shift it along the fol-

lower arm until the control marking on the feed-

back gear (Figure 3) is horizontal (points to the

center of the feedback potentiometer). Fasten the

follower pin in this position.

4. Adjust the actuator to full stroke and check the fol-

lower pin adjustment the same way as described

in step 3. As the actuator strokes, the rotation of

the feedback gear should be between the inner

control markings. If the length of rotation is outside

the control markings, adjust the follower pin far-

ther out on the feedback lever to reduce the angle

of rotation.

NOTE: Stroke the actuator carefully and ensure the

follower arm does not interfere with valve parts,

actuator or positioner. Do not adjust the follower

pin (15) too near to the slot end of the take-off arm

(11). The minimum lateral distance should be ap-

proximately 0.2-inches (5 mm) to prevent binding

of the feedback mechanism.

ROTARY ACTUATORS

Mounting the Logix 500 Series positioner

on a quarter-turn actuator (closed by spring)

The mounting of a pneumatic double-piston part-turn

valve actuator (in accordance with VDI/VDE) is described

as an example by using the following equipment:

Part-turn valve actuator: AMG Type SAF, closed by

spring

Butterfly damper: 90

°

rotary angle

Pre-assembly: Mounting block with actuator, actua-

tor with damper (damper position is adapted with the

actuator stroke)

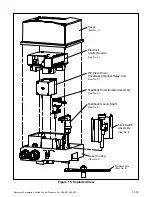

Figure 6: Mounting on a Rod Actuator (NAMUR)

1 2

3

4

5

6

7

8

9

10

17

16

12

13

14

11

15

18

1. Nut (4x)

2. Lock washer (4x)

3. Lock washer (2x)

4. Hexagon head screw (2x)

5. Actuator leg (left)

6. U-bolt (2x)

7. Stem clamp

8. Stem clamp bracket

9. Lock washer (2x)

10. Hexagon socket screw (2x)

11. Take-off arm

12. Follower arm

13. Washer

14. Nut

15. Follower pin

16. Hexagon socket screw

17. Washer

18. Mounting bracket