10

2.1.4

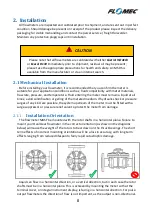

Filtration / Straining

It is recommended to fit the inlet side of your flowmeter directly to a strainer of

appropriate pipe size and mesh size. The minimum mesh size as shown in the specifications

section of this manual should be adhered to where ever possible. When metering medium

or high viscosity fluids it may be necessary to use a strainer one pipe size larger than the

flowmeter nominal size, in order to limit the pressure drop across the strainer basket and

maintain strainer efficiency

(i.e. a 1.5” strainer on a 1” meter).

In systems where there is potential for hard particles of any size, the filtration levels of the

system should be improved so as to eliminate the flow of hard particles through the meter.

While soft particles may pass through the rotating meter components without damage (if

they are small enough) hard particles are abrasive and will always cause rotor and bearing

damage regardless of size.

2.1.5

Pipe Connections

When installing a flowmeter, it is important that no upstream pipe join between the

flowmeter and the strainer are sealed using PTFE sealing tape. Lose pieces of PTFE tape

are common causes of failure in new meter installations due to the tendency to wrap

around the rotating components inside the meter. It is recommended that the sealing of

pipe joins should be done with a sealing paste or liquid

(such as Loctite® 565 thread

sealant paste).

Flanged connections should be made using gaskets and bolting suitable for the metered

liquid and the system pressure; flowmeters fitted with stainless steel flanges may be

installed using metallic gaskets and high strength bolting if required. For meters fitted

with Aluminium flanges it is only suitable to make pipe connections in accordance with

the relevant flange standard requirements for cast iron flanges; gaskets according to

ASME B16.5 Annex C gasket group 1a are recommended, and only low strength or

intermediate strength bolting may be used.

For all flanged pipe connections to flowmeters it is essential that flange faces are well

aligned and closely fitting.

Flange bolts in Aluminium flanges should never be tightened to torque

values greater than 110ft.lb (150Nm)

CAUTION

Содержание Oval Gear

Страница 1: ...Industrial Oval Gear Flowmeters with pulse output or electronic display Operation Manual ...

Страница 30: ...30 Applicable Models 080 080E 100 100E Applicable Models 025P ...

Страница 34: ...34 Notes ...

Страница 35: ...35 Notes ...