2 | 16 Page

1.6

Inadmissible Modes of Operation

The operational safety of this instrument can only

be guaranteed if it is used as intended. The instru-

ment model must be suitable for the medium used

in the system. The limit values given in the technical

data may not be exceeded.

1.7

Safe working practices for mainte-

nance and installation work

The safety instructions given in this operating man-

ual, any nationally applicable regulations on acci-

dent prevention and any of the operating company's

internal work, operating and safety guidelines must

be observed.

The operating company is responsible for ensuring

that all required maintenance, inspection and instal-

lation work is carried out by qualified specialized

personnel.

1.8

Pictogram explanation

WARNING!

… indicates a potentially dangerous

situation, non-observance of which

could endanger persons, animals, the

environment or objects.

INFORMATION!

… highlights important information ef-

ficient and smooth operation.

TIP!

… indicates recommendations that are

not specifically necessary in certain

situations but which could be useful.

2

Application purpose

The DS 11 is a combined display and switching de-

vice for differential pressure, over-pressure and un-

der-pressure. This series is ideally suited for vari-

ous measuring tasks in industrial applications or the

sanitary field.

Typical applications are measuring differential pres-

sure between the supply and return in heating sys-

tems and monitoring filters and pumps. Pressure

chamber and measuring diaphragms are available

in various materials. This allows the devices to be

adapted to the various requirements.

3

Product and functional description

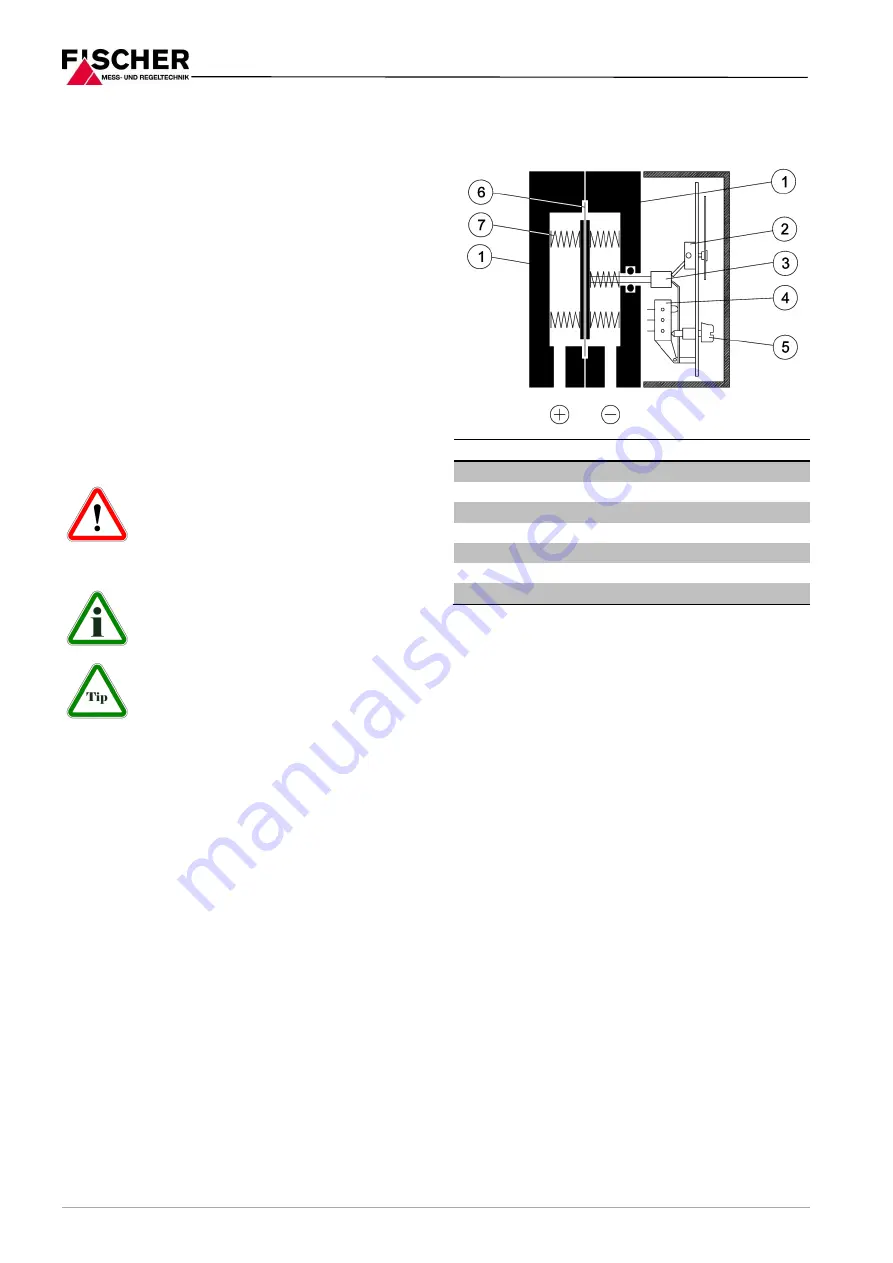

3.1

Function diagram

Item

Description

1

Pressure chamber

2

Motion train

3

Tappet

4

Micro-switch

5

Switch point setting

6

Measuring diaphragm

7

Measuring springs

3.2

Design and mode of operation

A robust and durable membrane measuring instru-

ment is used as a measuring system, which is suit-

able for overpressure and underpressure meas-

urements. The units use the same measuring prin-

ciple for all three measuring applications.

In the rest position, the spring forces on both sides

of the membrane are balanced out. Due to the

pressure or underpressure to be measured, a sin-

gle-sided force is created on the membrane which

shifts the membrane system against the measure-

ment range springs up to equalization of the spring

forces. In case of overload, the membrane supports

against the metallic support surfaces.

A centrally positioned tappet transfers the move-

ment of the membrane system on the motion train

and operating elements of the micro-switches.

4

Installation and assembly

The standard device is designed for wall mounting.

The device can be mounted to even walls using the

assembly foot that is cast to the middle of the de-

vice. It is also possible to fit the device in switch

cabinets using the switch panel installation kit

DZ11.

It is calibrated ex-works for vertical installation; this

is the only allowed installation position.

To ensure safety during installation and mainte-

nance, we recommend installing a suitable shut-off

Содержание DS 11

Страница 10: ...10 16 Page 14 Manufacturer s Declarations and Certificates 14 1 EC Declaration of conformity ...

Страница 11: ...11 16 Page 14 2 Certificate functional security SIL2 ...

Страница 12: ...12 16 Page ...

Страница 13: ...13 16 Page 14 3 GL approval ...

Страница 14: ...14 16 Page ...

Страница 15: ...15 16 Page ...