20

£

Modifiable parameters located in PROGRAM SETUP MENU

TO VIEW AND MODIFY A PROGRAMMABLE PARAMETER:

Use the NEXT or BACK key to scroll to PROGRAM SETUP. Press the MODE key to enter the sub-

menu showing all program setup parameters. Pressing the MODE key while in the sub-menu will

exit the sub-menu, and the next main menu item will be displayed. While in the sub-menu, pressing

the NEXT key will scroll forward through the sub-menu. Pressing the BACK key will scroll back-

ward through the sub-menu. When a modifiable parameter is displayed, the top line will indicate

MDFY TO CHANGE while the bottom line will indicate the current item and its current value.

Pressing the RESET/MDFY key will allow the displayed parameter to be modified. The item to be

modified will move to the top line while its value will remain on the bottom line. At an infrequent

rate, the top line will indicate MDFY TO SAVE. Use the NEXT or BACK keys to select the value to

suit the application and when done, press the RESET/MDFY to save the value to memory.

Note 1:

Not affected by 8 hour burn-in or LOCK SETTINGS.

Refer to SYSTEM INFO Sub Menu, page 27, for language selection.

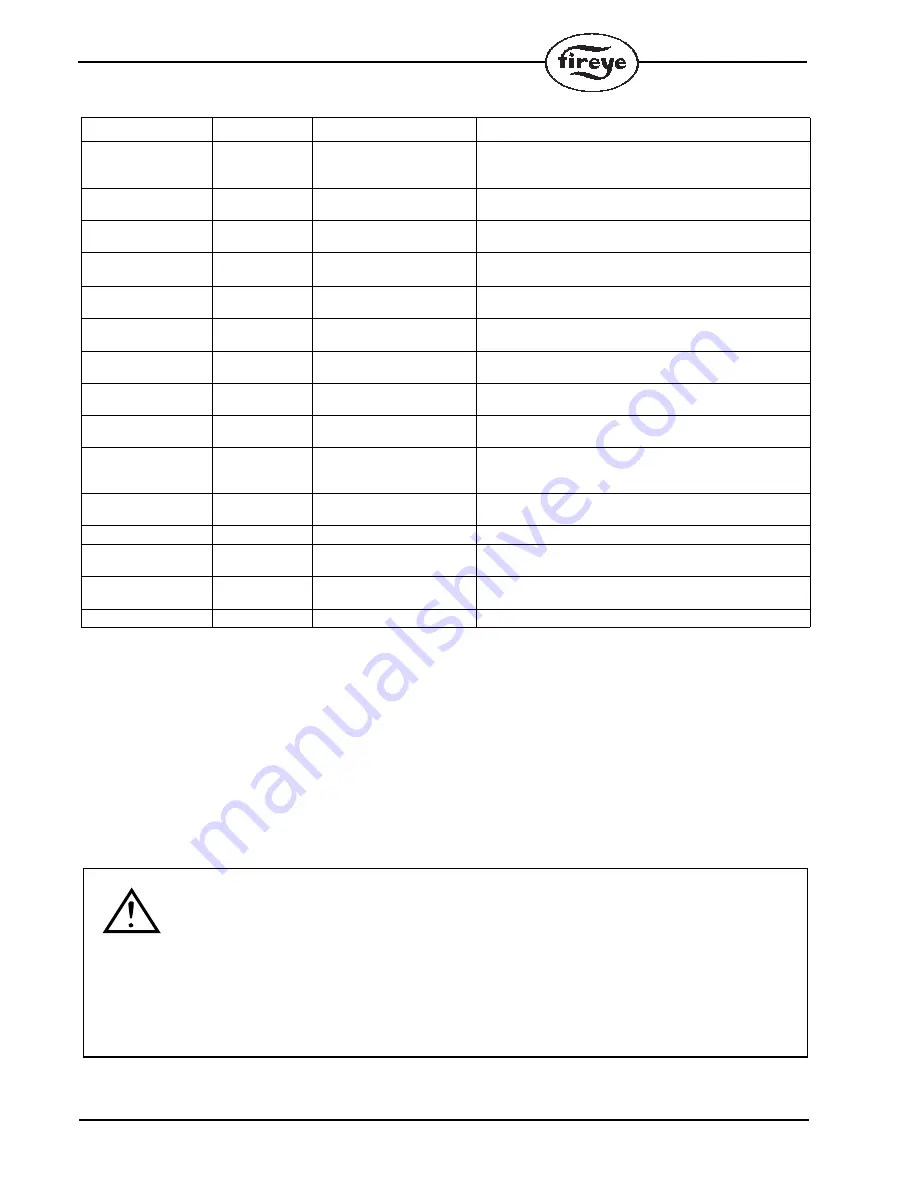

Parameter

Factory Default

Range

Description

Purge time

00:30s

0:30s – 60:00m, 15 second

increments.

(0:00s - 60:00m in YP3XX)

Applies to open damper purge time in YP1XX and YP2XX pro-

grammers and to low fire start time in YP3XX programmers

Count method

DOWN

UP, DOWN

1

Time counts UP to final value or DOWN to zero from starting

value. This setting will apply to all timer values.

Prove 3-P open at start

NO

YES, NO

Prevents jumped terminals. Requires the 3-P circuit to be

open at the start of a cycle.

PTFI*MTFI timing

10/10*10/15

YP113 = 5/5*3/5

See chart on page 15

Applies to terminals 5 and 6 operation during PTFI and MTFI.

Terminal 6 interrupted

or intermittent

INTRP

INTRP, INTMT

Provide interrupted or intermittent operation on terminal 6.

Prove M-8 open

NO

YES, NO

If YES, M-8 must be open at start of open damper purge

period. (YP1XX Series only).

Prove M-D open

NO

YES, NO

If YES, M-D must be open at end of open damper purge

period. Does not apply to YP3XX Series.

Post purge

0:15

0:15s - 1:00m, 5 second

increments.

Selects Post Purge time

3-P Recycle

YES

YES, NO

Applies to YP3XX series only. Allows non-recycle operation of

3-P circuit.

M-D WAIT 10m

YES

YES, NO

Select YES for lockout on M-D open for 10 minutes. Select

NO for indefinite wait for M-D to close. This wait time applies

prior to pilot trial for ignition.

PROVE M-D TFI

NO

YES, NO

Select YES to force lockout on M-D opening during PTFI and

MTFI

Baud rate

9600

4800, 9600, 19200

1

Sets communication rate

Unit address

00

00-31

1

Multi-drop requires unique addressing. Lowest address

allowed for modbus is 01

Lock Settings

NO

YES, NO

Parameters can be stored to memory before automatic 8 hour

store.

DO IR LEARN

NO

YES, NO

1

Select YES to activate IR LEARN process. See IR operation.

All programmed settings become permanent if the BurnerLogix system has been powered

continuously and 8 hours of main burner (terminal 7) on time has been accumulated. If the

AC power is removed prior to accumulating 8 hours of main burner on time, the system

burn-in time clock will be reset to zero. It is not necessary for the main burner on time to be

continuous. The BurnerLogix accumulates burner on time in seconds. For example, assume

power has been applied for 10 hours and the main burner has been on for 4 hours. If the AC

power is removed and then restored the accumulated main burner on time will be reset to 0.

If necessary, the programmed settings can be made to become permanent anytime before

the required 8 hours of main burner on time through the use of the optional keypad and the

LOCK SETTINGS option under the PROGRAM SETUP sub menu.