23

22

SPECIALIZED

HEALTHY

AIR SOLUTIONS

SPECIALIZED

HEALTHY

AIR SOLUTIONS

OWNER’S MANUAL

OWNER’S MANUAL

ASCENDANT

™

ASCENDANT

™

SPECIALIZED

HEALTHY

AIR SOLUTIONS

OWNER’S MANUAL

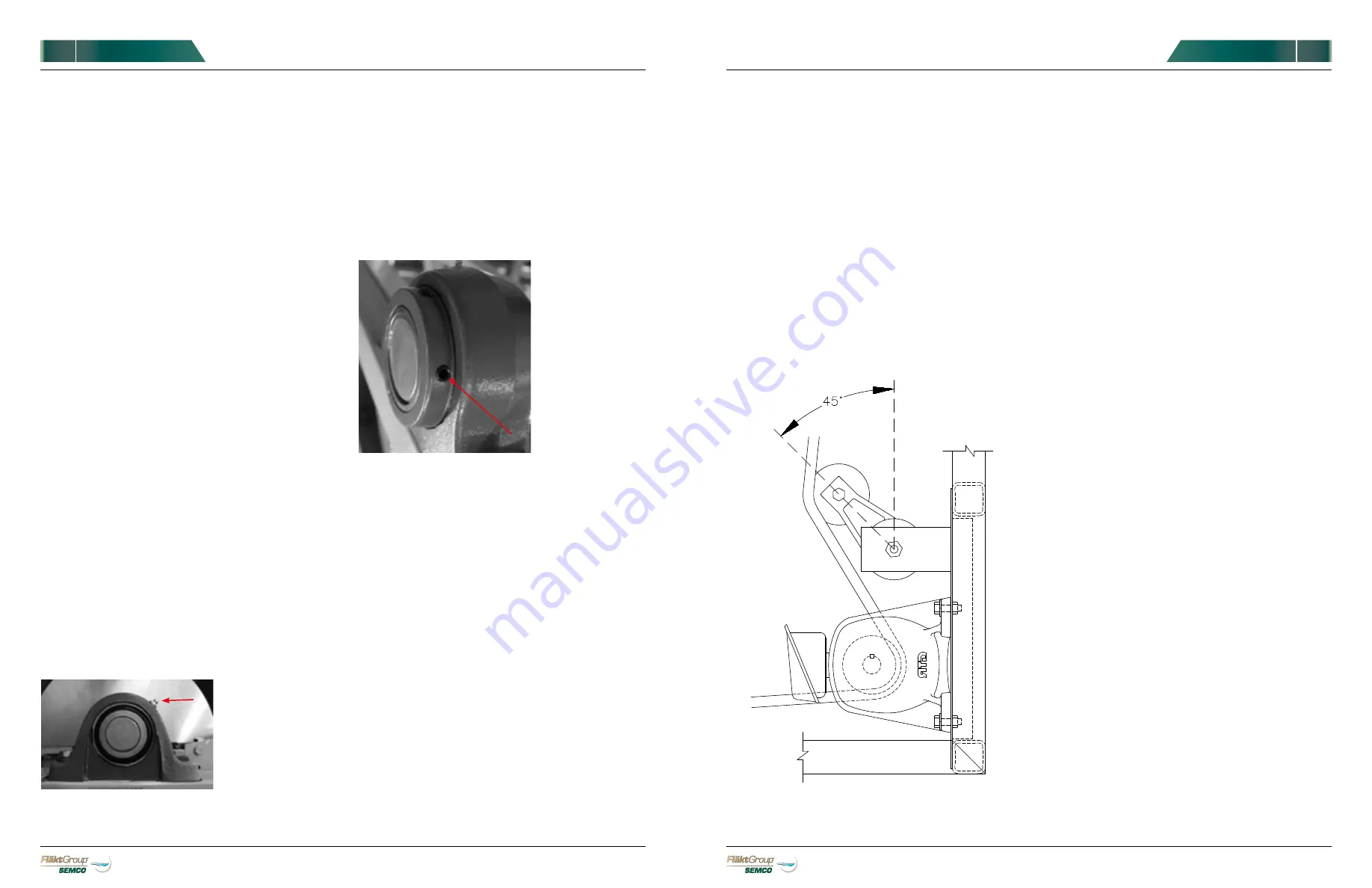

FIGURE 31.

Detail of TE-1567 R0 Idler

VARIABLE FREQUENCY CONTROLLER

1)

The variable frequency controller is cooled by

air flowing through the heat sink slots. The

slots must never be allowed to become

obstructed with dirt or foreign material.

Periodically check and clean the heat sink

slots with compressed air or a vacuum.

Airflow must never be restricted in any way.

2)

Check and clean the variable frequency

controller annually.

MEDIA CLEANING

Semi-annually, or more frequently if pressure drop

across the wheel increases at a given airflow, clean

wheel media by air blowing at 100 psi while using a

vacuum or other device to collect any dust or debris

that may exit the other side. Extra care should be

taken to ensure that the air nozzle or vacuum/other

device does not touch or damage the rotor surface.

SEALS

Seals should be checked to ensure they remain in

gentle contact with the wheel after the first month of

operation, and every 3 months thereafter.

NOTE:

If seals give any sign of binding the rotor, they should

be adjusted immediately.

Adjustment of the seals is simply done by loosening

the screws holding the seal clips in place, adjusting the

seal so it just contacts the surface of the wheel/rim,

and then re-tightening the screws.

holding the bracket to the perimeter, correct the

position, laterally and/or along the perimeter, so the

teeth now mesh, and reattach the bracket using #10 x

¾” tek screws.

CHAIN TENSION DETAIL

If the chain is excessively tight, chain damage and

gear motor failure may result. If the chain is too loose,

the chain may slip off the wheel sprocket(s). A good

rule of thumb for amount of slack is 2 to 4 percent of

the distance between the idler and the point where the

chain connects with the wheel.

The tensioner should be positioned so that after final

tensioning it is approximately at a 45 degree angle as

shown on

FIGURE 31

. Too little tension will limit the

effectiveness of the tensioner and too much may cause

premature chain failure.

TENSIONER ADJUSTMENT

1)

Loosen the tensioner by accessing the

mounting bolt from the back side of the

mounting bracket.

2)

Adjust the tensioner base by using a wrench

on the adjusting nut to load the tension spring.

3)

Tighten until chain has proper amount of

slack and preload tensioner spring. Utilize

tick marks on the tensioning arm and base

as a guide. After final tensioning the tensioner

should be able to move one full tick mark

when pulled to compress the spring (removing

chain tension).

SPECIALIZED

HEALTHY

AIR SOLUTIONS

OWNER’S MANUAL

MAINTENANCE: SYSTEM

The system enclosure requires very little maintenance

since it is constructed of strong, weather-resistant

materials. Equipment contained within the enclosure

requires regular maintenance to keep the system

operating smoothly. You will find maintenance

instructions for every component in this section.

•

Inspect the enclosure periodically:

•

Check for air leaks in the casing

•

Ensure modules remain level

•

Make sure that doors do not bind

•

Check around all penetrations and roof joints to be

sure that seals remain tight and do not leak

MAINTENANCE: WHEEL

ROTOR BEARING

The rotor bearing’s anticipated average life is 20 years.

The bearing was greased prior to shipment. However,

lubrication just prior to start-up is recommended.

RECOMMENDED LUBRICATION

The bearing’s lubrication cycle depends upon the range

of temperatures normally experienced by the unit 24

hours a day. For a typical temperature range of -20°F

to 130°F, lubrication every 6 months is adequate. If

higher temperatures (130° to 170°F) are experienced,

lubrication every 3 months is recommended. For

environments with temperatures above 170°F, consult

FläktGroup SEMCO.

Grease should be pumped into the 2 bearing grease

points - one located on each side of the rotor. (See

FIGURE 29

) A high grade NLGI No. 2 grease is

recommended.

NOTE:

If a rotor bearing requires

replacement, contact FläktGroup SEMCO for detailed

instructions.

FIGURE 29.

Grease

should be pumped

into two rotor bearing

grease points, one

located on each side

of the rotor. Lubrication

frequency depends

upon operating

temperatures normally

experienced around the

rotor.

FIGURE 30.

The

bearing set screws,

one on each side of

the rotor, should be

checked for tightness

every six months.

The bearing bolts normally require checking at start-up

only. The bearing bolts should be torqued to 50 ft-lbs.

BEARING SET SCREWS

1)

The bearing set screws should be checked

periodically for tightness. A bearing set screw

is located on each side of the rotor (See

FIGURE 30

).

RECOMMENDED CHECKING FREQUENCY

–

Bearing set screws should be checked at start-

up, one month after start-up, then every 6 months

thereafter.

2)

The bearing set screws should be torqued to 15 ft-lbs.

MOTOR

The motor has deep grooved, double-shielded bearings

with sufficient lubricant packed into the bearings by the

manufacturer for “life lubrication.” The initial lubricant

is supplemented by a supply packed into larger

reservoirs in the end shield at the time of assembly. No

grease fittings are provided as the initial lubrication is

adequate for up to 10 years of operation under normal

conditions. No lubrication is required.

WHEEL DRIVE SYSTEM

The chain and sprockets should be checked

periodically for wear and correct chain tension after

start-up and semi-annually thereafter. Although the

Ascendant wheel rotates at low speeds – less than

25 revolutions per hour – unnecessary wear can still

result from misalignment or improper tensioning.

DRIVE SYSTEM ALIGNMENT

At startup, observe the chain as the wheel rotates.

The chain should mesh with the teeth on the wheel

perimeter. If the teeth do not mesh, remove the screws