Type ACE95JR

5

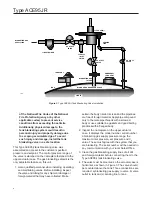

Piping Considerations

note

Piping lengths are best when they are

kept short with a minimum number of

elbows and fittings.

Inlet Piping

CAUTIOn

Undersized piping may inadequately

deliver blanketing gas at the

specified inlet pressure under full

flow conditions. This may result in

unacceptable performance under high

demand conditions.

The blanketing gas supply line should be equipped with

a Number 100 mesh strainer to remove dirt and pipe

scale. Inlet piping must be sized to adequately deliver

blanketing gas at the specified inlet pressure under full

flow conditions.

Outlet Piping

CAUTIOn

Unnecessarily long or restricted outlet

piping may result in poor setpoint control.

Valve outlet is piped into the tank vapor space. Outlet

piping must be full size and self-draining to the tank.

The valve should be situated above and as close as

possible to the tank vapor space for best performance.

Sensing Line

The sensing line should be 1/2 in. / 13 mm tubing or

pipe, must slope toward the tank and should not contain

low points (or traps) that could catch liquid. The sensing

line must enter the tank above the liquid level at a point

that senses the vapor space pressure and is free from

turbulence associated with tank nozzles or vents.

note

Best control is obtained when both

connections to the tank are separate.

If the tank has only one available

nozzle, contact Emerson™. for alternate

methods of installation. A single array

manifold is available for such situations.

Gauges and Shutoff Valves

Inlet gas shutoff valves are desirable for servicing.

If this Type ACE95jr tank blanketing valve was not

ordered with an inlet pressure gauge, it is advisable to

install a gauge between the inlet shutoff valve and the

blanketing valve.

note

Safety considerations may dictate full

port shutoff valves between the tank and

blanketing valve and at the valve inlet.

Startup, Adjustment and Shutdown

note

Tank vents and safety relief valves must

be in place and operating.

Startup

CAUTIOn

Always open the outlet valve before

the inlet valve. Operation in the reverse

order could result in inlet pressure being

applied to the actuator casing, potentially

damaging it.

1.

Open shutoff valves between the blanketing valve

and the tank (both sensing and outlet). See Figure 3.

2.

Slowly open the supply line shutoff valve (to the

blanketing valve) and leave it fully open.

3. Monitor the tank vapor space pressure.

Adjustment

The setpoint of this unit is factory set. Adjustments

should be made in small increments while the unit is

supplying gas to the tank. To change the setpoint:

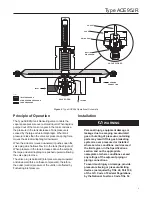

1. Remove the actuator cap (key 1) from the top of

the spring case (key 7). See Figure 4.

2. Loosen the lock nut (key 3) and turn the adjusting

screw (key 2) clockwise to raise the setpoint.

(Turning the screw counter-clockwise lowers

the setpoint.)

3.

Observe the effects of the change.

4. When the adjustment is complete, tighten the lock

nut (key 3) and replace the actuator cap (key 1).