4150K and 4160K Series

23

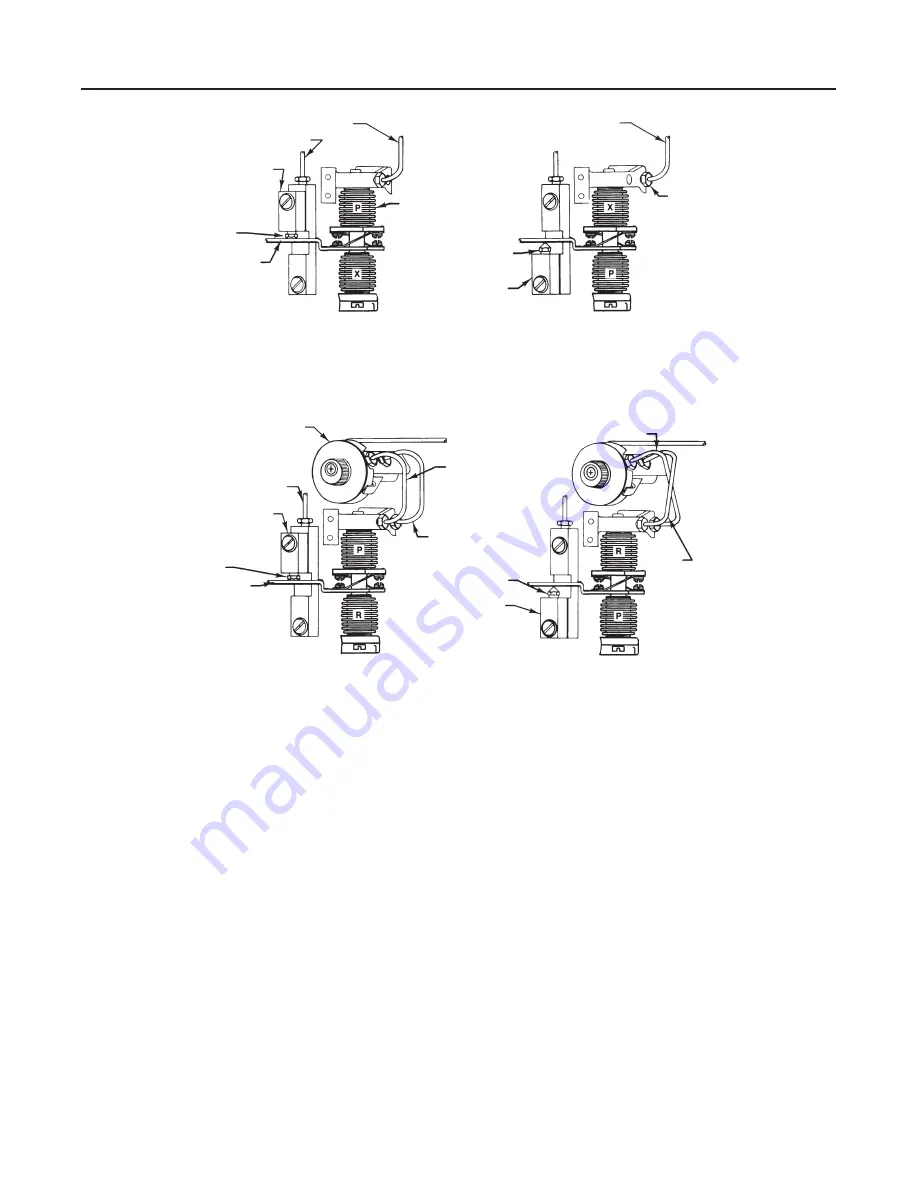

Figure 16. Direct/Reverse Acting Tubing Connections

PROPORTIONAL

TUBING (KEY 104)

RELAY TUBING (KEY 103)

REVERSING

BLOCK (KEY 59)

DIRECT

ACTING

POSITION

BEAM (KEY 44)

BELLOWS

(KEY 52)

REVERSE

ACTING

POSITION

REVERSING

BLOCK

(KEY 59)

PROPORTIONAL TUBING

(KEY 104)

REVERSE

POSITION

RESET VALVE

RELAY TUBING

(KEY 103)

REVERSING

BLOCK (KEY 59)

DIRECT

ACTING

POSITION

BEAM (KEY 44)

PROPORTIONAL

TUBING

(KEY 104)

RESET TUBING

(KEY 117)

REVERSE ACTING

POSITION

REVERSING

BLOCK (KEY 59)

PROPORTIONAL

TUBING

RESET

TUBING

NOTES:

P = PROPORTIONAL

BELLOWS

R = RESET BELLOWS

X = NO PRESSURE

DIRECT ACTING

REVERSE ACTING

DIRECT ACTING

REVERSE ACTING

PROPORTIONALĆONLY CONTROLLER OR TRANSMITTER

PROPORTIONALĆPLUSĆRESET CONTROLLER

B1564-5 / IL

ure 21 or 22), and reconnect them in the opposite

hole.

5. Change the reversing block assembly (key 59):

a. Remove the sealing screw (key 56, figure 21 or

22). Inspect the O-ring (key 55, figure 21 or 22) lo-

cated in the recessed area under the sealing screw

head. Replace the O-ring if necessary.

b. Remove the reversing block screw (key 61, fig-

ure 21 or 22) and reversing block assembly (key 59).

Inspect the O-rings (key 55) located in the recessed

area under the reversing block screw head and be-

tween the reversing block assembly and the calibra-

tion adjuster (key 41, figure 21 or 22). Replace these

O-rings, if necessary.

c. Position the reversing block assembly, with O-

ring, on the calibration adjuster (key 41) so that the

nozzle is on the opposite side of the beam (key 44, fig-

ure 21 or 22) from which it was removed. Properly

position the reversing block assembly so that the

alignment pin engages the hole in the calibration ad-

juster. Install the reversing block screw (key 61) with

O-ring (key 55).

d. Install the sealing screw (key 56) with O-ring in

the hole previously covered by the reversing block as-

sembly.

6. Check all connections for leaks with a soap-and-

water solution. Perform the appropriate calibration pro-

cedures.