51-15

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

R - - -

Any sequence starting with a red light indicates that there is an operational problem with

the unit.

RGRR

25

Position Deviation - The position has exceeded user defined error band between com-

mand and position.

RYGG

26

Initializing, or LED test mode - This sequence should only be visible for 3 sequences

when powering up the unit.

RYYY

27

Hall sensor non-motion - Check to make sure the air supply is connected. This error may

be cleared by briefly pushing the Quick-Cal button, which will force the positioner to use

the parameters from the last good calibration. If the positioner still does not operate

replace the pneumatic relay assembly.

RYYR

28

Hall sensor lower position - Check to make sure the air supply is connected. This error

may be cleared by briefly pushing the Quick-Cal button, which will force the positioner to

use the parameters from the last good calibration. If the positioner still does not operate

replace the pneumatic relay assembly.

RYRY

29

Hall sensor upper position - Check to make sure the air supply is connected. This error

may be cleared by briefly pushing the Quick-Cal button, which will force the positioner to

use the parameters from the last good calibration. If the positioner still does not operate

replace the pneumatic relay assembly.

RRGG

30

1.23v reference - Bad electronic assembly, replace.

RRGR

31

12-bit A/D reference - Bad electronic assembly, replace.

RRYG

32

Temperature limit - The internal positioner temperature is currently exceeding operational

limits of -40ºF (-40ºC) or 185ºF (85ºC).

RRYY

33

Piezo voltage - Bad electronic assembly, replace.

RRYR

34

Board current high - Check internal wiring and connectors for electrical shorts, if no

shorts bad electronic assembly, replace.

RRRG

35

12-bit D/A reference - Bad electronic assembly, replace.

RRRY

36

EEprom checksum error - The checksum of the internal data has become corrupted.

Cycle power and complete a Quick-Cal if needed. Check internal data to verify correct set-

tings. If the error still occurs, bad electronic assembly, replace.

Colors

Identifier Indication and resolution

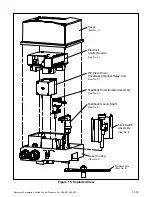

Figure 11: Limit Switch Unit

Table 9: Logix 500 Status Condition Codes (continued)