4 | 16 Page

•

The electrical connection of the device shall be

performed according to relevant VDE and local

electricity board regulations.

•

Disconnect the system from the mains before

connecting the device.

•

Add a fuse adapted to the energy requirements.

4.2.1

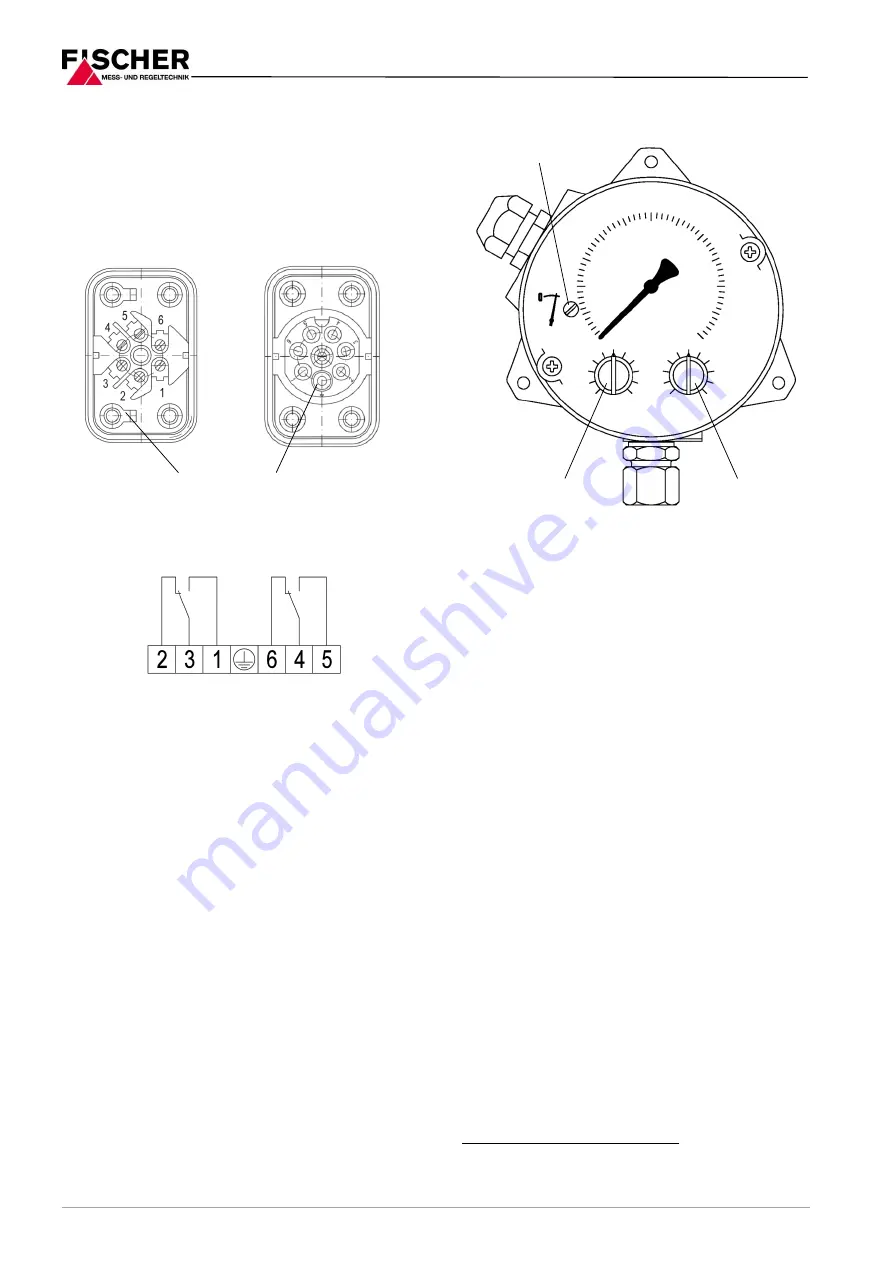

Cable socket and plug connection

Cable socket

Plug connection

4.2.2

Numbered cables

For models with numbered cables, the cable num-

bers correspond with the presented terminal num-

bers.

5

Commissioning

All electrical supply, operating and measuring lines,

and the pressure connections must have been cor-

rectly installed before commissioning. All supply

lines are arranged so that there are no mechanical

forces acting on the device.

Check that the pressure connections do not leak

before commissioning.

5.1

Control Elements

5.2

Zero point correction

Depressurize the measuring chamber.

Remove the hood

Set the measurement value pointer to the zero-

point scale using the zero point correction

screw.

Re-mount the hood.

5.3

Switch point setting

Remove the plug in the hood.

The required switch points can be set guide

value scales according to the markings by us-

ing a screwdriver. The achievable setting accu-

racy is ± 5 %.

1

Replace the plug after completing the settings.

5.4

Function test

Remove both plugs in the hood for testing.

If the unit has two micro-switches, the stated test

steps must be carried out for both switches.

After the test, the switch points need to be reset

acc. to 5.3.

5.4.1

Checking the switch points when the

system is depressurized.

No measurement is shown and the measurement

display points to zero.

Turn the switch point setting button toward the zero-

point until the micro-switch is activated.

1

More accurate settings can be made either in the factory or on

site using suitable aids (test manometer, ohm meter etc.)

Ground connection

Zero-point correction screw

Switch point setting

switch 1

Switch point setting

switch 2

Switch 1

Switch 2

Содержание DS 11

Страница 10: ...10 16 Page 14 Manufacturer s Declarations and Certificates 14 1 EC Declaration of conformity ...

Страница 11: ...11 16 Page 14 2 Certificate functional security SIL2 ...

Страница 12: ...12 16 Page ...

Страница 13: ...13 16 Page 14 3 GL approval ...

Страница 14: ...14 16 Page ...

Страница 15: ...15 16 Page ...