Fläkt Woods

3099 US 03.02

21

Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger

TECHNICAL HANDBOOK

1 Speed controller

2 Differential pressure switch.

3 Control signal

Control

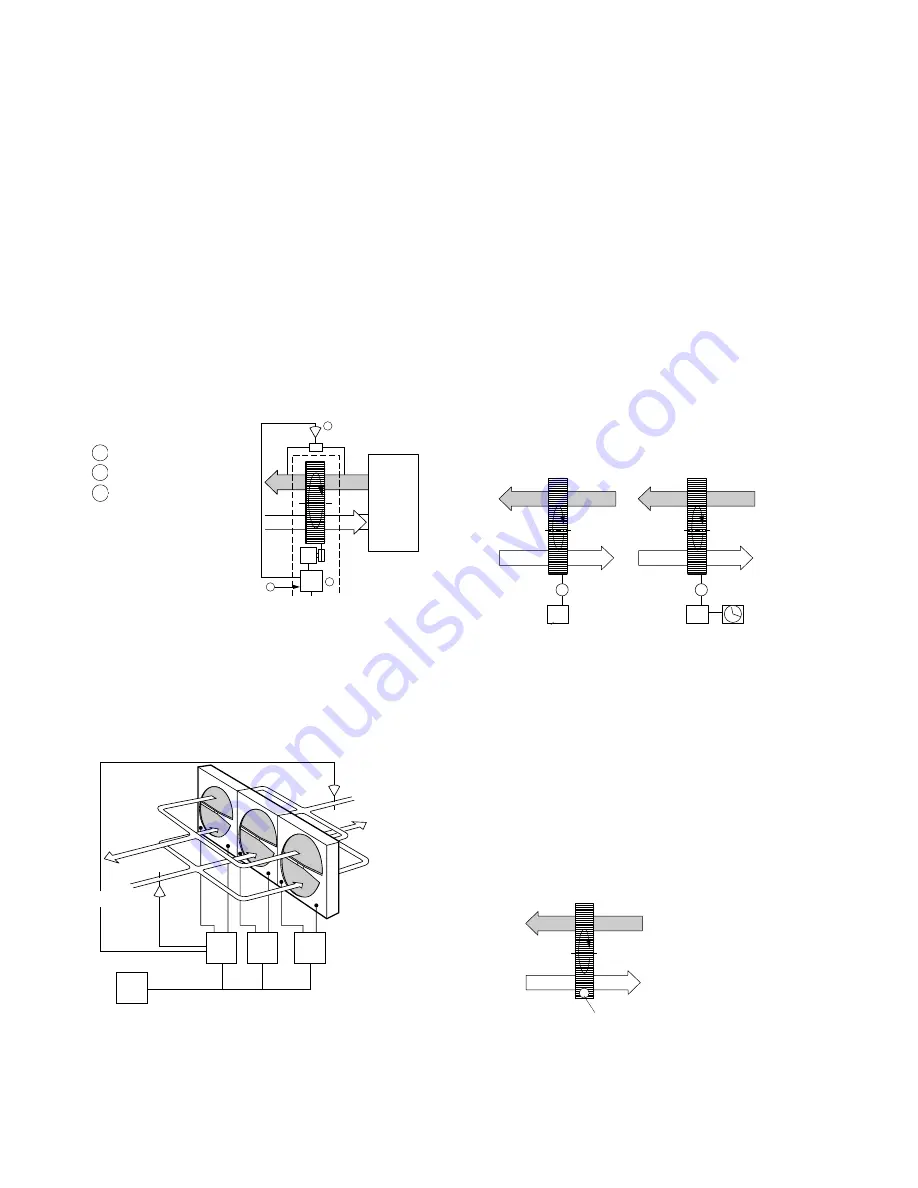

Example 7. Purging operation

Purging operation should be employed when the heat

exchanger rotor is stationary for an extended period of

time in an environment in which the supply or exhaust

air contains dust that may cause clogging.

For the ECONOVENT with variable speed, no time-

switch need be employed. Purging operation is integrated

into the speed controller. The function is switched on

automatically when the rotor is stationary. A timeswitch

(SU) with 24-hour dial is used for the ECONOVENT

with constant speed, and this starts the rotor and runs it

at maximum speed for 0.5–1 hour per 24 hours. Any

dust that may have settled in the rotor passages will then

be blown away by the air flow which is continually

reversed through the rotor. A filter should always be

installed in systems in which the dust is likely to cause

deposits (see page 16).

Variable speed Constant speed

M

RC

RPM

Reglersignal

M

K

SU

Fig. 19

Control signal,

heat recovery

Temperature limit for the drive motor

To ensure effective cooling of the drive motor located

inside the casing, the temperature in the motor compart-

ment should always be lower than +100 °F.

In systems in which the supply or exhaust air is at a

higher temperature than +100 °F, the heat exchanger

should be installed so that the leakage flow is from the

cooler air stream to the warmer air stream. This is achiev-

ed by p1 > p2 and p2 > p4 as shown in Fig. 20 below. If

the supply and exhaust air are both at temperatures above

+100 °F, the motor compartment should be cooled by

means of a separate fan.

As an alternative, the heat exchanger can be supplied

with the drive motor located outside the casing.

p3

p1

p4

p2

Motor

”Varmt” luftflöde

t

≥

+40

°

C

”Kallt” luftflöde

t

≤

+40

°

C

Warmer air at

t

≥

+100 °F

Cooler air at

t

≤

+100 °F

Motor

Fig. 20

Example 5. Frosting monitor

Variable speed: The frosting monitor is used for indicat-

ing frosting in the rotor at very low outdoor temperatures

and high humidity of the exhaust air. If the pressure drop

across the rotor exceeds the value preset on differential

pressure switch 2, the rotor speed will be reduced if the

heat exchanger is running at variable speed.

Constant speed: In the case of a constant-speed heat

exchanger, the rotor is defrosted by the supply air being

by-passed across the rotor via a damper or by the supply

air fan being stopped. The differential pressure switch

indicates when the damper should be opened or when

the fan should be stopped.

Caution. No frosting is permissible in a composite

rotor.

Example 6. Parallel operation

If several rotary heat exchangers are included in a given

air handling system and are thus to be controlled simulta-

neously, each heat exchanger must have its own speed

controller and sensor for the speed detector. On the other

hand, the control signals from the control unit (RC) and

summer case sensors can be connected to only one speed

controller, from which the others are supplied.

Rum

RC

RPM

DM

1

3

2

RC

RPM

RC

RPM

RC

RPM

RC

Frånluft

Tilluft

Fig. 18

Room

Supply air

Exhaust air

Fig. 17

RC = Control unit

RC

RPM

= Speed controller