17

16

SPECIALIZED

HEALTHY

AIR SOLUTIONS

SPECIALIZED

HEALTHY

AIR SOLUTIONS

OWNER’S MANUAL

OWNER’S MANUAL

ASCENDANT

™

ASCENDANT

™

SPECIALIZED

HEALTHY

AIR SOLUTIONS

OWNER’S MANUAL

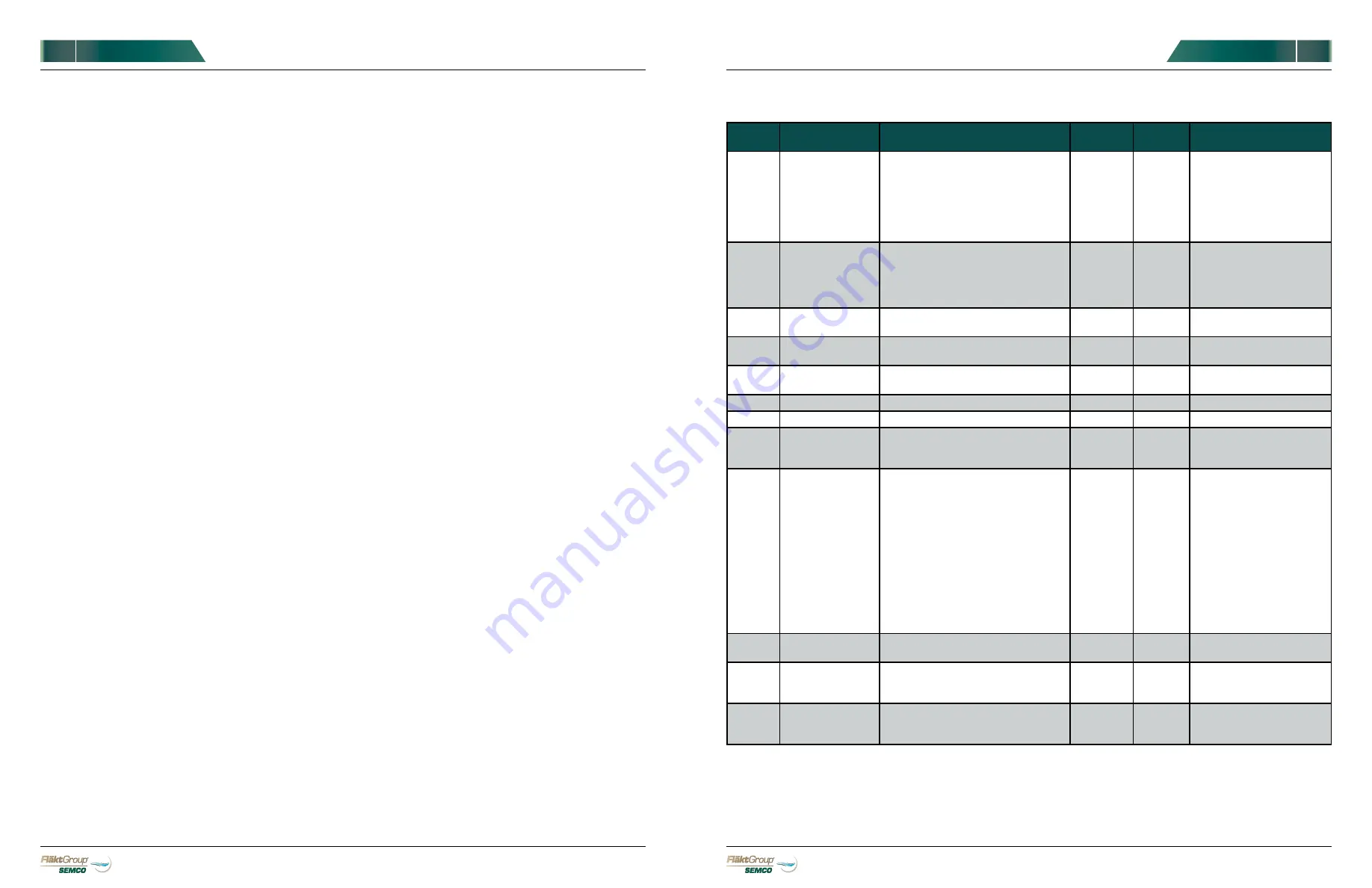

PARAM.

TITLE

FUNCTION

OPTIONS

DEFAULT

SETTING

SEMCO

SETTING

COMMENTS

B1-01

Frequency

Reference

Selection 1

0: Operator - Digital preset speed d1-

01 to d1-17.

1: Terminals - Analog input terminal A1

or A2.

2: MEMOBUS communications

3: Option PCB

4: Pulse Input (Terminal RP)

1

1

Selects the frequency

reference input source.

B1-02

Run Command

Selection 1

0: Operator - RUN and STOP keys on

the digital operator.

1: Digital input terminals

2: MEMOBUS communications

3: Option PCB

1

1

Selects the run command

input source.

B1-04

Reverse Operation

Selection

0: Reverse enabled.

1: Reverse disabled.

0

1

Permits or prohibits reverse

operation.

B1-07

Local / Remote

Run

0: Run command must be cycled

1: Continue running

0

1

Drives run if run command

is active in new controller

B1-17

Run Command at

Power Up

0: Run command must be cycled

1: Run command issued

0

1

Drive runs if run command

is active at power up

C1-01

Acceleration Time

0.0 to 6000.0

10

60

Acceleration time

C1-02

Deceleration Time

0.0 to 6000.0

10

60

Deceleration time

C4-01

Torque

Compensation Gain

0.00 to 2.50

1

0

Compensates for added

load by increasing output

voltage.

C6-02

Carrier Frequency

Selection

1 : 2.0 kHz

2 : 5.0 kHz

3 : 8.0 kHz

4 : 10.0 kHz

5 : 12.5 kHz

6 : 15.0 kHz

7 : Swing PWM1 (Audible sound 1)

8 : Swing PWM2 (Audible sound 2)

9 : Swing PWM3 (Audible sound 3)

A : Swing PWM4 (Audible sound 4)

B to E: No setting possible

F : User defined (determined by C6-03

through C6-05)

3

1

Lower carrier frequencies

increase torque and audible

noise.

E1-03

V/f Pattern

Selection

0 to FF

F

F

Allows custom voltage

frequency curve.

E2-01

Motor Rated

Current

10 to 200% of drive rated current

kVA

dependent

0.57

(208-230)

0.29 (460)

E2-03

Motor No-Load

Current

0 to [E2-01]

kVA

dependent

0.23

(208-230)

.11 (460)

Nameplate amps * 40%

Consult SEMCO

PROGRAMMING PARAMETERS

*FläktGroup SEMCO does not recommend use with motors other than those provided with the unit. Consult Yaskawa for assistance

in programming for use with other motors.

SPECIALIZED

HEALTHY

AIR SOLUTIONS

OWNER’S MANUAL

UNIT CONTROLS

PROGRAMMING PARAMETERS

PROGRAMMING THE WHEEL MOTOR VFD:

NOTE:

For most V1000 parameters, the drive must be in a

STOP

condition while programming.

1)

Press

ESC

key until left-most part of drive’s display

shows

F

.

DRV

LED will also be lit.

2)

Press

DOWN

arrow twice to display

PAr

then press

ENTER

key. (Parameters are now accessible)

3)

Using

UP/DOWN/RIGHT ARROWS

, select

parameters to be read and/or changed starting

with A1-01.

4)

If required, use

RIGHT ARROW

or

ENTER

key to

scroll to right-most digits of parameter name.

Digits will flash.

5)

Press

ENTER

key to read value.

6)

Using

UP/DOWN/RIGHT ARROWS

, set desired

value then press

ENTER

key to store value. Drive

will accept value,

if valid, then re-display parameter number (i.e. B1-

01, C1-02, etc.)).

7)

Repeat

STEPS 3 - 6

to program remaining

parameters per application requirements.

8)

When complete, press

ESC

key until left-most part

of drive’s display shows

F

.

DRV

LED will also be lit.

V1000 DRIVE IS NOW READY TO RUN.

SEQUENCE OF OPERATION

Refer to the Unit Submittal for a detailed sequence of

operation, performance, and wiring schematic.

The typical sequence of operation is that upon a call

for dehumidification, the pre-cooling coil is active and

cools the process air to the temperature shown in the

submittal. The dehumidification wheel bypass damper

modulates partially closed to produce the correct

proportion of process air through the wheel and bypass.

The regeneration heat source modulates to maintain the

humidity setpoint. The process and regen fans modulate

to maintain their supply CFM setpoints.