WHITE DUST

After installation of the Air Cleaner, you may notice

some white dust on tabletops and shelves. Most large

particles such as lint, are too heavy to remain airborne

and tend to settle quickly, never reaching the air cleaner.

This white visible dust is normally referred to as “clean

dust.” As the Air Cleaner is removing the dark and

staining particles from the air, the lint will also be cleaner.

Lint dust is most noticeable on dark furnishings; in

homes containing new carpeting; and where there is a lot

of household traffic from occupants and pets. To reduce

lint dust, use continuous fan operation and keep return

vents unrestricted to create an efficient airflow.

Note:

The Air Cleaner does NOT produce more lint or

dust.

MAINTENANCE

It is important to follow a scheduled maintenance for

maximum performance of the Air Cleaner.

Cell And Prefilter Cleaning

The collecting cells and prefilters must be cleaned on

a regular basis for the Air Cleaner to function at its peak

efficiency. The frequency of cleaning will vary from one

location to another. On average, the cells should be

cleaned every 3 months.

1. Turn off power switch. Open access door and remove

collecting cells and prefilters.

2. Place cells in a laundry tub. Rinse with hot water and

spray completely with DAX Detergent (or a non-

chlorine, non-corrosive, non-abrasive liquid household

detergent.) Allow detergent to run down both sides of

plates and ionizing wires. Let stand for 5 minutes and

rinse with hot water. Repeat process three times.

3. Rinse cells well with hot water (maximum 120°F/49°

C).

4. If dirt remains, let cells soak in a solution of DAX

Detergent and hot water for 30-60 minutes, then rinse.

5. Tilt cells on 45° angle on their short side, with arrows

pointing sideways. Allow to dry completely,

approximately 12-24 hours. A hair dryer may be used

to speed up drying time.

6. To wash prefilters, spray with DAX Detergent, rinse

and let dry. Do not wash in the same water as

collecting cells.

7. Place cells and prefilters back into cabinet. Close door

and turn power switch

ON

. If the performance light

does not come on or arcing occurs, turn Air Cleaner

OFF

and allow air from system fan to dry cells

completely.

Fig. 2 — DAX Detergent

is available from your installer

or dealer.

SERVICE

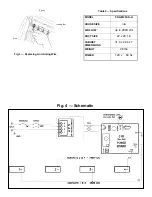

Testing Air Proving Switch (APS)

The APS sensor must protrude into the airstream to

work effectively. The sensor is very sensitive and

operation may be affected by cold temperatures, an air

exchanger, or a fresh air duct connected to the cold air

return near the Air Cleaner.

The APS uses a Triac in its output circuit, which

affects the voltage sine wave. Using a regular digital

voltmeter will give a false reading. To check the output

from the APS, use a true RMS (root mean square) meter

to measure the output at terminals 1 and 4 of the APS.

The output should be between 105 and 115 VAC,

depending on the airflow across the sensor.

A 125 volt neon lamp may be used to test the output

of the APS. Place the leads of the lamp across terminals 1

and 4 of the APS. If the lamp lights, the voltage is

sufficient for proper operation.

When the Air Cleaner is turned on without airflow, the

APS sensor heats up and within 30 seconds, opens the

circuit to turn off the power board. When the fan starts up

(the sensor is cooled), the circuit will close, the power

board is turned on, and the performance light will come

on.

If the power board fails to come on with the fan on,

check that the sensor is properly set in the airstream

behind the cell next to the switch. To check the APS for

proper operation, turn the unit on and activate. The power

board should come on immediately, and then turn off

within 30 seconds as the sensor heats up. When the

system fan is turned on, this should activate the power

board within 10 seconds. Service the sensor carefully.

The sensor leads are 120 V.

Replacing An Air Proving Switch (APS)

Before replacing the APS, turn off the power to the Air

Cleaner at the source.

1. Disconnect wiring from terminals 1, 2, 3, and 4 on the

APS.

2. Release circuit board from plastic spacers by pinching

end of spacer and pulling board out.

CAUTION

Damage to cells may occur if improperly handled or

washed. Do not wash cells in a dishwasher. Never use

any object to clean between the cell plates, as this may

cause damage to plates or ionizing wires. Never place

cell in oven to dry. The edges of the cell may be sharp -

handle with care.

WARNING

Electronic Air Cleaners use high voltage (low

amperage). Only trained personnel should perform

service. Use caution. Electric shock can cause injury

or death. Disconnect power source before replacing

parts.

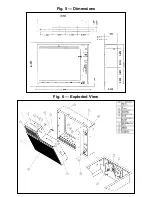

Содержание FS-GM20AS-A

Страница 8: ...Fig 6 Exploded View Fig 5 Dimensions ...