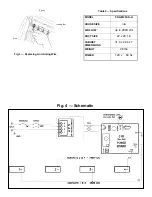

MAJOR COMPONENTS

Cabinet

The cabinet is constructed of 18 gauge steel, painted

with a tough powder-coated, scratch-resistant finish.

Holes are provided to facilitate mounting to the ductwork.

Access to the collecting cells and prefilters is through a

hinged door.

The access door is interlocked to cut power to the unit

when opened.

Prefilters

The washable prefilters, measuring 11½ x 20 inches

(29.21 x 50.8 cm) are constructed of multi-layers of

aluminum mesh for maximum filtration of large particles.

Collecting Cells

The dual voltage collecting cells are constructed of

heavy gauge aluminum to resist rust and damage. The

first stage, the ionizing section, is charged at

approximately 7000 VDC. The collecting plates are

alternately grounded and charged at 4600 VDC. The

arrow on the cells indicates the direction of air flow which

must point toward the rear of the unit.

Electrical Compartment

The electrical compartment contains the system

switch, safety interlock, high voltage power board,

transformer, air proving switch and performance indicator

light.

INSTALLATION

Location

The Air Cleaner should be installed to the return air

duct in the living area of the home or office. It can be

installed either in a wall or ceiling, but not in the floor.

This unit will replace the existing return air grille currently

installed to the main return duct. For the unit to perform

properly, all the return air must pass through the

Electronic Air Cleaner.

In a wall installation, the unit must be installed with

the hinge down.

The return duct or transition should end slightly

behind the finished wall or framing. It should be

approximately 1/4 -1/2 inch (.63 - 1.27 cm) larger than the

air cleaner to allow the back of the unit to slip into the duct

when installing.

When the air duct does not fit the Air Cleaner

opening, a gradual transition is recommended to reduce

air turbulence through the Air Cleaner and to increase its

efficiency. There should not be more than 20º of

expansion used for the transition fitting.

Installation

Carefully remove the Air Cleaner from the carton.

Remove the cells and prefilters from the unit. Remove

the access door from the unit by removing the screw on

the end of the retaining link in the enclosure. Lower the

access door and remove the screws securing the hinge to

the enclosure.

Remove the five screws securing the electrical

compartment cover.

The hole in wall or ceiling should be made to fit the Air

Cleaner opening as closely as possible. The opening

should be framed to provide adequate support for the Air

Cleaner. Before mounting the Air Cleaner, cover the

framing and close the opening to within 1/4 in. (.63 cm) of

the dimension of the rear of the enclosure of the Air

Cleaner. Match the finish to the existing wall.

Mount the Air Cleaner into the framed hole and slide

into the duct until the front flange is flush with the wall.

Secure the Air Cleaner to the frame using sheet metal

screws. Do not overtighten screws as this may distort the

enclosure. Once the unit is secured to the wall, the

access door and retaining link can be replaced.

Wiring

Wiring should only be performed by qualified

personnel only. All wiring must comply with all applicable

codes and standards. The voltage of the power source

must match the voltage indicated on the Air Cleaner. The

Air Cleaner should operate ONLY when the system fan is

running. Make sure the Air Cleaner is properly grounded.

Wire the Air Cleaner directly to the power source. The

APS will power the Air Cleaner when there is sufficient

airflow to activate the sensor.

Connect the black lead of the Air Cleaner to the line

side of power source. Connect the white lead to the

neutral side of the power source. Connect the green lead

to ground. See Fig. 3.

SYSTEM CHECK

Perform the following system check before operation.

1. Replace the prefilters and collecting cells. Close

access door and replace thumb screw.

2. Turn Air Cleaner power switch ON. Ensure system

fan is operating. The performance indicator light

should be lit showing that the Air Cleaner is operating.

Note:

There may be some arcing or snapping sounds

from the collecting cells. This is normal when the unit is

new. In about 2 weeks, as the sharp edges of the cells

become smoother, the arcing will disappear.

OPERATION

The Air Cleaner will run as long as there is airflow

through the ducts. The Air Cleaner will not run if the

system fan is off. For proper operation, follow these

simple steps:

1. Run heating/cooling system fan continuously, and on

low speed if available.

2. Remove any furniture which may block the return air

grille, so that air moves freely to the furnace/ air

conditioner.

3. Check for proper operation of the system fan.

WARNING

Electrical shock can cause injury or death. Be certain

main line disconnect switch is off before wiring.

Содержание FS-GM20AS-A

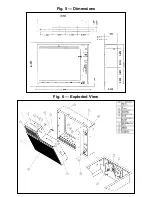

Страница 8: ...Fig 6 Exploded View Fig 5 Dimensions ...