Type ACE95JR

7

Disassembly and Assembly

CAUTIOn

Before removing the valve from the line,

ensure that it is isolated from the gas

supply pressure and that all pressure

has been released from the valve. (The

drain on the inlet filter is convenient

to bleed off gas.) All tank connections

must be closed or sealed in accordance

with your plant’s operating and safety

procedures. If installed, electrical

connections to the explosion proof

switch must be deactivated before

opening the enclosure or disconnecting

the wiring (in accordance with codes

and safety practices).

It is recommended that all seals and diaphragms be

replaced as a matter of good practice whenever a

valve is disassembled and re-assembled. Parts kits

are available through your local Sales Office.

note

When ordering parts, have your model

number, serial number and control

pressure range. Valve information is on

the nameplate (attached to the upper

actuator case).

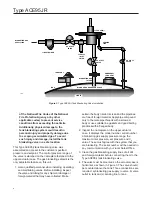

When performing disassembly or re-assembly

operations, refer to Figure 6 for key numbers (unless

otherwise directed).

Disassembly

!

WArnIng

To avoid personal injury resulting from

sudden release of pressure, isolate the

valve from all pressure and cautiously

release trapped pressure from the valve

before attempting disassembly.

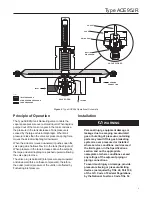

Actuator/Diaphragm Disassembly

1. Remove the actuator cap (key 1) and the spring

load by unthreading the adjusting screw (key 2).

See Figure 4.

2.

Unthread the hex-head screws (key 29) and

remove the lock washers (key 28) and nuts

(key 31) from the upper and lower actuator cases

(keys 33 and 30). Refer to Figure 6.

3. Lift the upper actuator case (key 33) from the

lower actuator case (key 30).

4. If it is necessary to replace the gasket (key 9),

remove the spring case (key 7) and spring case

gasket from the upper actuator case (key 33).

Figure 5.

Cage Assembly

POPPET (STEM)

(KEy 42)

rOllIng DIAPHrAgM

(KEy 38)

W8162

CrOSS-DrIllED HOlE

O-rIng

(KEy 39)

PISTOn

(KEy 37)

W8161

CAgE

(KEy 52)